I'm not sure why I'm all of sudden hung up on this but...

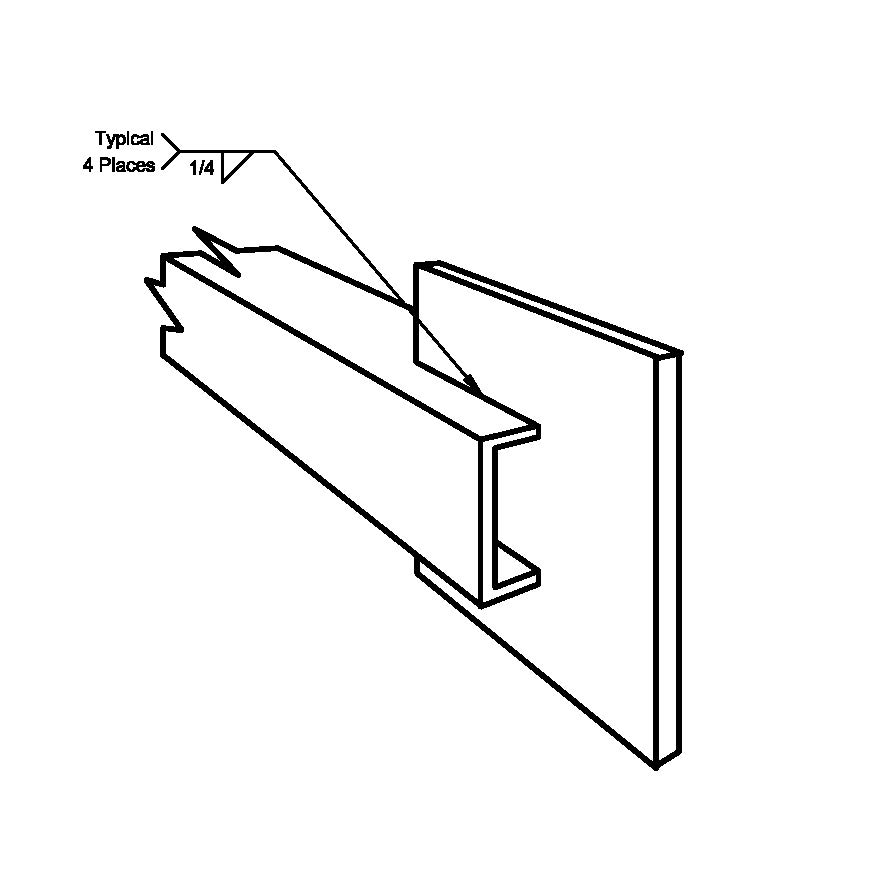

Field welding the HSS tubing to the gusset plate(fillet welds). Use Table 6.1 or Table 9.16?

Looking through Clause 9 where the main focus seems to be on T, Y, and K joints, I don't see how this fillet welded joint fits into this acceptance criteria other than the use of HSS sections for the bracing.