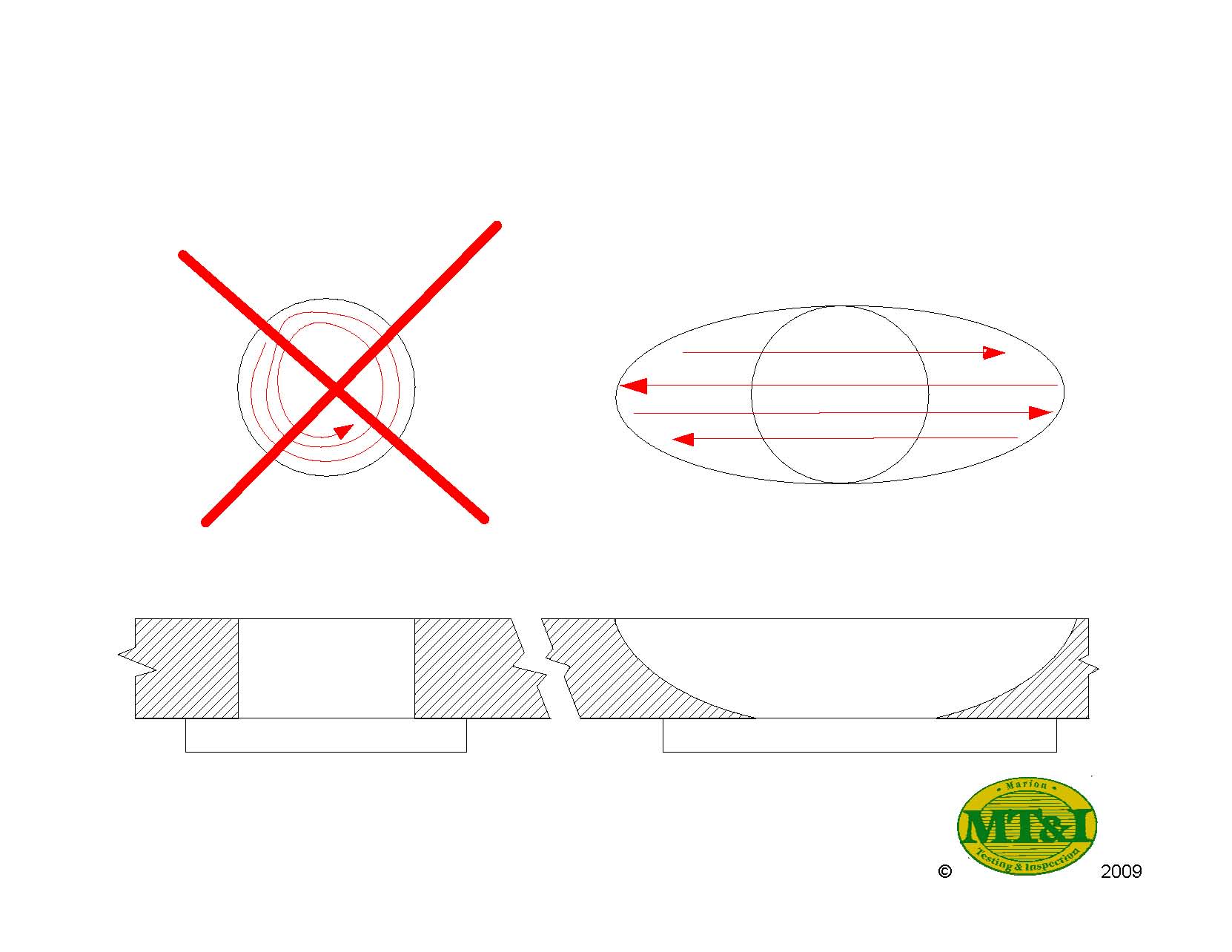

The typical method of repairing mislocated holes can create more problems than it solves. Most welders place backing under the hole and weld in a spiral, starting from the outer corner spiraling in toward the center of the hole. Depending on the process there may be slag to contend with. In any event, the residual stresses are high and it isn't uncommon to see cracks when sufficient ductility isn't a characteristic of the base metal. The higher the strength of the base metal, the more likely cracking will be a problem. The other problem is the opportunity to have incomplete fusion along the outer corner (inside circumference of the hole). That problem can be addressed when the backing is removed. However, the cracking can be very tight and difficult to see without MT or PT.

