Can anyone tell me the correct way to do a 45 degree full pen prep on an S beam. If I go with the thickest part of the flange and lay out my cut the thinnest part is way over a 45. If I go with the thinnest part of the flange to lay out my cut the thickest part isn't even a 30 degree. Really confused on how this should be done.

Thanks, Travis

Hello Travis, by chance can you provide a picture of what you are describing. Myself and others have likely done a whole lot of these sorts of preps., but short of including a pictorial with accompanying text, it might be difficult to describe, at least for me. Best regards, Allan

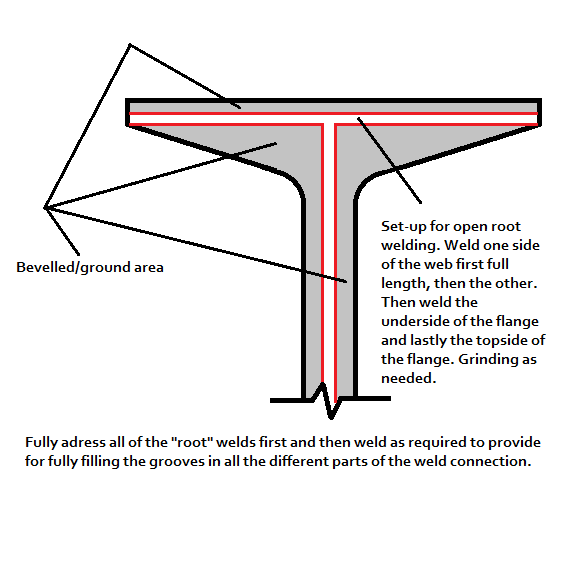

Hello again Travis, I thought about your question a bit and came up with a dwg. that I believe may be what you are inquiring about. When you see it you can certainly expand upon whether this is correct or not. Best regards, Allan

Hello Allen, thank for your help on this. Now if I am looking at the drawing you attached correctly, this is basically showing the prep for a double bevel open root CJP of an S beam, is that correct? If so, it doesn't quite get me to where I need to be. The drawing is only calling for a single bevel at a 45 degree, so I am just assuming it will a 1/4" root with backing or backing weld. We are just prepping the beam to be welded in the field. I would post the section of the drawing that shows the required prep but don't know how.

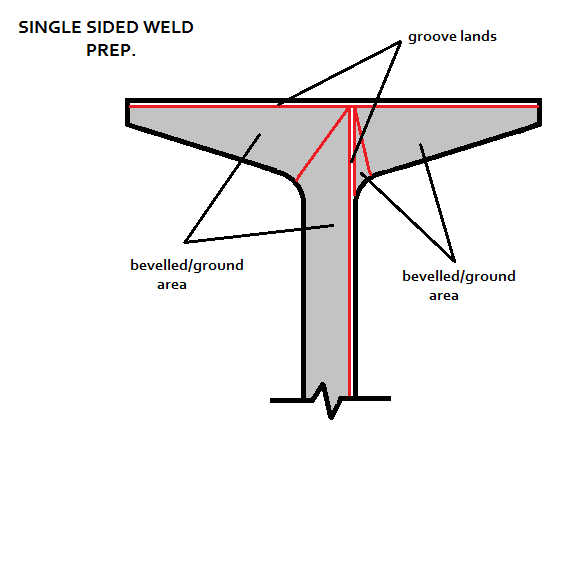

Okay Travis, now I follow what you are saying. Yes, due to the variance in the thickness of the top flange of this particular shape it does pose an "interesting" challenge if you are doing a single side prep. I've modified my original drawing to represent what I believe is a more "correct" description. Best regards, Allan

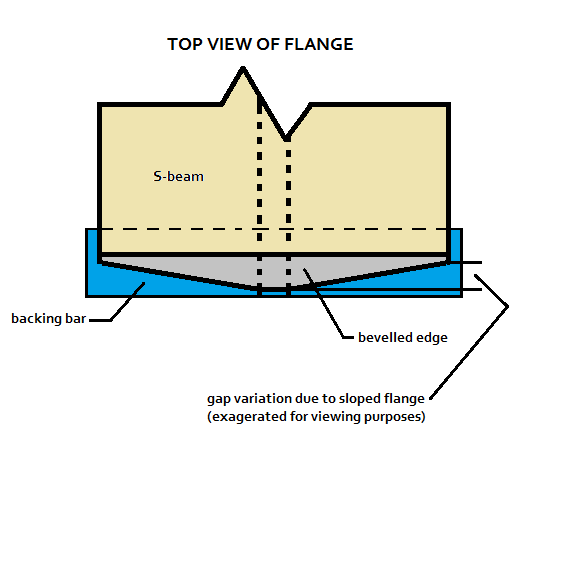

Yes Allen I believe we are on the same page now. Im going to try to attach to pics here that will hopefully make my question all that much more clear. The one of the top flange view is where most of my question lays. Should it look like the sketch? That is the only way I can see getting a full 45 degree bevel over the full ranges of thickness. To have a somewhat arched bevel. Thanks for all your help

file:///C:/Documents%20and%20Settings/Shop%20Supervisor/My%20Documents/Downloads/image1(4).JPG

file:///C:/Documents%20and%20Settings/Shop%20Supervisor/My%20Documents/Downloads/image2.JPG

