Hi Marshall!

It was a "loaded' question...

You are correct in using the letter "K" when spelling out the name of the person (

Ish Kabibble (January 19, 1908 – June 5, 1994) was a comedian and cornet player. Born Merwyn Bogue in North East, Pennsylvania, his family returned to Erie, Pennsylvania a few months after his birth.) who "coined" the term from an older song derived from a mock-Yiddish expression, "Ische ga bibble?", which was purported to mean "I should worry?", prompting a curious (and perhaps not coincidental) association of the comedian with the "What, me worry?" motto of Mad's mascot, Alfred E. Neuman.

While this derivation has been widely quoted on the Internet and elsewhere, the expression

"ische ga bibble" is not Yiddish and contains no Yiddish words at all.[2] However, there is a Yiddish expression,

"nisht gefidlt," meaning "it doesn't matter to me," from which the term

"ish kabibble" may derive.

My spelling of the slang term only personifies the meaning of the word by not worrying about how it's spelled, or it's usage. ;)

Influence:

Kabibble's distinctive black hair in a bowl cut, similar to that used by Three Stooges member Moe Howard, is said to have been an inspiration for the hairstyle worn by Jim Carrey's character in Dumb and Dumber. Some maintain that Jerry Lewis lifted his comedic persona and look from Ish Kabibble, making an otherwise identical character more manic than Ish Kabibble's earlier presentation.

The name "Ish Kabbible" was used for a hoax student supposedly enrolled at Princeton University in the 1950s.

In 1985, the character's name was used as a plot device on the animated series The Thirteen Ghosts of Scooby-Doo. On this series, Scooby and the gang, along with an animated spoof of Vincent Price, are in search of the Amulet of Ish Kabibble.

In the TV show M.A.S.H., Alan Alda's character "Hawkeye Pierce" several times refers to Ish Kabibble. Once he asks who he and Trapper John should drink to - MacArthur or Ish Kabibble? Another time he refers to Ish Kabibble and his All Girl Orchestra and refers to him as part of a dream.

In the TV show Green Acres, Sam Drucker sells "Ish Kabibble" kazoos.

All in the Family: In the "Cousin Maude's Visit" episode, Maude refers to how the name "Ish Kabibble" used to make Archie Bunker laugh. ;)

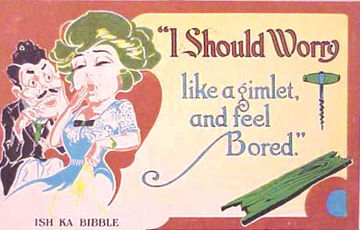

The origin of Merwyn Bogue's stage name, Ish Kabibble, can be traced back to the 1913 novelty song "Isch ga-bibble" and this 1915 cartoon postcard, which displays a spelling (Ish Ka Bibble) almost identical to that used by Bogue. Between the song and the card, in 1914, Harry Hershfield introduced his character Abie Kabibble in his comic strip Abie the Agent.

http://en.wikipedia.org/wiki/Ish_KabibbleRespectfully,

Henry