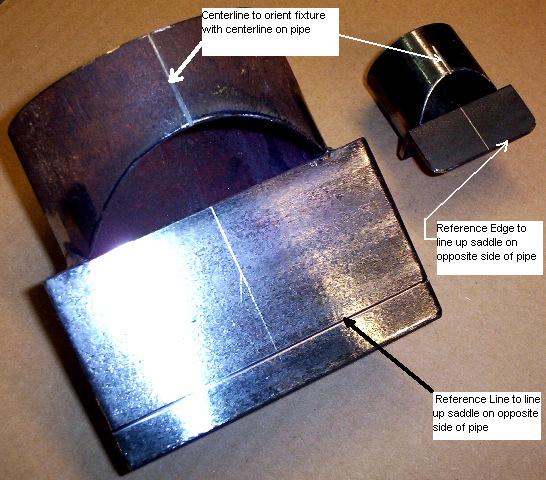

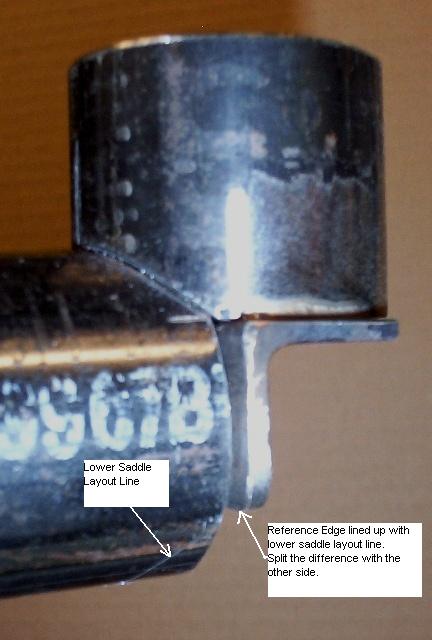

Hello everyone, I imagine many of you do a fair amount of layout and cutting to fit saddles for various pipe applications. Anything from handrail applications to barrier fencing to protect gas meters and other sorts of things. If you are involved in doing this in the field and considering having an aid that will take a fair amount of abuse as well as being able to use a scribe to scratch your cutting lines and then finish grind to the line, these little units might be the ticket. I have two examples that I have included photos of, one is for 1 1/2" pipe and the other is for somewhat larger pipe. By using the example that I have shown you can make additional units of whatever diameter you might need. The nice thing about these is that you can use just about any sort of marking tool to draw your lines and not damage the layout aide. I used a thin-blade grinding wheel to mark the centerlines on these and also the reference line on the larger one. Sorry for the picture clarity on a couple of these and hope you can see how these can be used. Best regards, Allan

HI SR, I don't no were you where 2 weeks ago, with this gig you will saved me alot of time, I just finish a 100' of 3 orizontal rows of 1 1/2" dia. pipe "horse corral" for a farm in Chino Hill, Ca. but I goin to make some of thos gig's for 1, 1 1/2, and 2 in dia. pipe for the future. Thank you very much. I'm Jaime.

Hello Jaime, when I used to work out in the trades a lot more than I do now, I had a couple of different sizes of these, they really helped with the times when I didn't have a pipe-notcher around. Hope they will serve you as well. Best regards, Allan

very nice, would you mind if I printed the pictures out for some of the lads?

Charles Welch

Hello Charles, please feel free to do so and if you have found any of your old aids or other short-cuts, tricks, please include them on here as well. Best regards, Allan

right niffty idea you got there Allan puts my yellow metal hinged stensils to shame there just aint sumthing right about them i cut inside the line and always have to fill a gap at the bottom even try cutting the tips off and still have the gap heck if i know

I had an old pipeline welder tell/teach me to cut the line on the points and leave the line in the throat area. It's always worked well for me. Chris

Hello Shad, I have certainly eye-balled plenty of these over my career and have welded up plenty of gaps as a result. Whoever it was that said "work smarter not harder" certainly has my vote. I try to keep that in mind as I go about my daily business and "do" try to keep my eyes and ears open, as well as my mind, concerning any short-cuts or time savers. Have a great day. Best regards, Allan

That's one slick little tool. Never seen anything like it. I don't do much round work because of the labor involved.

