Hello,

I would like to know by which way of welding progression would often increase the strength and reduce stress concentration and any other non desirable property on the corners of SS 304 pipe of 26mm thck which was cut in a rectangular shape.

Either, the longitudinal weld continuing to vertical uphill

Or, Completing with the longitudinal weld first and then the Vertical uphill[img]weld progression.JPG[/img]

By joedenly

Date

By joedenly

Date 03-28-2019 04:50

Edited 03-28-2019 22:41

How did you do that and how it's relates to stress, so far i ......(removed unusual link)- moderator

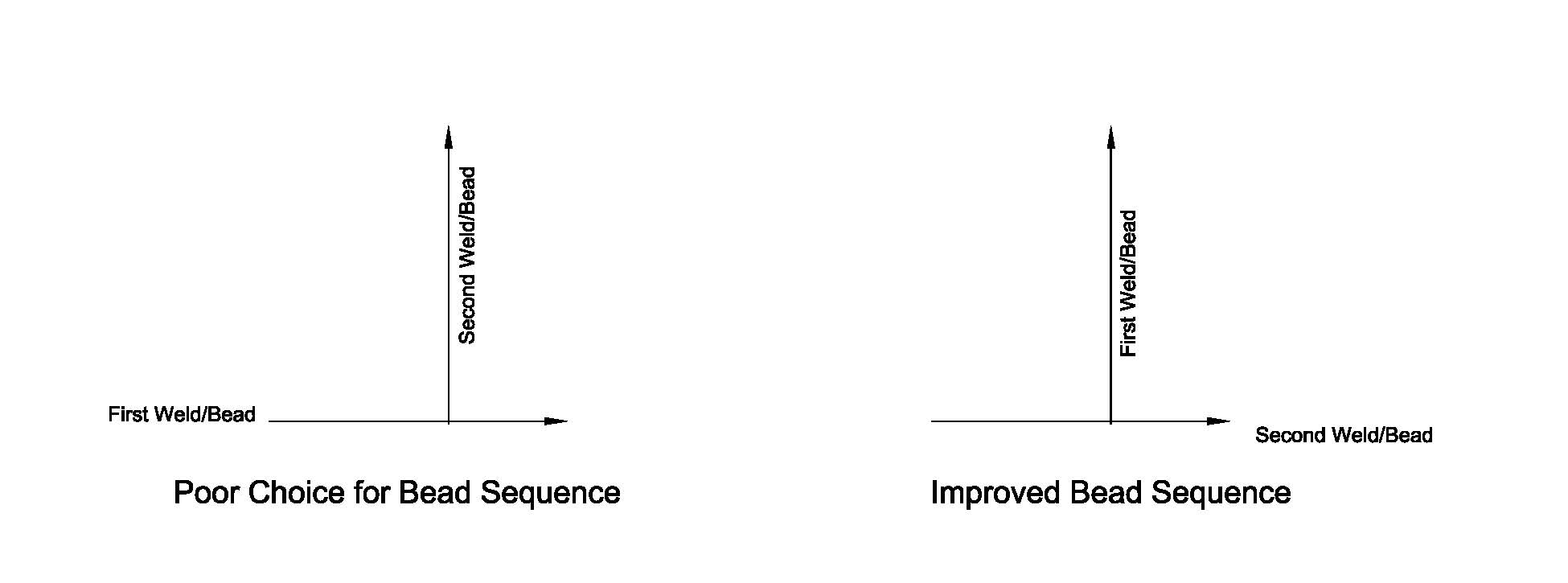

Generally, it is preferred to deposit the second weld such that the residual stress in the longitudinal direction relative to the length of the second weld places a tensile load on the first weld along the longitudinal axis of the first weld.

In the sketch labeled "Poor Choice", the residual stress of the second weld places a tensile load on the first weld in a direction transverse to the first weld. It tends to "pull" the first weld apart.

The sketch shows a second sequence such that the second weld places a tensile load on the first weld in the longitudinal direction which is more favorable.

Al