So, Kevin asked about arc blow information to help out a welding school he is part of. They are having some issues that they have not been able to resolve and thus far those assisting them have been of no help.

Let's see what we can do.

Now, Kevin, we need to know a few things:

1) Welding Process: SMAW, FCAW, GMAW, GTAW, etc.

2) Welding Procedures: Volts, amps/wire feed speed, electrode class and size, gas for shielding (75/25, 90/10, 100% CO2, etc) and its flow rate,

3) Materials to be joined: grade and thickness

4) Joint configuration: T-joint, butt joint, corner joint, etc.

5) Size of work lead and how is it attached to the member in process?

6) A picture would really be nice if you could.

He Is In Control, Have a Great Day, Brent

It is late and I have to pack for some more travel early in the morning. So, being lazy; try a search of this site and previous posts. We have covered this subject several times.

Best regards - Al

We already told him about that available option but thought it might help if we could get more info about his specific problem. There may be a simple solution.

Brent

Brent,

He noted his booths are grounded together. I don't know that I have ever seen that before (I may have missed it). Everywhere I have been each welder has been grounded to the particular work or weld table. May be a dumb question, but is there any possibility of back feed between welders on a common ground? Not sure with all the new electronic gizmos in newer welders.

Garrett

Garrett,

I was thinking the same thing. In fact, I think that was discussed in one of the previous threads dealing with arc blow. Hopefully some of the more 'educated' within that arena will chime in.

I know when doing larger projects in the shop or field we have had multiple machines grounded to the same member but those are usually pretty good sized components; petroleum storage tanks, large equipment, larger structural members and/or the entire building being erected.

Using several machines grounded together with a common ground in welding booths may be worth taking a look at.

Brent

ABOUT THE BOOTHS BEING ALL GROUNDED TOGETHER ? WE DID THAT TO TRY TO CHANGE THE ARC BLOW,SOMEONE GAVE US THE IDEA I GUESS? BUT THE ARC BLOW HAD ALREADY BEGAIN. AND THATS THE ONLY THING THAT HAS CHANGED FROM THE FIRST START OF ARC BLOW. SO FARE. SHOULD WE CHANGE BACK BEFORE TRYING ANY THING MORE? ALSO WE RAN A TEST PLATE OUT OF THE SHOP OFF MY WELDING RIGG AND NO ARC BLOW . WITH THE SAME TEST SET. SO WE TOOK THE WORK IN THE SHOP NOT IN THE BOOTH. STIL NO ARC BLOW.AS SOON WE PUT THE TEST IN THE BOOTH ON THE BOOTHS FIXTURE AN STILL RUNNIING OF THE RIGGS POWER.THE ARC BLOW CAME BACK! WHAT THE HE***** IS GOING ON? ARE THE BOOTHS THAT MAGNETIC TO DO THIS ? ALL ALONE BY ITS SELF. WITH NO POWER FROM IN SIDE THE SHOP IN PLAY. ALL TRY ANYTHING NOW? SIN.KEVIN.

Have you checked the booths with a gauss gauge? Seems to me all other variables have been checked. What is the structure of the building? Any anomalous electrical problems? Checked resistance?

Yes, pictures showing the exact welding setup, including the work clamp location and both lead runs.

BRENT THANK YOU FOR YOUR HELP. I AM YUST THE CEO OF ARE COMPANY SO ALL I CAN SAY IS MY LEAD INSTRUCTOR IS ON HIS WAY TO HELP WITH ANSWERS. I CAN TELL YOU IT ALL 7018 SMAW ROD ON STANDERD SERT. TEST PLATE CONFIGURATION . MORE WHEN HE,S HERE. ALL ARE WELDERS ARE LINCOLN INVERTEC V275-S IN A ROW OF 8 BOOTHS GROUNDED TO GETHER . AND MY SPELLING HAS ARC BLOW KNOW TO I THINK. THE LEADS ARE 2.0 GAGE WIRE WITH STANDARD CLAMPS. THE WELDERS ARE WIRED FOR 3PHS.AND ARE MOUNTED IN EACH BOOTH ON WALL NEXT TO WELDING FIXTURES. THATS ALL FOR KNOW. THANKS. THE MAT. IS 1 IN.X6X3 FOR 3G SERTS.

