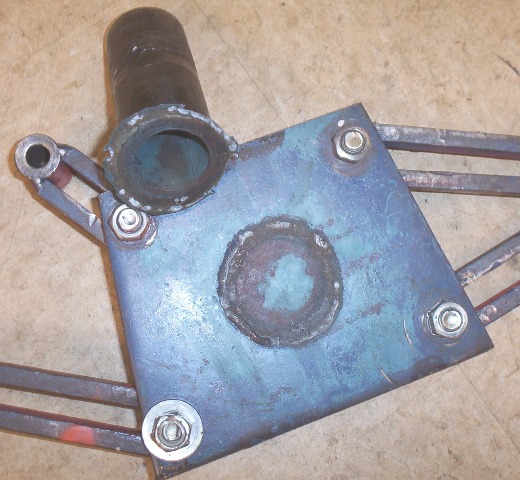

Hello Griff, I completely agree with your first two statements, regarding the latter one, the folks that designed and welded this weren't there to see it fail. When our students did the repair on this, the first thing they did was replace the "pipe" with heavy wall seamless tubing, the next thing they did was burn a hole through the plate, then they bevelled the end of the tube, ground a weld prep on the plate where the tube passed through it and then groove-welded the flush side and fillet welded the other side. As I mentioned before, once the welding was completed they die checked their welds to insure that they didn't have any spots where there wasn't complete fusion. Best regards, Allan