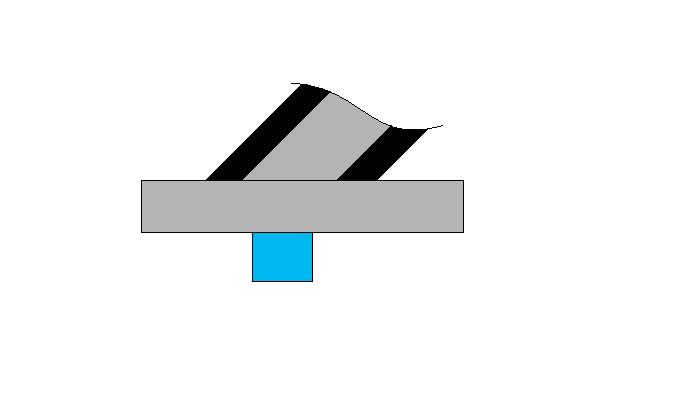

Yes. That shear lug is as long as the base plate is wide...(in your view, going in/out of the computer screen)

I've never had one that was as wide as the base plate, usually they are much shorter.

I just want to verify these welds because either an Engineer is very concerned about the loading or has way over-engineered this thing.

The pipe column has a 5/16" fillet weld to the base plate, yet this hug shear lug is full pen to the base plate. In my simplton mind, I see the pipe shearing away from the baseplate long before anything happens to that shear lug that will be grouted into the concrete.