Weldwade posted that link and that is a good one for finding out what a bunch of us are using. As far as stair layout goes, well, go to one of the home stores and pick up a carpenters book for that, I've seen a few and my brother in law the carpenter has a good one that shows the basics. The thing I hear most from people is very few know how to layout stringers and stairs properly. May have something to do with the trigonometry involved, doing the math so your steps are all within 1/4" of each other on the rise and so on. From what I've seen around here the 1/4" +/- is only true for steel guys. Concrete/wood steps are all over the board, 5" on this step, 7" inches on the next step, 6-3/4" here, 6-1/4" there. Not to mention stringer length, cut length, then throw in setting steps 2" below top of stringer, setting stringers level and square to each other, figuring the pitch of the slab the stringers will rest on, how much fall between left and right and how that will affect your steps. You can get basics from the book but there is a lot to learn, things you have to figure out when building stairs. Once you figure it out and do many of them, it's pretty fun.

Do a google search for stringer layout or go to home store, then get a notebook and label it "Stair Layout" and write down all the things you learn that the book you bought does not tell you about, and believe me it will leave a lot out. This way when your 6 months to a year between building stairs you can reference your notes and refresh your memory on the things that made it easier, quicker or correct.

Shawn

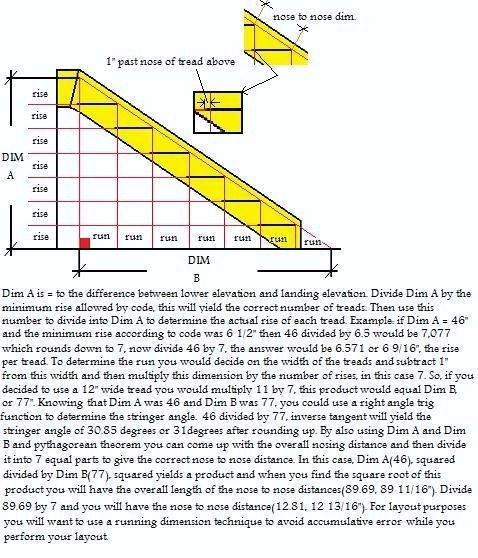

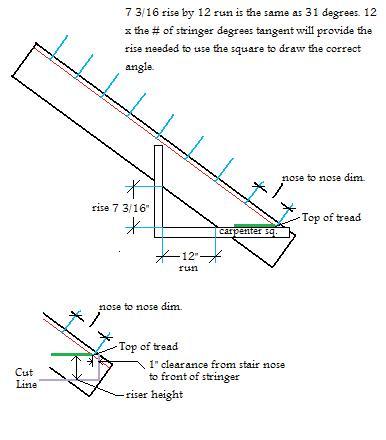

Hello Shawn, here's a little something to think about for stairs. I have done quite a few over my career and have always tried to pay attention to easier, more efficient, and accurate methods. I also keep thinking that I will be able to compile directions to explain these methods, haven't quite gotten to that point. Here is a schematic that does discuss/illustrate a bit with regard to stairs. Stair codes vary all over the place from state to state and with regard to industrial, public, and private applications, those variances certainly do complicate stair construction. One of these days I might actually complete my thoughts and views on stairs and hopefully present them in an understandable manner. Best regards, Allan

aevalde, Best way I've found to layout runs & rises is w/points that you can buy at any hardware store!!!! I mark w/soapstone on a 2' square run & rise marks, set on nose line of structural steel channel and set points on edge of channel. NEVER had an error!!!!! Pittsburgh home of the STEELERS

Hello Smooth Operator, have used the stair gage sets you are talking of, have also used a large speed square, and tried a number of other different methods. Sometimes it's simply a matter of using what you have available.

A lot of stairs that I have built have been from prints with the engineering "supposedly" correct and ready to go, you have likely experienced many of those sorts of drawings where you end up needing to "fill in" the missing dimensions due to the drafter being in a hurry or simply missing something, a plan view drawing can be invaluable when you need verification for mistakes or ommissions. Some scratch paper and my calculator have also come in handy for those cases.

I have also been sent out with materials and unspecified directions to build a stair to suit based on what I have found when I have arrived at the jobsite. Those are the instances where I like to do a bit of math to figure out the overall rise and run of the set of stairs, the nosing distances based on the running dimension, and the stringer angle. If I have a bit of extra material to work with I will layout the risers and then take care of the layouts for the bottom and the top of the stringer afterwards. Best regards, Allan

I agree Allan! There's always a job where there have been changes made to the height or depth of the pour, a difference in the thickness of any material that is either added or eliminated from on top of the concrete pour, etc. These changes are made without informing the detailer or structural contractor beforehand and therefore require that the field personnel adapt from the drawing they're supposedly following in order to install the stairs... The easy part of fabricating the stairs is doing the shop layout and fabrication, but when installing the stairs in the field, there is almost some sort of change that must be made for the stairs to be properly installed so that there's no rework to be done on a later date in the construction schedule because of a lack of communication between the contractors and subs also.

That's why those friggin mostly boring and repetitive weekly meeting must be attended in order to avoid those potentially embarrassing incidents where a contractor ends up having to eat the charges for not keeping up to date with any changes made during the construction process. ;)

Respectfully,

Henry

ssbn727, The #1 rule I have found for fabbing stairs, ladders, handrails,etc. "NEVER FAB. UNTILL YOU CAN GET FIELD MEASURES" , if the customer/ contractor doesn't like it, ask them to sign off on fabbing to just drawings. All of a sudden they start to back pedal !!!!!!! As for weekly beatings, I mean meetings, least favorite part of job, but if you don't go other trades will BLAME you for any problems/delays !!!!!! Pittsburgh home of the Steelers !!!!!!