I've got some good Cuban recipes in the OTB&G for you to try for "Lunch" Al!!! :) :) :)

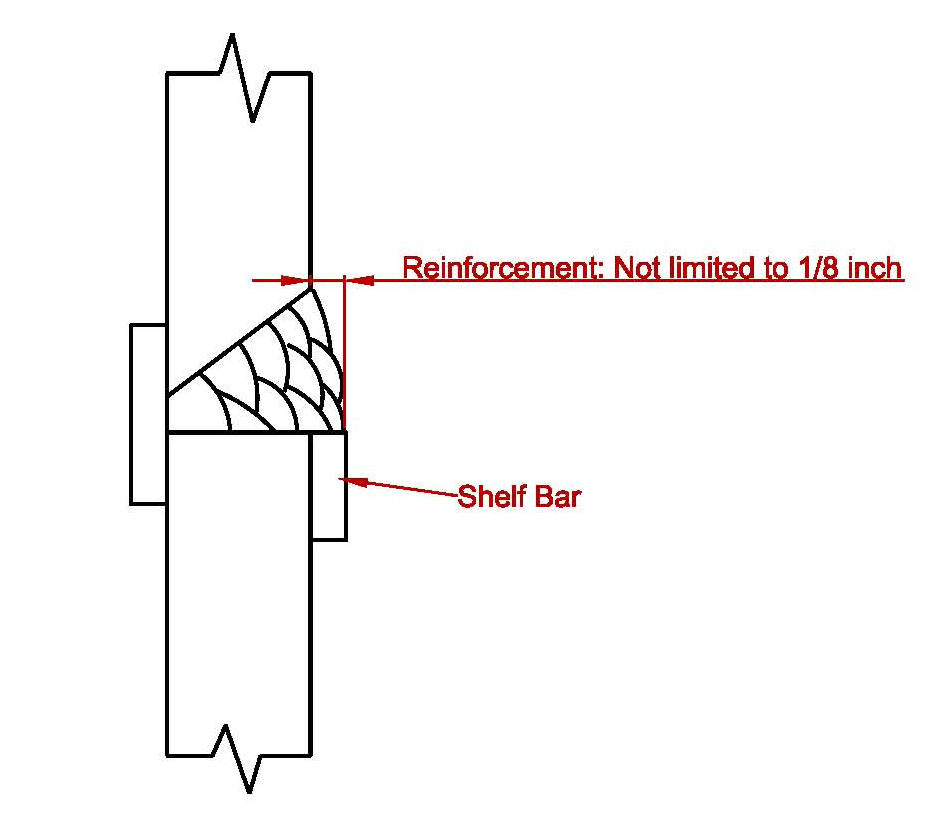

Seriously though, I would think that if one was to use larger diameter wires in order to increase the deposition rates with self shielded FCAW on columns, the use of a shelf bar would more than likely be advantageous in that respect as well as helping the welder to start a decent cover pass as long as the use of these are not to be incorporated at locations where there would be enough seismic activity whereby these columns would no longer be subjected to only static loads exclusively... If potential seismic conditions are present within the are of construction, then a different system would need to be used instead. ;)

Btw, the Cuban Sandwich is an easy one to make, and the "Ropa Vieja" ("Old Clothes!") is really good Al!!! :) :) :)

Respectfully,

Henry