By seganti

Date

By seganti

Date 06-16-2008 04:05

Edited 06-17-2008 07:58

Whats up guys. Im new to this forum, my name is Jared Seagnti and Im starting a custom fabrication shop called SEGANTI METAL WORKS. 10 years of extensive experience since i was 17. Previous employers are: Kearny Mesa Welding, Metalcrafters, Revenge Racing, Predator Sand Cars, Alumicraft, Fusion Designs, Auto Sport Concepts, Asymtek, Currently employed at McCrometer. Through setting up shop, I have decided to turn my Linde ucc 305 into a hot rod. If anybody is interested in my shop, me, or my Hot Rod welder, DO respond. Talk to you later.

Jared,

Welcome to the forum. Sounds interesting. Post some pic's. I love Hot Rods, Hot Bikes, and Hot Wome.... never mind. Pic's of some racing frames would be cool.

jrw159

I'm very interested in your shop. Are you in the San Diego area?

Bob Garner from Sandy Eggo

Please tell me youd didn't put a spoiler on your hot rod welder? I like em low and slow for best of show, but all go and no show aint bad either. ;-) Lets see some pics!!

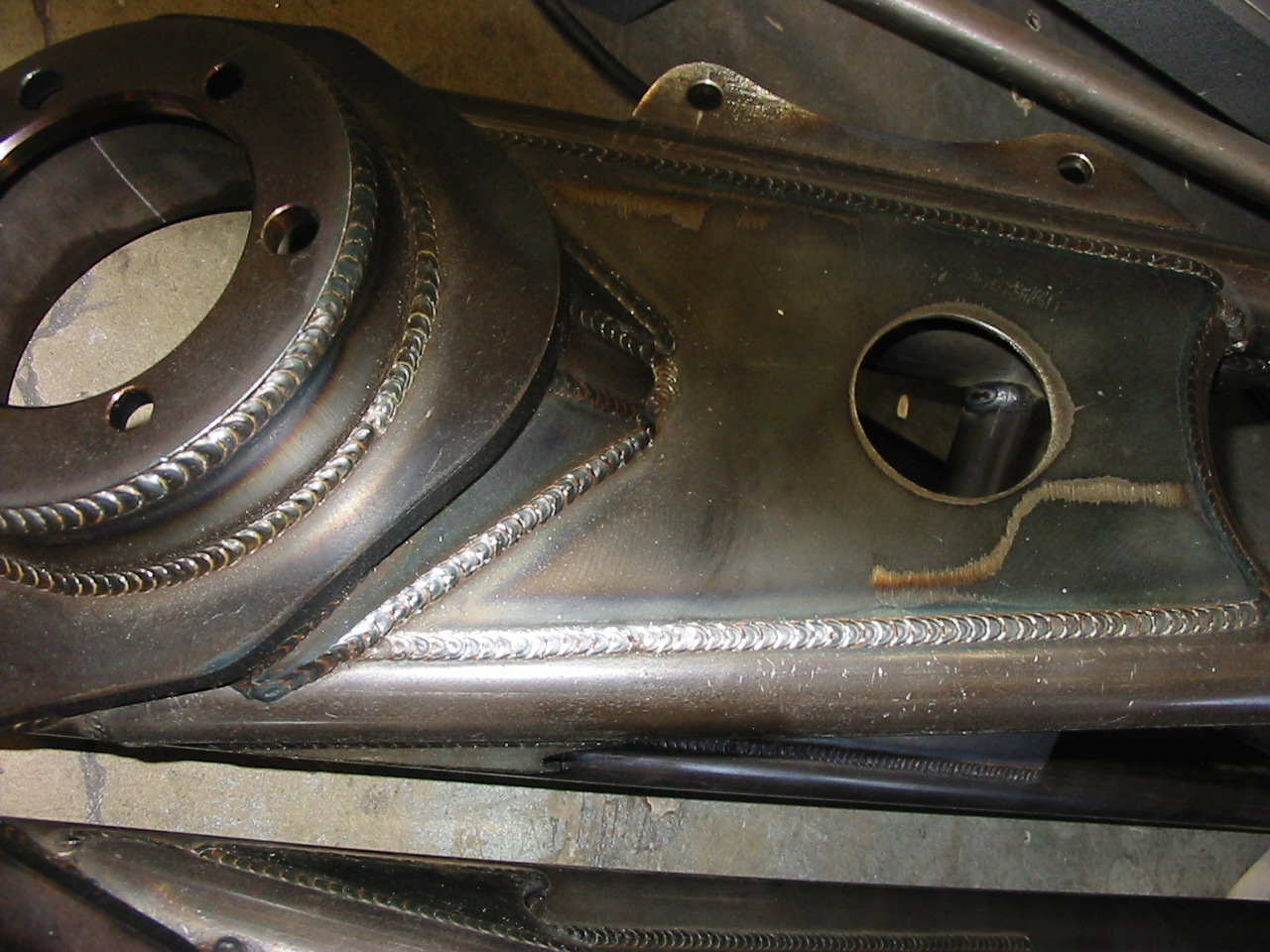

Sorry guys, been busy. Well, here are some pics of the old monster!(check original post) Still to come: some chrome, custom control panel decals, guage bank, and of course my polished stainless cooler. Also I have attached a TINY sample of my work and previous projects so you can get an idea. Oh, and yes, I am from S.D.. Currently in Hemet. Thanks for the responses, Enjoy

Man some of those parts must take a long time to mig weld using the trigger mode of transfer. I wonder if that could be put in the books as the 5th mode of metal transfer.;-) Stuff looks sweet man!! I'm out here in Wisconsin by all the race shops that fab up pre runners and desert race trucks for the baja 500 and such. I was in the shop that builds Jeremy Mcgraths pre runner not to long ago. Never thought I would see that stuff coming out of Wisconsin. Apparently that short course race series all started right up in Crandon Wisconsin out in BFE. I forgot the name of the teams I visited up there, but they did some real nice work like what your doing. They tig welded everything though. Have you ever heard of some rod called Jet rod for those chromoly tube chassis?

Yea we built a few short course CORR buggys at Alumicraft. I know CORR is huge in Crandon. Jet rod? Hmmm, never heard of it, we just used ER70s/ER80s rod. It worked very nicely with the moly, no cracks or breaks, I think it allowed for some flex which is nessesary for the rigors of off road abuse. Yea It is ultra time consuming to tig everything $$$$, i have done it a few times and it SUCKS. one word: preparation!

Nice stuff. The machine's a beaut. :-) Welcome! I repair & refurbish welding machines for a living myself. You are doing a real crack up job on your Linde. Please don't put flames on it! :-) I like mine all factory original. Good stuff. Stay active around here & you'll meet some really cool people. You already have. S.W.

