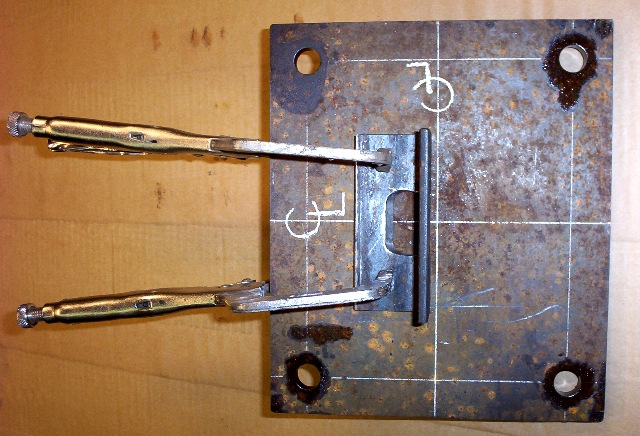

Allen, I probably couldn't explain this as good as you could. but I'm sure you'll see how it works. the bigger plate above the holes is the same width as the hole width dimension.

as you can see the drawing isn't to scale.

then you can use shims like you posted in your pics. although I originally made this for a system that didn't have shims, it had a slider rail so you could slide your piece across without the shims. More on that later.

this way every hole is coming from one corner. I think the biggest one I made was for a 9" hole spread for 12" wide plates. you can have 3 made up for 3", 6" and 9" hole spreads.

Its not the best thing to use, but when you only have an ironworker and have a few hundred plates to punch, it goes pretty fast.

Regards, Carl

Edit: the 3 small plates are what you have in your picture, for spacing multiple holes.