Travis I know this doesn't answer your specific question, but if the joint could be fit up first with no bevel prep, and then gouged with an air arc to make the grooves on one side, welded, and then back-gouged and back-welded, it would likely be easier, faster, and cheaper than beveling beforehand.

Blaster,I wish we had that option, but this is just a shop prep to be welded in the field. So we have to go ahead with the prep and hope we are doing it correctly.

Prepare the bevels as straight cuts with no root face. The root opening will vary, wide at the out side edges, narrower at the web. That being the case, prepare the groove with the proper root opening at the web and let the root opening widen as the groove approaches the free edges. The backing will have to be clamped to conform to the taper of the flanges. It isn't a big deal. If I remember correctly, the taper is 1 in 12, so it isn't that dramatic.

Best regards - Al

Hi Al, so let me see if I got this correctly. I should figure my 45 from the thickest section of the flange and the cut line along the outside of the flange should be straight? After cutting, the thick area of the flange will remain the same in length but as the flange thins some length will be removed giving it a very slight V appearance? Is this correct?

Thanks

You are over thinking the situation.

To review: you are beveling the end of the beam so it can be welded to another member( a column flange, etc.). Solution: you strike a line across the flange far enough from the end so that the 45 degree bevel cuts to the access hole in the beam web without leaving a root face. See embedded sketch.

Best regards - Al

Yeah I probably am, just want to make sure Im doing it right. Thanks for the help

Well Al, it appears that I am thinking "pre-access" days. Thank you for pointing that out. By chance does this sketch somewhat "show" what you are describing to Travis? Regards, Allan

P. S. I just noticed that your dwg. does show what I included, sorry

The more sketches, the better. At least we are singing from the same sheet of music! I think the situation is clarified pretty well using the sketchs you provided and the ones I provided.

Best regards - Al

Hello again Al, I'll certainly agree that it's been awhile since I have been associated in a full-time manner with industry on this sort of thing but how often is this a pre-field detail or one that is applied by the erection/welding crew doing the install these days? My foggy memory seems to come to me that we would not provide this sort of prep. on something that was going to be done in the field as they seemed to want to decide on their own particular approach. Am I all wet in my thinking? While I am asking these questions, I do understand that joint details and such are often called out in D1.1 or whichever applicable code is invoked or that the particular detail might be selected by the engineer. Thanks, Allan

Beams are usually prepped by the fabricator. It is too expensive to do it in the field and you never know who is going to get hold of the torch. The edge could look like a drunken beaver gnawed on it or it could be a smooth as silk.

The erector wants to throw up the iron, not worry about holding up the crane and crew while someone cuts and grinds the bevel on each beam before sending up. It's all about the money and time is money.

Best regards - Al

Al

you are correct, but so wrong

the job site superintendent must know and make the right call

been on both sides

wish I was 100 people and able to do every job

or just hire 30 people

like you and Lar

but life is not that way

nor is business

just my thoughts

take Allen as a trainee

sincerely,

Kent

Every time we had to bevel a flange because the fabricator missed it, we got paid an "extra."

I have never been on a job where the erector beveled the beams "by design."

Usually you could hear the super cursing up a storm because the rig had to wait for the beam to be beveled. Usually it would be done after the iron was erected where it was three times harder because you didn't want to gouge the column or throw dross all over the column flange where I had to weld.

Al

Al,

your correct

but not even our very good friend Henry is not perfect

(great role model

but we all make mistakes)

I have done shop work where the field people did an utter FUBAR

and went out and fixed it

and as you said was in the field and fixed the shop FUBAR

but live and learn

I wish to do both

as long as I can

sincerely,

Kent

A day when nothing new is learned or discovered is a day wasted.

That's why I love this work. Everyday is an opportunity for me to see, hear, or learn something new. The more I learn, the more I realize I really know very little.

No one can know everything. They may think they know everything, but they are only deluding themselves. It brings to mind the definition of an expert: "An expert is someone that knows more and more about less and less until he knows everything about nothing."

Speaking of Henry, has any one heard from him recently?

Best regards - Al

Al,

have not heard from Henry

will dig through my files

and see if I have some contact info

somewhere

sincerely,

Kent

Let us know how he's doing.

Al

but we all make mistakes)

but we all make mistakes)