AND THE ROD IS 1/8 SIZE THE JIONT CONG.IS A V GROVE BUTT YOINT WITH BACKING PLATE.IS 1/4X1.5 WIDE. AND MY GUY IS HERE KNOW.IS THERE MORE YOU NEED TO ASK.

A note of caution; if welders switch between polarities the voltage could double because the connections would be in series. Arc blow can be mitigated by using a cable with two work clamps. Clamp One at the weld end and the other to the table or fixture to create a circular magnetic field instead of concentrating it at one end.

Would this be related to my note above about using a common ground between all the tables? Just curious.

THANKS. I WILL DOUBLE CHECK ON THE POLARITIES AND THE TWO GROUND CLAMP CABLE SOUNDS LIKE A GOOD THING TO TRY? IM ON THE WAY TO DOCTORS APP. I WILL TELL MY GUYS YOUR IDEA . THANKS 357MAX!

THANKS. I WIILL CHECK IT OUT!

THANK FOR ALL THE NEW INFO. AND WERE WORKING ON SOME PICTURES. I WILL NEED HELP ON POSTING THEM TALKING ME THROUGH IT WOULD BE A MUST FOR MY SKILLS? RESP.KEVIN

By welderbrent

By welderbrent  Date

Date 05-28-2016 04:18

Edited 05-28-2016 04:22

When you get them ready follow this:

1) do a post or go to a previous post of yours in this thread,

2) go to the bottom of the post after it has been posted and look at the toolbar along the bottom edge,

3) click on the button that says 'attach',

4) it will ask you where to get it from with a browse option (I think it says 'choose file'),

5) you should be able to work through it and attach your photo(s) from your files.

Brent

I assume you have already tried degauss-ing the jigs/fixtures, and booth frames.

WE HAVE A HAND HELD GAUSS METER AND GOT READINGS OVER THE 20+ LIMITS. ARE BOOTHS ARE MAGNETIZED! THIS WHAT WE DID .ALL THE GOOD INFO. ALL OF YOU HAVE PIONTED ME TO WAS GOOD STUFF.SO ON AN OLD FORUM TOPIC ON ARC BLOW SOMETIME AROUND MAY OF 2015. I THINK IT WAS LAWRENCE! ON MAGNETIZED FIXTURES HE SAID TRAINING FIXTURES OFTEN BECOME MAGNETZED... SO HE SAID RUNNING AC CURRENT THROUGH EACH PART OF THE FIXTURE WILL HELP BREAK THAT UP.... A DEAD SHORT WITH A 5/32 ELECTRODE AND 100 AMPS UNTIL IT MELTS IS A VERY QUICK WAY TO BREAK UP MAGNETISM IN THE FIXTURE...SO LAST NIGHT ME AND MY LEAD WELDER HOWS NAME ALSO IS KEVIN! SET UP MY BIG DIIAL AN ARC AC MILLER WELDER. IT WOULD HANDLE THAT JOB WELL..IN ARE BOOTHS THERE IS A MAIN POLE IN WITCH ALL THE FXTURES AND WORK TABLE SLIDES UP AN DOWN.ALSO WE ARE BACK TO EACH FIXTUR IS GROUNDED SEPARATE. WE HOOKED THE NEGATIVE LEAD TO THE BASE OF THE POLE WITH FIXTURES IN PLACE AND WE TOOK THE POSITVE ELECTRODE HOOKED TO THE TOP OF POLE WIITH A DEAD SHORT UNTILL IT MELTED PRETTY GOOD!!! AND THEN WE SET UP THE STANDARD TEST PLATE CONFIGRATOIN THAT WE HAVE ALWAYS USED AND I STILL CANT BELEAVE IT.. BUT THE ARC BLOW BACK WAS ALMOST COMPLETELY GONE!! THERE WAS A SLITE BIT OF BLOW AT THE VERRY END OF THE WELD. TEST...SO TODAY ILL BE REGROUNDING ALL THE FIXTURES. WE JUST DID ONE BOOTH LASTNIGHT.. AND THEN WE BE SHOCKING THE SH.......T OUT OF ALL THERE LITTLE BUTTS TODAY!! I GUESS WE WAIT AND SEE HOW LONG IT WILL LAST.. I HAVE NO PROBLEM SHOCKING THEM ON A REGULARE BASES IF IT WELL KEEP THE ARC BLOW UNDER CONTROLL MOST OF THE TIME!! I THANK YOU ALL FOR YOUR INPUT. IM OFF TO THE LAB TO DO A LITTLE BIT OF SHOCK TREATMENT ON MY LITTLE WELDING SCHOOL ....WILL TALK SOON.. HOPEFULLY THIS JUST MAY BE THE FIX WE WERE LOOKING FOR!!!!!! AND WILL BE KEEPING ALL FINGERS CROSSED!! BEST REGARDS...... KEVIN AND THE OTHER KEVIN TO.....

