Gentlemen,

Overall I agree as well. I would direct any who would be so inclined to review this thread:

http://www.aws.org/cgi-bin/mwf/topic_show.pl?pid=193959;hl=D1.1%202.2.5.3 . I still believe that stand completely.

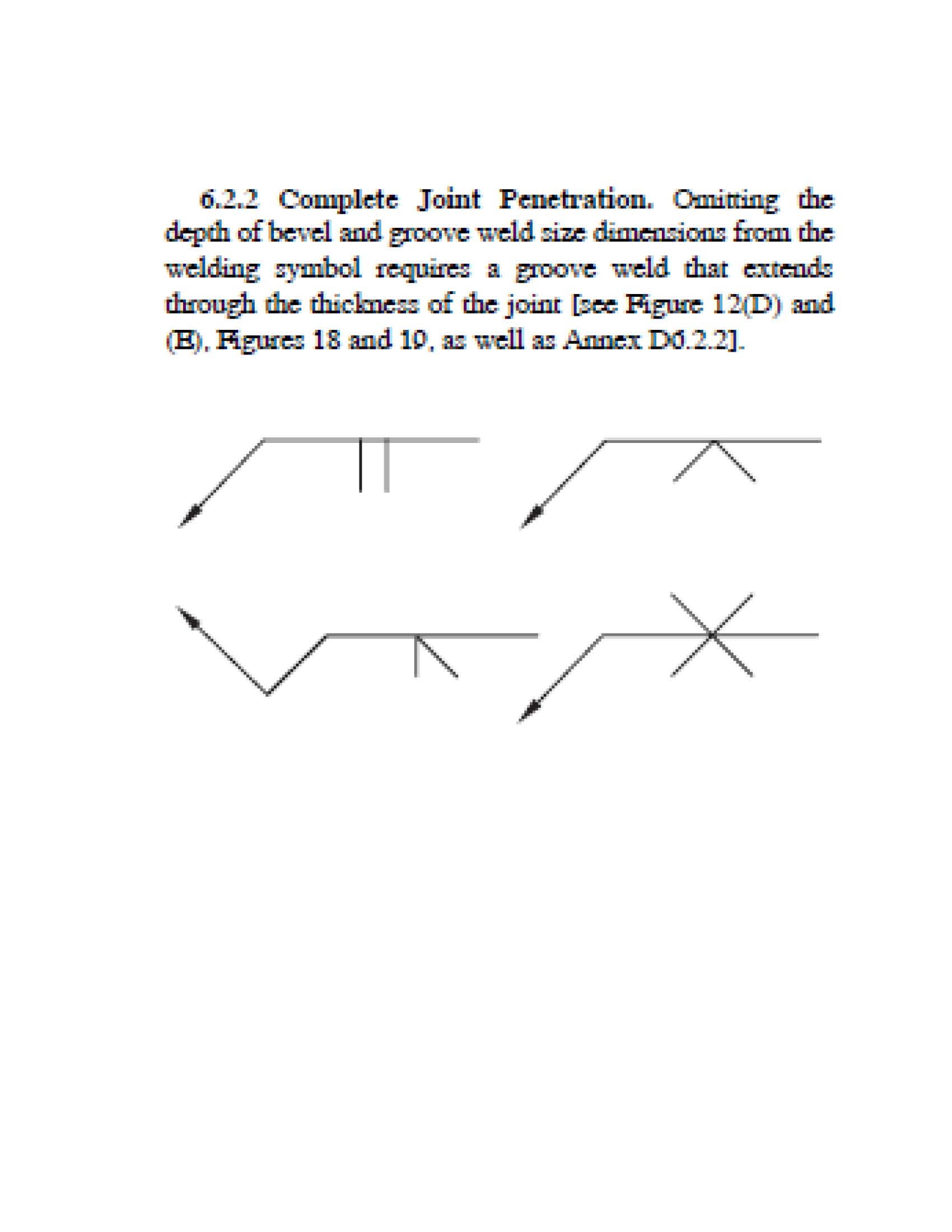

Now, having said that, my first post is not to reflect that it would not in practice be a CJP. But to what extent does it MANDATE CJP? Will it have to be UT'd to prove 100% CJP?

