Here is a link to a website with more information or at least a couple of videos and a good sketch of the bridge once completed.

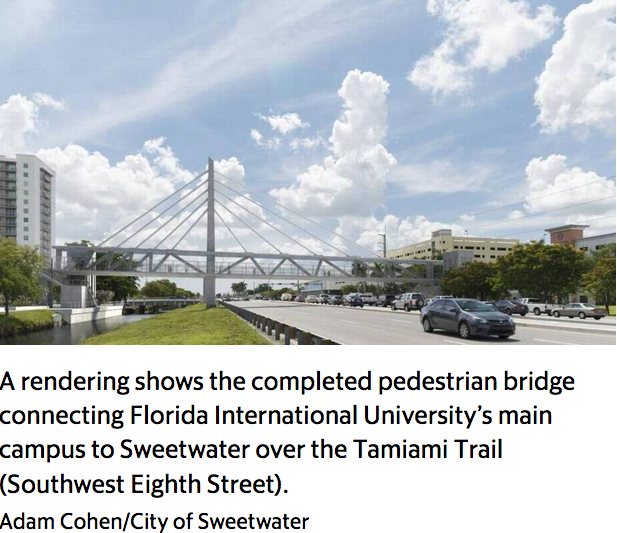

http://www.miamiherald.com/news/local/community/miami-dade/west-miami-dade/article204506084.html#0It is a post tension stayed bridge. I guess they thought the span was stout enough to support its own weight until the tower and stays were placed. 930 tons is a lot of dead weight. Once in position the lower deck would be in tension while the upper deck would be in compression without the stays in place. The diagonal web members would be in tension or compression. The loads could be enormously high in the web members and without sufficient rebar to transfer those loads into the top and bottom decks, the diagonals could punch through the decks and collapse.

The nature of the loading could also be change dramatically once the stays are in place and tensioned.

As mentioned, it is too early to know with any certainty. There was a peer review performed by third party engineering firm from what I've read. That is pretty standard practice, but whether it was a review of the bridge after completion or during erection wasn't clarified.

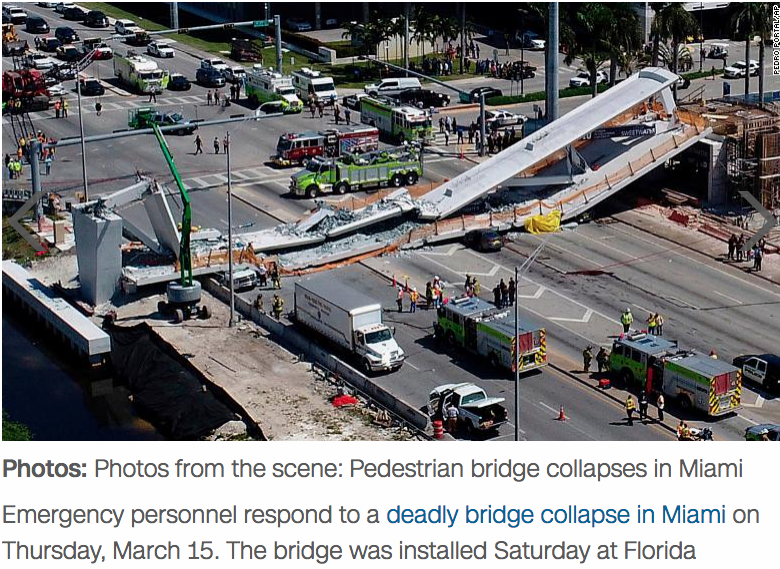

It would be reasonable to assume the erection plan would consider the dead load of the span during erection and its stability until the stays were placed. However, from the video, it appears the collapse was sudden and with little warning to those working on it.

They say there was a voice mail stating there were cracks observed, but I didn't hear where the cracks were seen. Transverse cracks in the lower deck could be expected since it would have been loaded in tension. The post tension cables are designed to carry the tensile stresses. Concrete in tension is not very efficient. That's why rebar are placed where the tensile forces are developed. However, whether the tension cables were designed to carry the dead load of the entire span without the stays in place is another question that has to be reviewed and answered.

As mentioned earlier, the diagonal web members are in tension or compression both during the erection phase and once the bridge was completed, but the nature of the loading could be changed once the stays are in place. The magnitude of the loads in the diagonal web members would be altered significantly once the stays were in place. That leads to the question whether the forces developed by the diagonal web members at the connections with the upper and lower decks were appropriately accounted for. Without proper reinforcing, there could have been a punch through failure at the connection of either the upper or lower decks.

It would not be surprising to learn the root cause was a failure in communication between the different parties involved. The designer designed the bridge and sized the members based on the loads anticipated when the bridge was complete. A different group considered the means and methods of erection. Whether the lines of communications were open and efficient is something that would need to be checked. A failure to communicate has been a problem in the past where structural failures were involved. Think of the the walkway in the Tea Room collapse.

Due consideration must be given to the changes in loading during transportation, temporarily before the stays are placed, and once the bridge was completed. That would include supporting the span as it was moved from the sideline where it was constructed to its final position on the piers. The loads would change because of the location of the supports during transportation and the location of the supports once the span was placed in its final location on the piers. During transportation the supports were located (from what I could see in the photographs, about 1/4 of the span's length from each end. The portions cantilevered beyond the supports would counter the weight of the spans between the two supports. Once in position on the piers the load is supported at the ends of the span, again changing the nature of the loads. It makes it easier to understand the nature of the loads and deflection of the members if one thinks of the span as a wet noodle. The members flex and deform much like a wet noodle. See attached sketch.