Glad it helped, but pack a lunch my friend because the arc blow thing will be ongoing :)

But you will get better and better at dealing with it.

By Northweldor

By Northweldor  Date

Date 05-29-2016 14:00

Edited 05-29-2016 14:03

Glad you found the problem and solution

Hallo this is kevin. back to the scene of the crime! 17 days later. we are about to reopen are school. all the poles&fixtures have ben de magnetized? so we will soon see if this works and for how long? Lawrence had the idea of how to demag. the booths. and it is working. so fare.and in the mean time i have ben locking at all the info. on modifying the fixtures that Northweldor sent me. and i think there are some good ideas that we should try. even if this last awhile. i feel good about what we have done so fare. Thanks for the info. Northweldor.and until we get some real results from running the test plates in all the booths at the same time i will stop flapping my gums! so i just wanted to thank all of you for your help in this matter! and i have not forgot Welderbrent for getting me started in this forum! and setting me up in this forum with my own topic! when i started the very first time it was a mess. so i'm going to let all of you go for now. i will let you all now the out come soon.

Best Regards.Kevin

Kevin, Glad everything is working out!

Good luck! Fingers crossed

Tyrone

Hey Kevin,

Glad to hear you are getting some easier welds... In my opinion there is a silver lining to your cloud of arc-blow :) Meaning that It will come back and your students will be forced to deal with it, thereby learning important things for the trade.

The dead short technique worked well enough for us when things were really bad... But never lasted very long.

So we kept a 50 lb. box of E6011 electrodes on hand at all times.... When we begin to experience arc-blow we break out the 6011 and make a series of AC welds, moving the work lead to various points in the welding fixture. This way the AC current flows through all parts of the fixture and has a good effect at breaking up magnetism when it's not too severe.

