By Lawrence

By Lawrence  Date

Date 05-11-2018 13:01

Edited 05-11-2018 13:07

Hi Kallie,

I'm assuming that at this time you are testing with plate, since you are doing positions one at a time, so this response is based on that assumption.

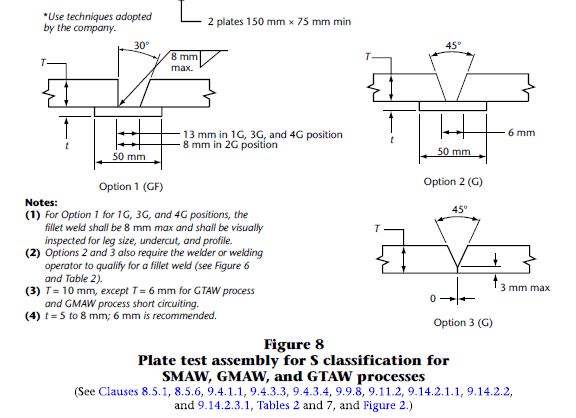

The typical test assembly for CWB plate is a 3/8" single bevel (CSA W47 Figure 8) The most common test assembly is the single bevel (option 1) but a V-groove is also available (option 2).... Option 1 is most often used because it will quality for Grooves and Fillets, whereas option 2 requires a separate fillet performance qualification test.

1. Ensure your backing strip extends at least an inch beyond the test assembly at both ends so that you can use them as run-tabs... Using run-tabs has benefits for the test taker, meaning the welder can start off on the tab, get control of the arc and get a solid weld pool going in the beginning and also finish beyond the end of the joint. This helps for root fusion and also visual inspection of the entire length of the weld.

2. Option 1 requires a "split root" Meaning that a fillet must be placed (with a size requirement) on the 90 degree side of the single assembly, without touching the bevel on the other side. Gun/rod angle here is critical to get that root fusion, with GMAW, this is the pass that stick-out must be most tightly controlled, meaning ***Short stickout*** to get maximum current.

3. Root passes require a restart...... The test assembly is marked by the test conductor, a specific spot for the stop/restart to occur.

Technique on stopping and starting here is also critical to get fusion, especially with GMAW short circuiting transfer mode. W47 has NO PROHIBITION IN TEXT to stop you from feathering down that restart if necessary with a grinder, although many test conductors will argue that point. This is where most tests fail, on the restart areas at the root.

4. You say you are having problems with "the last inch" With short circuiting GMAW especially with beginners, this is usually caused by the welder turning their wrist to get the last couple of inches of the assembly and changing gun angle when they do it. The best way to avoid this is to set up your conditions as comfortably as possible and do a "dry run" before each pass, meaning; Take your position and move your gun/stinger along the entire length of the pass without welding to see where you might have to make a body adjustment in order to keep the correct gun/torch/stick angle while you proceed through the entire length.

5. Overhead welds are actually easier than vertical up welds..... How is that Lar??!?!?!? I'm so glad you asked. Weld metal is liquid eh? Think of a drop of liquid on the wall; what does it do? It slips down due to gravity yes? Now think of a drop of liquid on the ceiling; it stays in place until it get pretty big, it spreads out wide before it ever thinks about dripping off. This means that you can use a slightly higher current output (higher end of WPS range). quite often this will give you that extra fusion you need. The trick is to make your body comfortable for the entire length of the weld... Just remember, for the overhead weld physics are actually in your favor.

I hope this helps.... If it doesn't make sense or you are doing a different test... Tell us more about it.