Hello everyone, I have some pictures to include with this and will post them tomorrow when I get back to my other computer and resources. Many of you may be familiar with this particular tool, especially if you do any machining to speak of. Simply put, this is a center-punch that is spring-loaded and once you have located the point that you would like to punch you apply pressure to the body and it will compress until it triggers the release and it leaves a "small" punch mark. Generally, as is the case with transfer punches, you will then use a regular center-punch and hammer to enlarge this punch mark to allow for further processing.

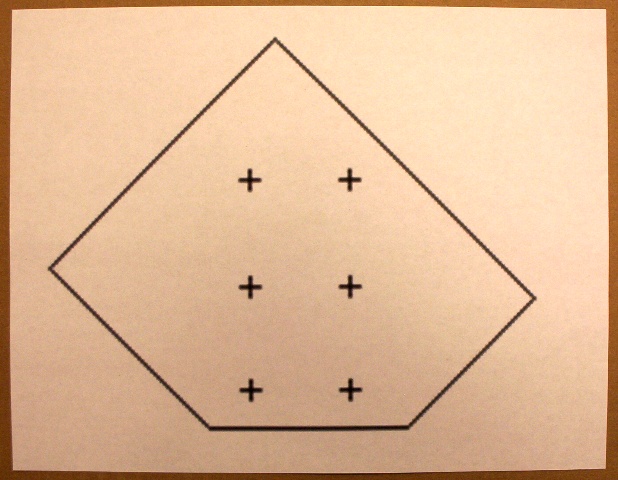

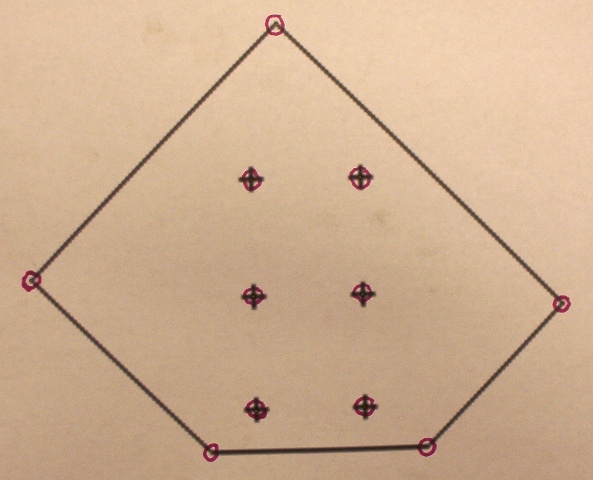

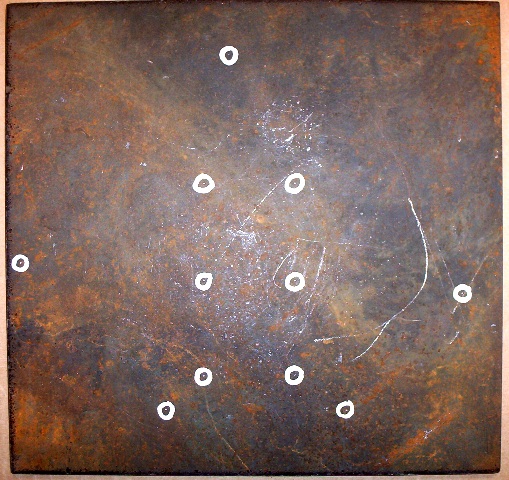

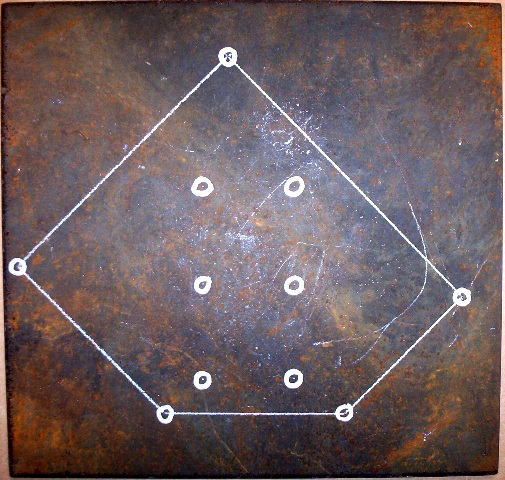

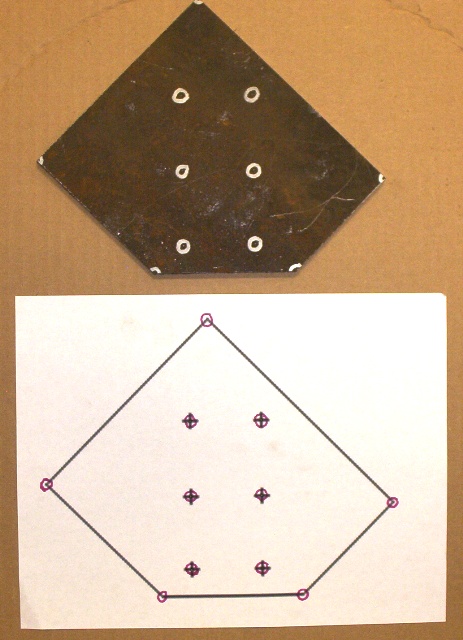

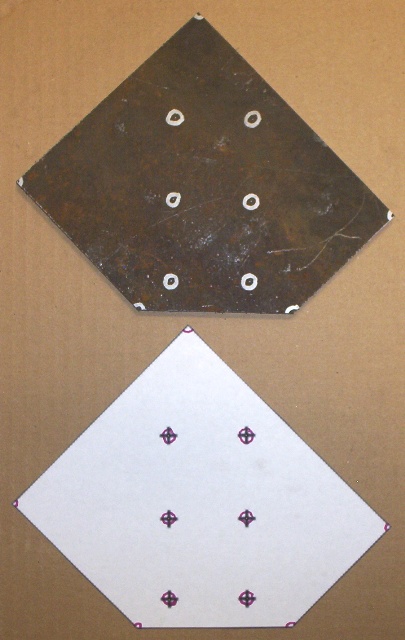

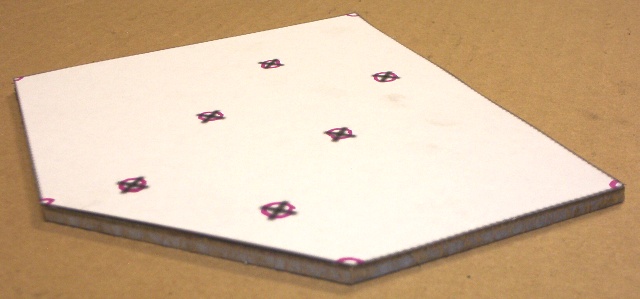

In many of today's fabrication facilities there are a large number of drawings that are generated with various CAD programs. In many instances these drawings will detail connection plates and other complicated shapes that can then be exported to burn tables, plasma tables, laser tables, and water-jet tables for processing. Generally the water-jet, laser, and some of the plasma tables have enough accuracy and ability to put holes in these parts and not require secondary processes to provide the holes. In cases where they may not, for whatever reason, the programmers will often times include hole locations on these drawings. The drawings can be reproduced to scale and printed on paper to be used for patterns to locate and mark these hole locations by laying these scale patterns ontop of the parts and the automatic center-punch can easily be employed to mark these holes.

For those who may not have ready access to these CNC type material processing systems there are some other possibilities: one is to print the pattern on paper and use a burn/plasma table that is equipped with a Linatrol or similar line-following eye system and then cut these shapes. Or simpler yet, produce the patterns with paper and depending on whether they can be sheared out or cut out with a hand torch/plasma proceed to cut them out. In the case of straight cut shapes that don't have inside corners you could use the automatic center-punch to locate the corners and lay-out the holes and then connect the dots so to speak and either shear or burn on these lines and then punch/drill the holes.