By 803056

By 803056  Date

Date 06-19-2016 18:39

Edited 06-19-2016 18:51

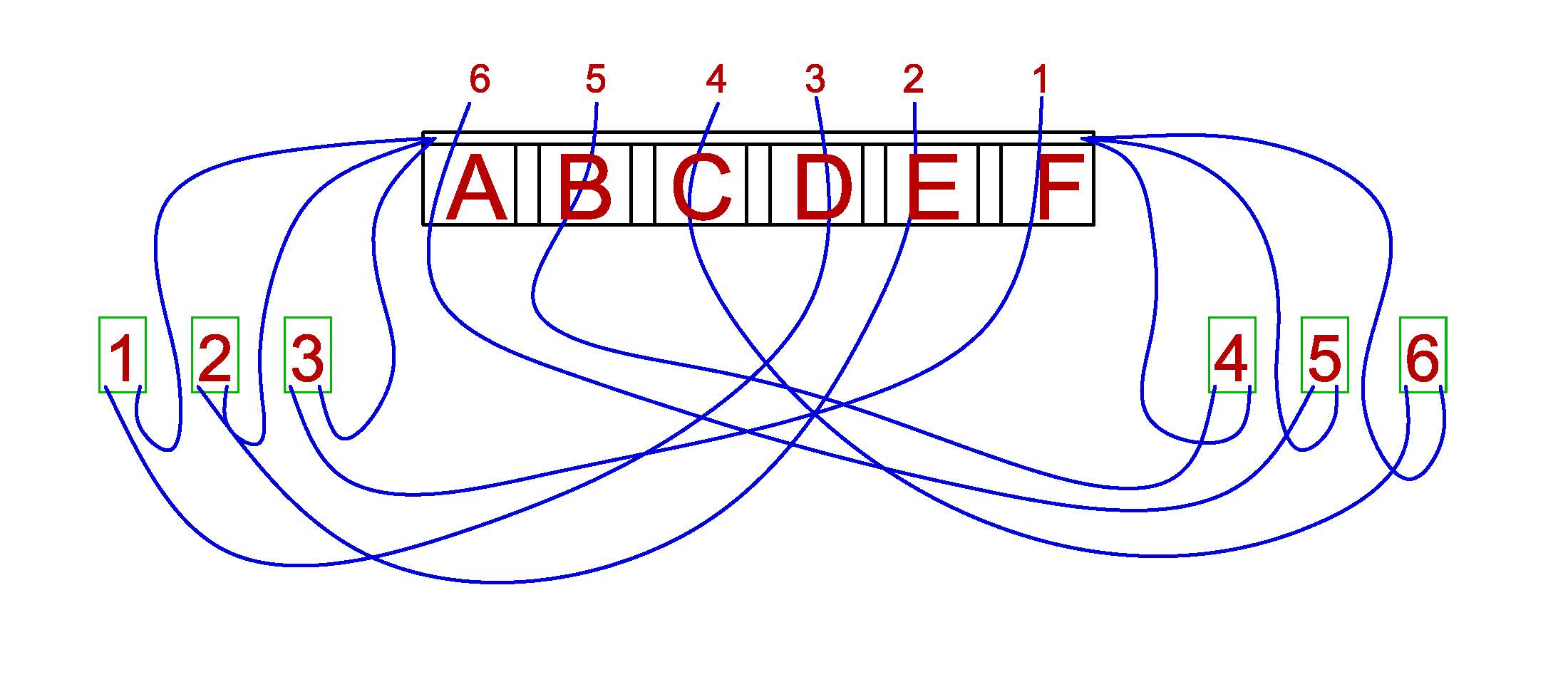

Try this. The principal is called "bucking currents" meaning that the current from each welding machine is counter acted by a current in the opposite direction from another welding machine. In general, most welders use current that is approximately on the same order of magnitude if they are using the same diameter electrode. Even if they are using a different diameter and different amperage, the currents counter each other thereby reducing the affects of the magnetic field. In effect, the current from welding machines 1, 2, and 3 are countered by the current from welding machines 4, 5, and 6. One basic assumption is all the work benches are interconnected.

I use the same approach when more than one welder is welding on the same structural member or piece of equipment. It works and is very effective.

Al

If you don't know how to post the pictures (images), don't worry because we will walk you through the routine. If this is not possible, then good luck and btw, Welcome to the AWS Welding Forum...

If you don't know how to post the pictures (images), don't worry because we will walk you through the routine. If this is not possible, then good luck and btw, Welcome to the AWS Welding Forum...

Well, that's it for now because I need to go and rest a bit.

Well, that's it for now because I need to go and rest a bit.