Back to your original question, that is, whether the joint configuration is a butt joint or a t-joint?

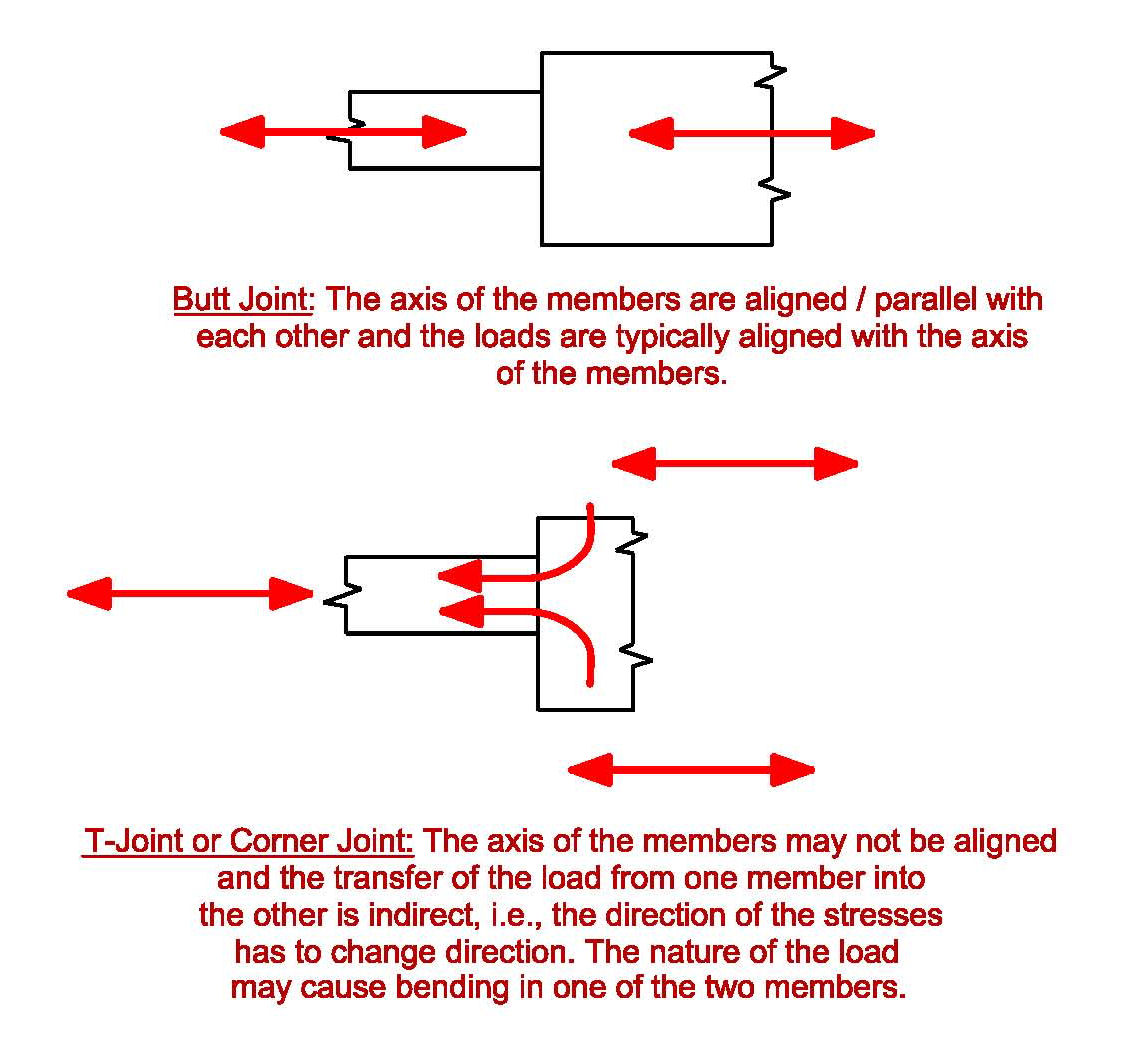

You need to look at how the load is transferred from one member to another. If the load is either in compression or in tension, the butt joint, where the axis of the members are parallel, does not require the direction of the load to change as it transfers from one member to the other. On the other hand, the T-joint or the corner joint, where the axis of the members are approximately perpendicular to each other, requires the direction of the load to change as it is transferred from one member to the other. The change in direction usually causes bending or a prying action.

The sketch depicts what I mean by a change in direction of the applied stress. I did not address shear loads where the loads are transferred a little differently.

Best regards - Al