First post here, hello Im a welder in Portugal at few years but i always welded with a gaz mig/mag.

But now i got an inverter 160a to do some stuff at home, never welded with stick rods and i need to weld galvanized mid-steel (going to use an angle grinder to remove the galvanized in weld spots before welding) with 1.5mm and 2.0mm (sorry about the mm)

Wich rod is the best? E6010, E6013?

And wich rod size? 2mm or 2.5mm?

Already asked in few stores about the rod E+numbers and they have no idea what im talking about, they seem to sort it by material and size only.

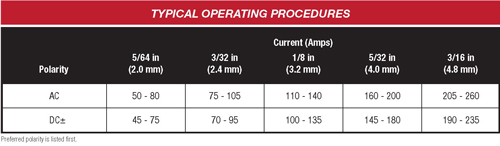

Btw im running around 40-50 amps.

The mid steel and the stick rod are 2mm (5/64 i think) and im using the e6013 in DCEP.

The angle im not sure whats the best for 6013 on flat surface, i already read 10-30 degrees but i also watched some youtube videos where ppl use them around 45 degrees

When welding a vertical joint it shoud go from top to bottom or from bottom to top?