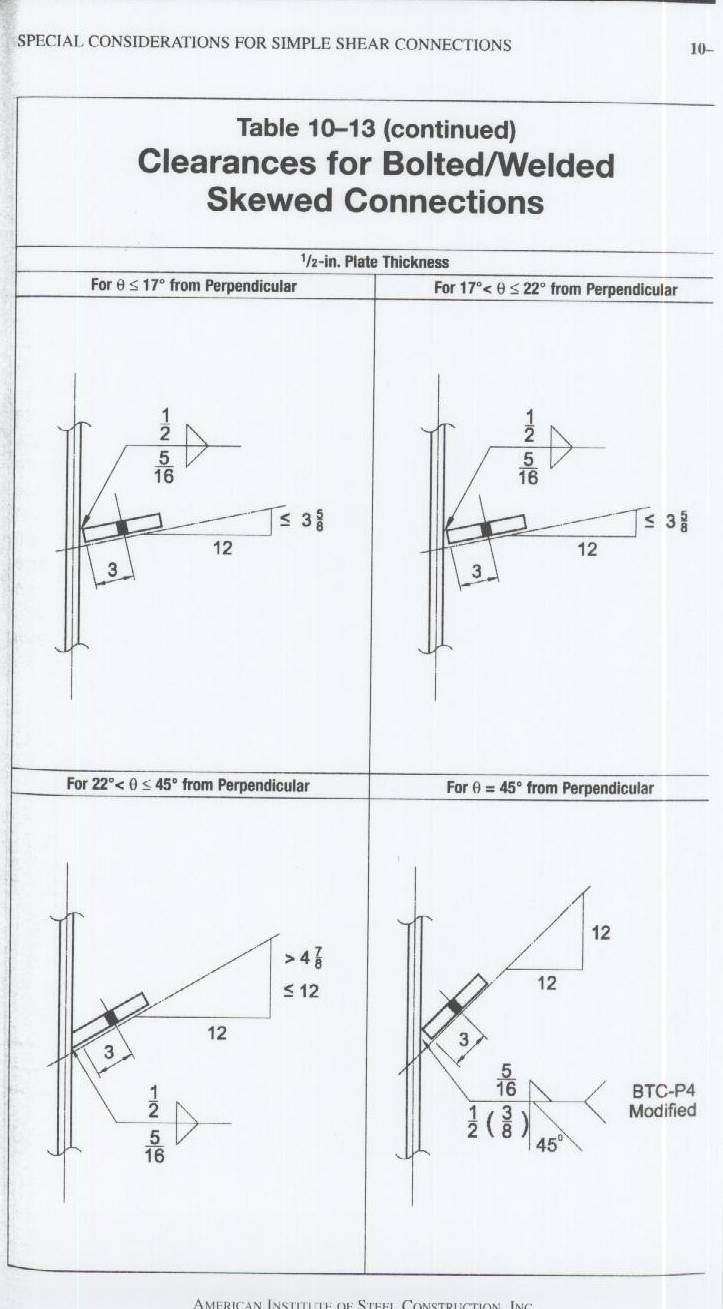

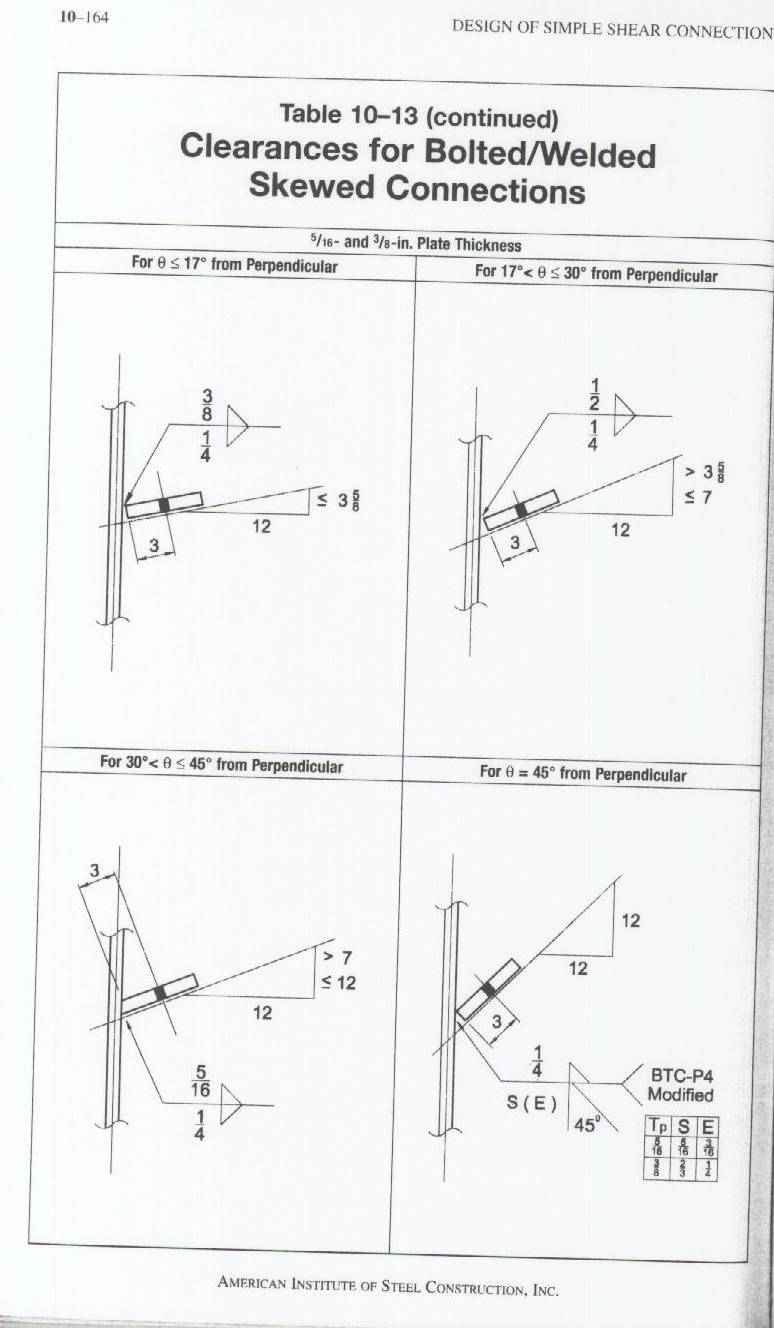

The lack of size and CJP being incorporated into the welding symbol apply to groove joints, but how about in SKEWED JOINTS? Please note D1.1, Clause 2, 2.2.5.2 'Fillet Welds and Welds in Skewed Joints'. As well as my previously mentioned A2.4, 6.13 & 7.7 with Figure 31. All state the REQUIREMENT that a detailed drwg be included which would show all necessary dimensions. Slightly different than the CJP being presumed in joints of standard configuration. Specifically the Z loss factor is to be accounted for.

2.2.5.2 paragraph (2) "For welds between parts with surfaces meeting at an angle less than 80* or greater than 100*, the shop drawings shall show the detailed arrangement of welds and required leg size to account for effects of joint geometry and, where appropriate, the Z-loss reduction for the process to be used and the angle,"

A2.4, 6.13 "Skewed Joints. When the angle between the fusion faces is such that the identification of the weld type and, hence, proper weld symbol is in question, the detail of the desired joint and weld configuration shall be shown on the drawing with all necessary dimensions (see Figure 31)."

Now, one oversight then on my part would have been to stress the need to have already used the RFI system to clarify the symbol and it's desired result. It should not be left to the Contractor/fabricator nor to the inspector to guess the intent of the engineer.

But, on the face of it, I don't see how it could be concluded that the symbol in question MANDATES CJP, until the engineer speaks out, since it is missing critical components according to A2.4 & D1.1, 2.2.5.2. There is a detail of the joint but it lacks the REQUIRED dimensions.

Again though, in practice, with that angle it may well be a CJP when the weld is completed. But if it is MANDATED then one needs to take care to make sure the two welds meet. The Z-loss area can mess up many welders if they don't do proper backgouge/grinding.

Just my two tin pennies worth. Please don't count me, necessarily, as being the 1/4 of the replies that are WRONG. There is more here to my estimation than just the CJP because there are no dimensions. I am not afraid to take a differing stand here as long as we don't start a feud over it. Like I said, overall I agree with the CJP requirements on welding symbols lacking dimensions. But, Nalla needs to go to the engineer. That is always the best course, especially if there is disagreement between the interpretation of the Fabricator and the inspector.

Have a Great Day, Brent