Thank you a lot keeping discussion about subject...

I want to answer or note your 10 sentences,

1- Yes you are right but in AWS D1.1 figure 5.4 (F) it is pointed.

2- Definitely I agree with you.

3- Yes he did.

4- Yes we have got PQR and it was accepted.

5- ok

6- Until now it is OK but I do not know what happen if we have earthquake!!! Considratin Siesmic loading.

7- In square edge preparation we have only wire brushing the weld bead surface.

8- Yes

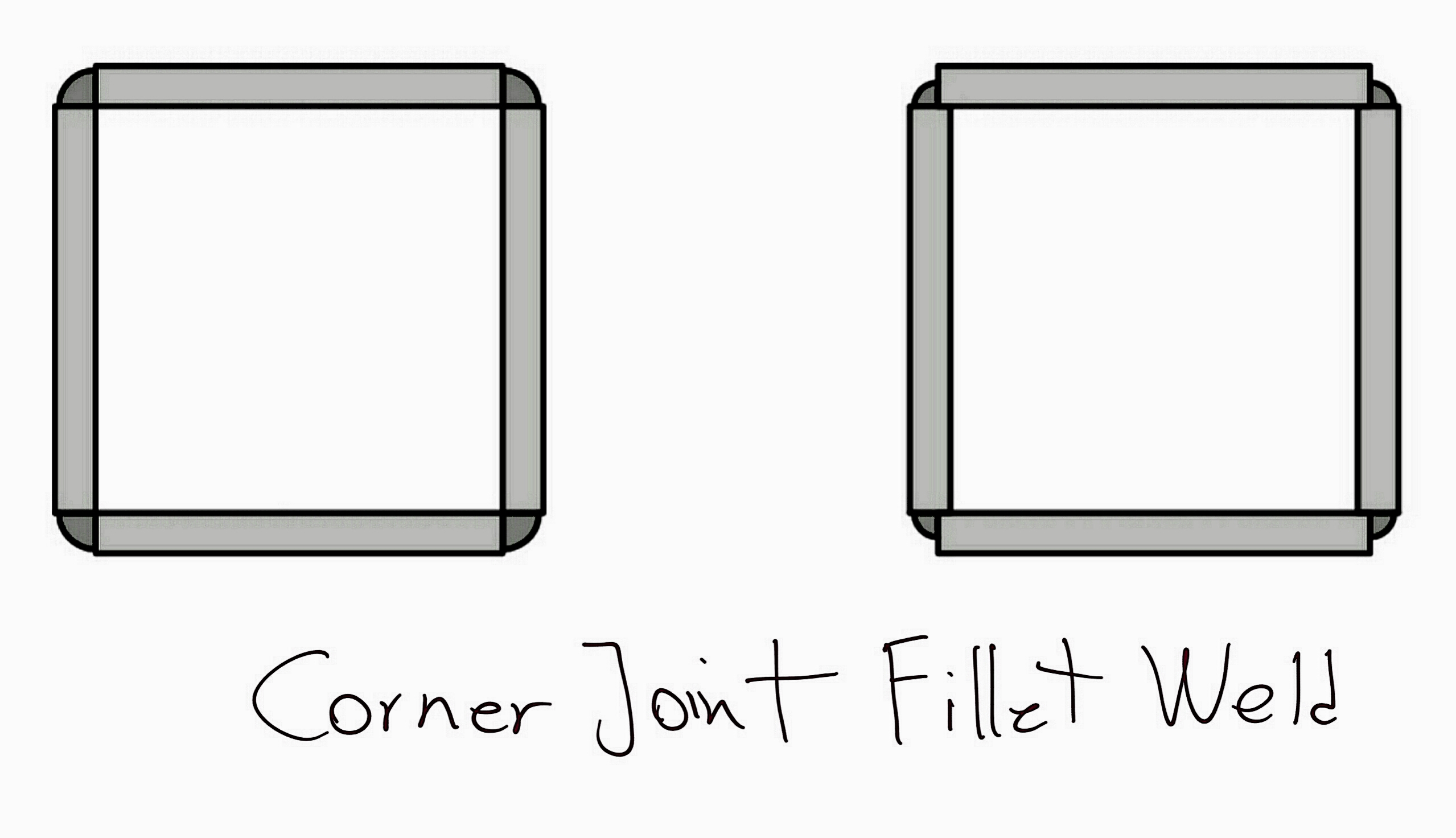

9- We have not sure what happens within it! I will show you a cross section of that joint.

10- Yep