any groove symbol (xcept flares) without sizing indicates cjp, I get fabricators telling me, "that's a partial..." my answer "how much of a partial"

How much of a partial is pretty evident. If it can't be reached from the back side for backing, back weld, or back gouge, by definition, its a full thickness partial pen. It all comes down to its application, and one quick phone call or email could settle all this speculation that has been posted here. It could also be meant to be used as a seal weld. Column caps are not a structural weld and can be shown as either a fillet with a weld size or as a square groove/seal weld. Deck plate butt welds on some types of skid floors are also shown simply as square groove welds, and some where on the page there may be an obscure note making reference to depth of penetration. The original post asked simply for an interpratation of the symbol, so, you can only read whats there.

Just from my personal experience, Platinumbased,

The current trend is to make as many of the weld joints fall under the 'Pre-qualified' class as possible. Keep it simple and straightforward for the fabricator, erector, and inspector.

A weld called out as one sided with melt through is not pre-qualified.

A CJP with backing, backgouge, etc is pre-qualified.

Now, your actual question, yes, using the melt through symbol would drive a final nail in the coffin as to the engineer expecting the joint to be welded from only one side with melt through to establish CJP completeness. But the contractor would need a tested procedure and WPS with welders qualified to complete that weld in order to do it that way. Not a prequalified joint/weld.

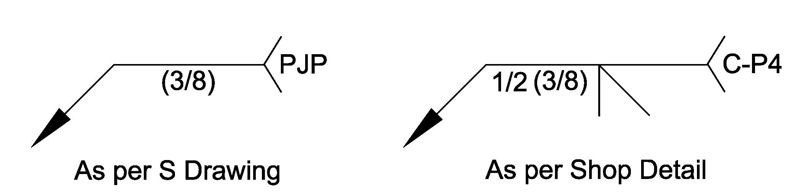

As previously stated by myself, Marshall, MB, and others, according to A2.4 and D1.1 there are several symbols that establish the joint as CJP when there are no measurements included in the welding symbol. It can also be done by calling out a CJP in the tail and not giving any joint configuration.

In the case of the current OP's question, the joint is called out, just no measurements. I still maintain that that dictates, BY D1.1 CODE, a CJP weld. A prudent fabricator would more than likely submit an RFI requesting clarification and authorization to weld it from both sides IF POSSIBLE in the joint in question. This should be handled when in the detail process to submit shop drawings before the work has actually begun. The bottom line is that there is a CJP weld that the contractor needs to bid as such and know the inspections will also be different that other joints.

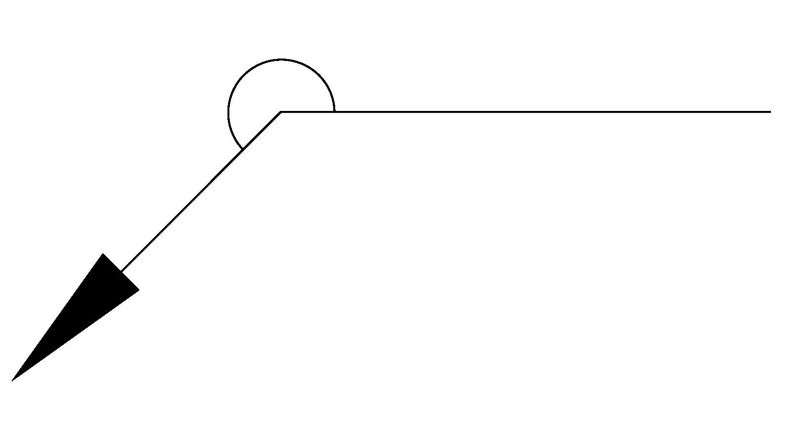

Some may well be correct, laziness on the part of an engineer, not the most efficient way to deal with it, etc. BUT, there is much we don't KNOW and are only speculating upon as to the APPLICATION of this symbol. The OP only wanted to know it's meaning. To me the meaning is clear. There is no confusion. It is a CJP weld in a butt joint welded only from one side. Bid it as such and you can't go wrong. Get an RFI if in doubt as to the actual application in order to accomplish the job especially after seeing how the joint is actually fit up and what type of accessibility there is to the joint.

Have a Great Day, Brent