"I'm a clown fish, and I know funny." (Marlin the Clown Fish, Finding Nemo)

Nice work, Jared!

Your shop is in Hemet? I gotta have you build a T-bucket for me.

Bob G.

Yea, good ol Hemet. I have everything minus: tube bender, lathe, and a mig(darn everything must be TIG welded for now). Let me know what youre thinking, sounds fun!

Thanks man. Well I hope "crack up job" is a good thing! no, no flames, clean satin black, clean lettering, a dash of chrome. you know like an old Merc. This is so cool because I thought i was the only person who loves shop equipment! Pics of your projects?

I meant that ENTIRELY in a GOOD way. You are doing a real nice job on it. Really! :-) Those whitewall tires on the back rock! Where did you get them? Or, did you do it yourself? Are you doing new lettering on the face? I noticed it's clean. I'm sure in the business you're in, getting custom decals or screen print won't be a problem. When you said Merc, I thought of the movie Cobra. That was a slick car Sly had! Here's a couple pics of some stuff I've done. I do mainly wire feeders. The D52D in the center pic was a complete re build. I welded & remachined the R. hand drive casting, it had a piece missing out of it. Turned out pretty good. Real nice work, Jared. Hard to find too many people doing machines. Everyone's into cars & bikes. :-) Steve.

Sweet! They look brand new! We have a D52D at work and believe me, you did a killer job. Those feeders are big bucks, you must be making some extra coin on the side...

Not too much. I do it full time & believe me, I'm not getting rich! Those D 52's bring about $850-900 on average. The 60 series bring the best money, but they are usually more to acquire as well. That dual head 60 was a real mess when I got it. Only saw $900 for it. Should have gotten $1200 or so. I have two very nice 60 series dual heads right now. Know anyone interested?? I take care of guys that give me a customer. If your boss ever wants to part with that D 52, let me know. Thanks!! S.W.

The pics below are what the D 64 looked like when I got it. Yuckky. :-)

Damn! What happened to that thing? I especially like the 3" grinding wheel washer! Ill keep my ears peeled for prospective buyers

HAHA. I wondered about the grinding wheel too! It was on a Deltaweld 450, in a shop in Florida that made high pressure air filtration units. I got the machine & feeder for about $400. Good deal, I acquired 4 other units along with it. Too bad the engine in my truck blew up on the way back to Michigan though! Thank God for warranties! S.W.

Hey, I hope I didn't hijack your thread. :-) This was about you, man. Got any other machines you have done?? Keep those pics coming!!! S.W.

Thanks for the props, Jared! :-) S.W.

Wow!!!!

Thanks again, John!! :-) S.W.