Once I have included the pictures that I have for this topic, I believe it will make a lot more sense. As Mark mentioned about the transfer-punch thread, you do need to be sure that the pattern stays in place while you are doing any tracing or hole marking. The nice thing about using an automatic center-punch over using a conventional center-punch and hammer is that the impact remains constant and it doesn't tend to over-size the hole in your pattern and thus cause inaccuracies. Generally the divot produced with the automatic is such that it allows you to see where the point is easily enough and then you can upsize it according to the purpose that you have in mind for it. Since the automatic is a one-handed tool you can hold the pattern in place in many cases and it doesn't necessarily require clamps or other holding aides. I'll include the pics tomorrow. Best regards everyone, Allan

Actually, there is another use for an automatic center punch that is "a bit different" than what you describe here. A very expierienced field welder showed me this trick and it gave me a "V-8" moment once he showed me.

Use the automatic center punch to fracture and remove weld slag from hard to reach areas. It is slick for cleaning the ends of fillets, in tight places, and many places that you can't get a slag hammer or chisel into.

Hello Chet, thanks for replying, hadn't thought of that one, but could certainly see the possibilities and advantages to using that "trick". Thanks for the reply and best regards, Allan

they will also smash a window out of a car pretty good too I think they say something about that if the car is submerged in water they will break the car window so you can get out or was it something about using it in the bar parking lot, on the car window, of the guy that spent the whole night hittin on your girlfriend????? Of course I wouldn't know anything about that......LOL....

Just my luck....the last time I was trapped underwateri n my car , I left my automatic center punch in my other pants pocket.

Joking aside, that's not a bad idea and you can buy the General version for not a lot of money. I think Home Depot carries them.

I started keeping one in my car ever since I got a car with electric windows.

Ahhh, yes. The automatic center punch. We would use them to mark air holes in aluminum molds when I worked at Dart. We had to lay out the molds with a small ruler & instead of marking, then drilling, we would just set the punch to a very light pressure & punch it at the correct mark. Worked really nice for very small holes.

S.W.