Chris,

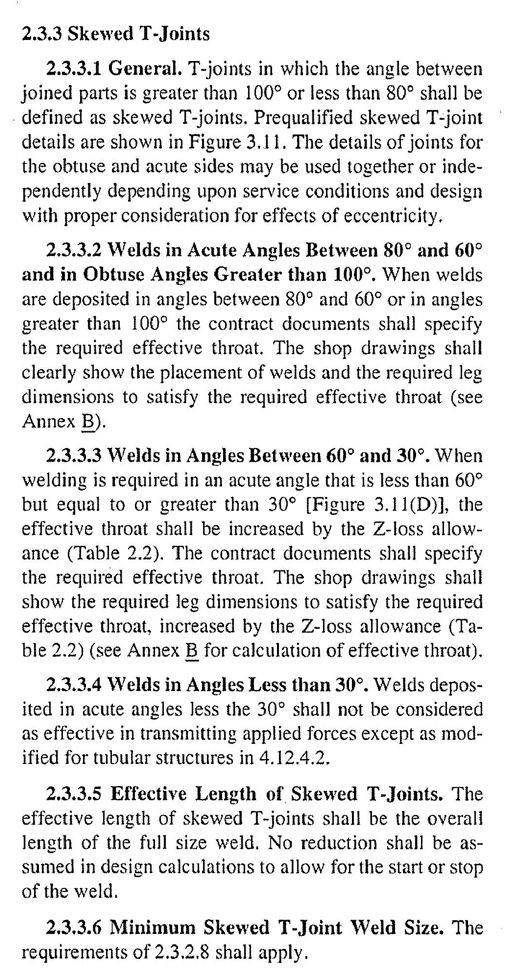

The AISC 13th edition of the Construction Manual addresses this condition(skewed shear tabs in the webs of beams)....several ways to approach the weld call out depending on the situation.

See AISC manual Table 10-13, pages 10-164(for 5/16" and 3/8" thick plate) and 10-165(1/2" plate)

Also see Figure 10-38 on page 10-151

note the skewed connections and that they use a fillet weld symbol on all but one, and they call it out as a BTC-P4 modified. Also note that some use the square edge of the skewed plate and others use a prepared edge on the skewed plate; where the plate meets the web.