Well after making a bazillion jigs to make cutting this stuff out easier, cut out 8 18" sections in about 10-15 minutes, both with 22.5 on each end. I finally got the sucker together, of course I had to build a jig or a tubing notcher so I could notch the tube for the pedestal legs on each end. Did not want to spend $80 on a fancy store bought so I spent $8 on two exhaust clamps and used some of the hoards of steel around the shop. One new hole saw and wa-la, tubing notcher. Worked frickin' AWESOME!!!

Anyhow, here are some pics of the finished, well almost finished. Still have to get the exterior coating on it. Gonna go see a guy about that tuesday and see what it's gonna cost. He could not give me a good number and wanted to see the finished product to give a firm price, or just shoot it and experiment to find out how long it's gonna take. I gotta say this was a wicked cool project. The math involved the angles, figuring all that stuff out was a great work-out for the ol' brain.

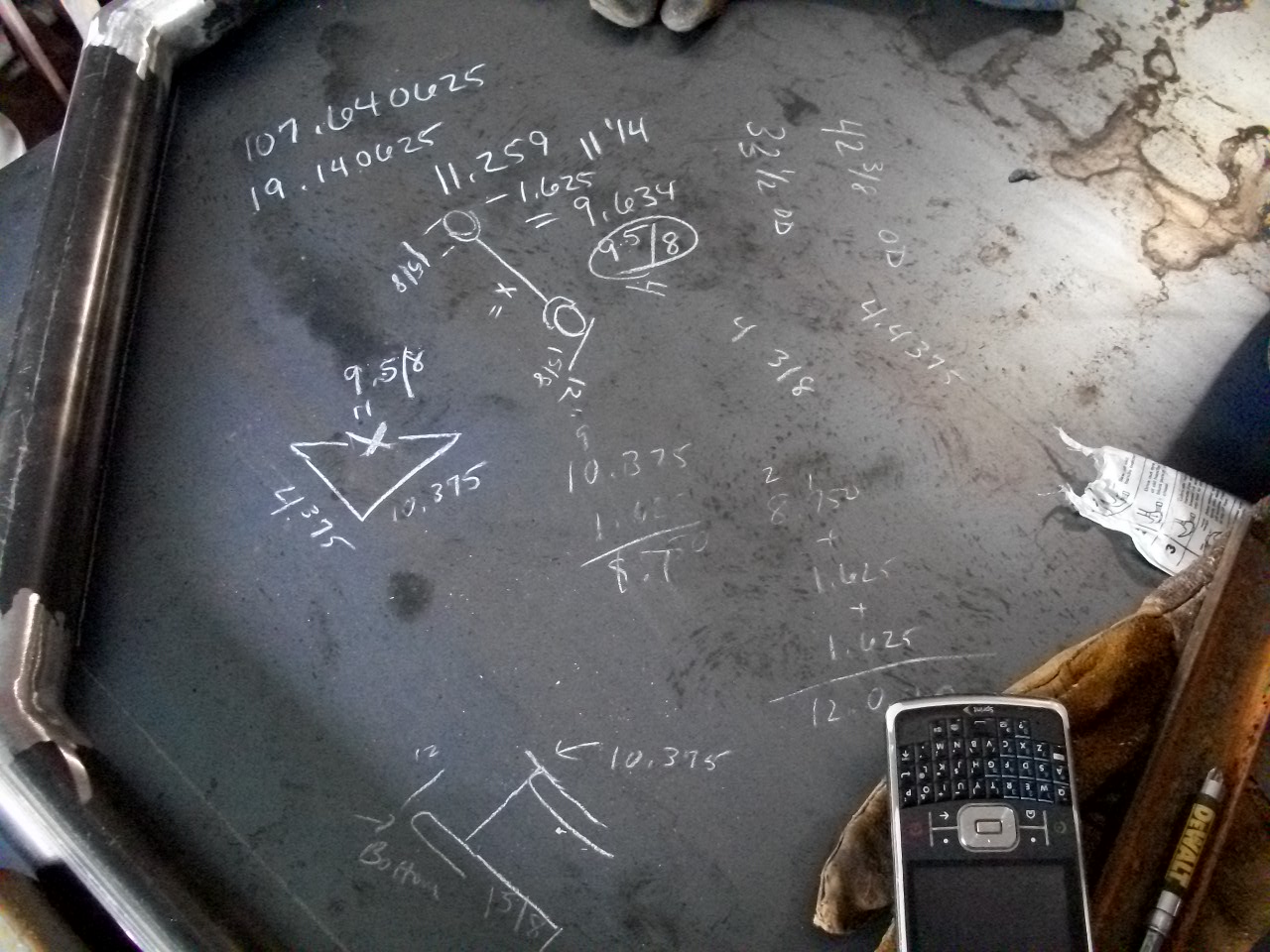

The first pic is of it all welded up. The second is my chalk board, my wife said it made her think of a college chalk board, it makes me laugh cause I can't believe I can keep all of that straight all scribbled all over the place!! The third is during the build up, had to grind off some of the notched ends to get the fit right. I wanted it 12" off the ground and once everything was welded up and measured I think I'm about 1/16th off.