Allan,

THANK YOU! You have finally put to picture something that I have been getting bashed on for years now.

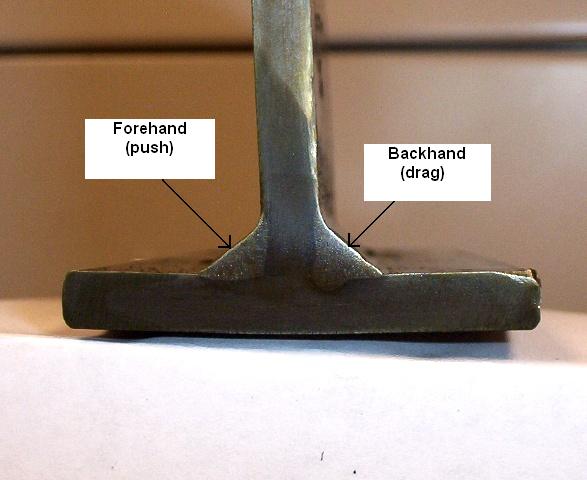

One shop I worked at was all GMAW; .035 70s3 (it might have been s6), 75/25 Ar/co2 gas, and the voltages and wfs varied a lot because of the thicknesses (1/16 up to 3/8) and positions, but I was labeled a "drag queen" because everyone else pushed "because it penetrates better". The WPS's (if you could call them that...) left the subject wide open other than the 30* limit.

The shop closed not too long ago, so even though it doesn't matter anymore I still feel better, Thank you again :)

Just out of curiosity, when you say Tri Mix do you mean a mostly helium, argon, O2/CO2 mix?

Thanks again,

Clif

Hello Clif, we use gases supplied from Airgas. I don't know the exact mix of this particular one, however, I believe it is mostly argon, secondly CO2, and thirdly helium. My latest specification sheet from them lists three generic tri-mixes. I believe you can also request special mixes, for a price. Enjoy your weekend and best regards, Allan