I only usually will do it only if I can cope it on my mill with a rougher. This is quick & easy method, taking the guess work out of eyeballing & cutting freehand. They would stow away in a tool box right on your job truck.

Great idea! Thanks! S.W.

I use a contour marker, or as we call it a grasshopper, can be used to layout angles on beams,angle,tubing or pipe. Just set to 361/2 degrees. will work up to 18" pipe. when doing handrails use this with a portaband, no grinding, no heat, no gap. weld with 1 pass 3/32 7018, file and polish. also works great for layout on 12" branch

Pard that jig is the bomb!!!!!!!! My joints have never looked better keep the tips comming.

Hello OxbowCS, glad you liked it. If you haven't already, go back through the various topics in the "Tricks of the Trade" there are likely a number of different contributions from a host of others that you can put to work for yourself at some point. Best regards, Allan

Hello hojopens3, thanks for replying and including the information on the contour marker. I have used 2 different units such as the one you are referring to, Curvo-mark and Wizard, there are likely a host of others that work similarly. If I get a little more time I will try to include some pictures of these units and also include something on the use of the porta-band. I am glad you mentioned the porta-band, have done a fair amount of thin-walled piping and the porta-band can be a real time-saver and also save immensely on grinding when you are dealing with these situations. If you have any pictures or ways to come up with some, I'm sure that myself and others would appreciate seeing them. Thanks again and best regards, Allan

hello aevald, the one i use is by curve-o-mark, i'll try to get somepics when i go back out, i work in the gulf of mexico, 14 on 14 off

Hello hojopens3, will look forward to those pics. I imagine with your schedule things get to hoppin sometimes. Best regards, Allan

Aevald. Pretty slick. They make coping tools that you can pick up at airgas, if you dont want to go this route.

Hello sourdough, are those tools similar to the Curve-o-marks or the Wizards, or are they something else? Thanks for replying and best regards, Allan

The cope is double sided, and the tool opens on hinges like a clamshell then close around the pipe. They also have openings for finding a 45*. There's all kinds of sizes. Not sure what brand mine are. I keep one for 2", and the other is 1 7/8"

Hello sourdough, no, I haven't seen those, I'll have to try and find some of them and check them out. Thanks for the heads-up. Best regards, Allan

How's work in your neck of the woods. Very slow here. I've resorted to putting the ol '77' 10 yard dump to work and the backhoe. Hauling gravel and digging ditches just aint welding, if you know what I mean. Scary stuff. You like to hope that you can squeeze a few more years out of a boom town, but it just don't work that way. Hopefully a guy is smart enough to pay everything off, and not buy a half million dollar home that isnt worth 150 grand. We didn't do that, but a lot of people did here in the rockies. People are walking away from their homes left and right because they cant afford them anymore. Lay-offs are rampant. We'll see. I may migrate south to the big state, you never know......................

Spose this post belongs somewhere else. Maybe the adminstrative gurus can do that for me...........

Hello sourdough, in my immediate area things have slowed a bit and we've also had some major industries downsize or fold-up, not good for our local economy. Plenty of folks looking for work and also facing re-training, good for my job in a sense, but not good for everyone else. To the north of me in the area surrounding Seattle I believe there is still quite a bit going on. To the south of me in the Portland area a similar type of situation, I believe there is still plenty to keep a lot of folks working. In most all of these instances the jobs are probably shop related and not bringing in the bigger money from construction type work. So, that's the short rundown for what's happening around here. Keep your head above water and keep pluggin along. Best regards, Allan

I think that this is what sourdough is talking about. one is a 2 3/8, one is a 2 7/8 and the last is for 4 1/2. the last one has a mark for 45*, 22 1/2*, 0 and the saddle. they work really well and I use mine quite a bit.

Hello stkwldr, thanks for including those pics, looks like a pretty decent addition to a toolbox as well. Best regards, Allan

Thank you for including that John. Regards, Allan