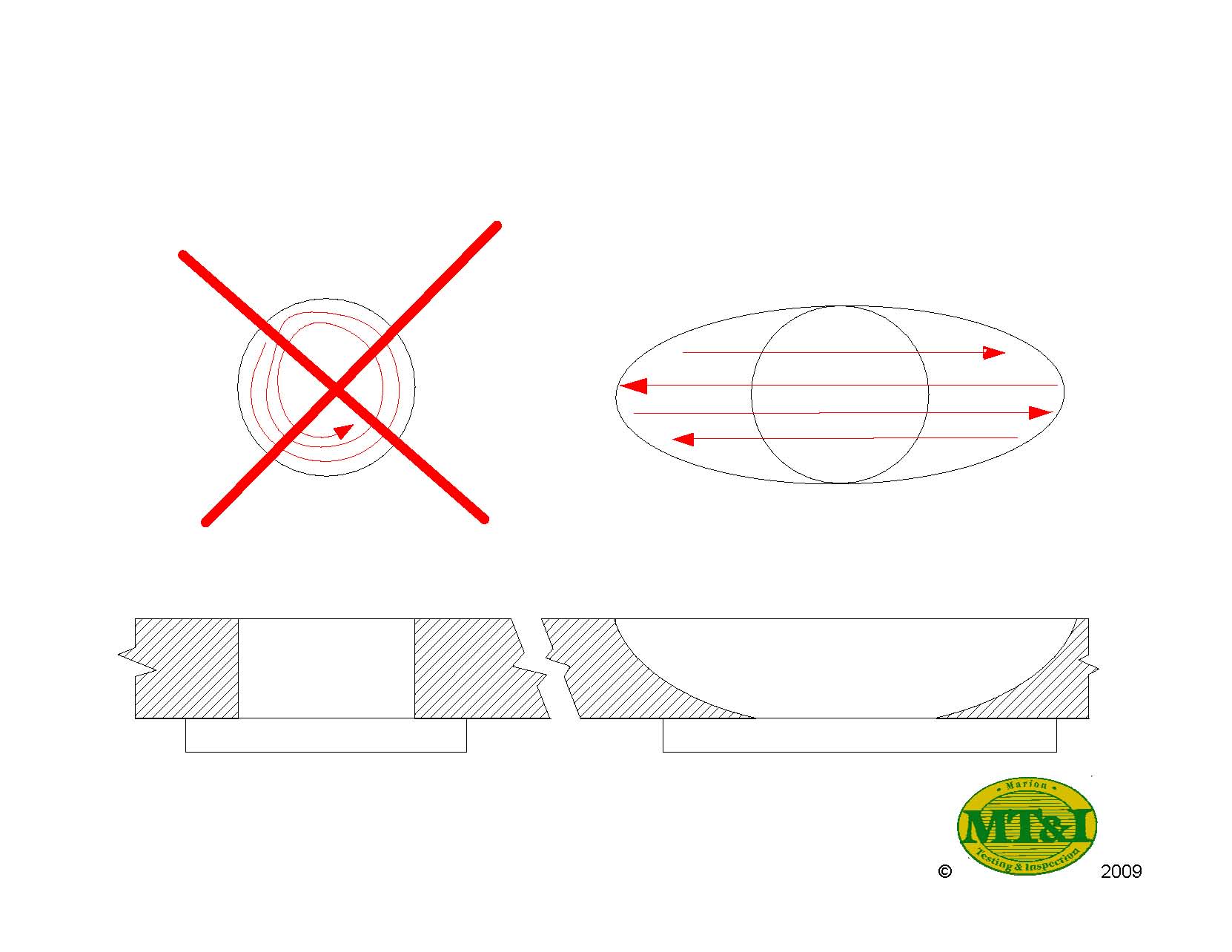

I have had good success by elongating the mislocated hole with a grinder so the hole looks almost like a canoe. The hole is still round at the bottom where it is backed by similar base metal, but the top of the "groove" is elliptical; the length being on the order of three times the hole diameter and the width of course being equal to the hole diameter. The groove is then welded using stringer beads so each bead can be easily chipped to remove slag, oxides, etc. I've never had a cracking problem with this technique and they've always passed UT and RT.

I always look very closely at the site where mislocated holes have been repaired by welding. The use of copper backing, improper or incomplete cleaning between passes, poor access resulting in improper electrode angle, etc., all contribute to the problems I see with typical repair technique used to correct mislocated holes.

Best regards - Al