By 803056

By 803056  Date

Date 03-29-2011 03:56

Edited 03-29-2011 04:12

John, I’m sorry to hear you are experiencing poor health.

My wife has been having problems since she hit her early 40's and it has affected every aspect of her daily life.

You did a good job of trying to answer the question considering you don’t have access to the latest edition of ASME Section IX.

This is my take on the subject. The welder uses a qualified WPS when he is tested, but he is not limited to the one WPS once the test is completed and all the requisite tests have been passed. The WPS has specific ranges for which it is qualified, but the ranges for welder performance are not limited by the same articles as the WPS, i.e., different tables list the limits of thickness ranges for the WPS and performance qualification.

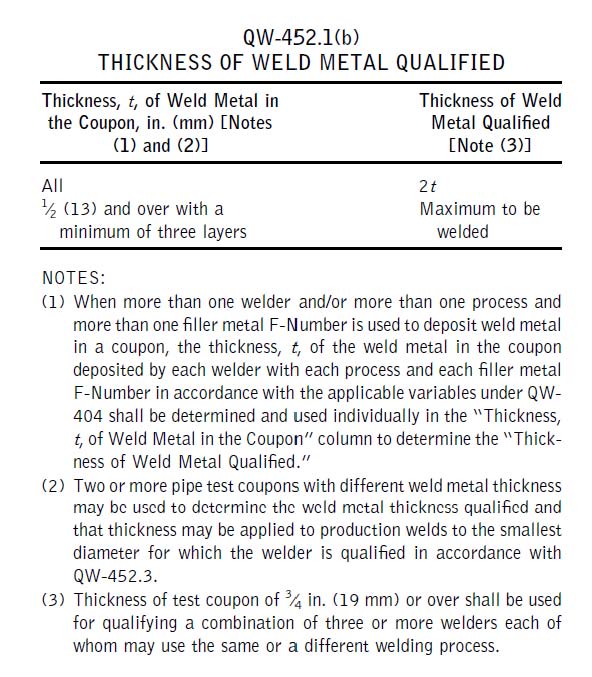

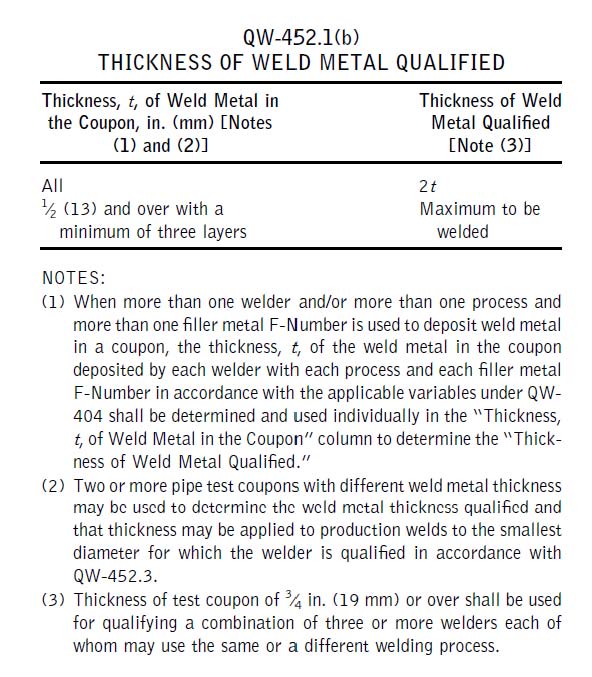

ASME Section IX allows the welder to be qualified for unlimited thickness if the test coupon is at least 1/2 inch thick and the weld is deposited in no less than three layers. No lower limit is listed for the thickness range qualified regardless of the test coupon thickness. This allows a welder to use a WPS that was originally qualified using 1 5/8 inch plate, i.e., the PQR test thickness. While the WPS used for performance qualification is qualified for thicknesses between 3/16 inch up to 8 inches thick, the welder is not limited to 8 inches if the contractor has a different production WPS qualified for thicknesses over 8 inches.

Welder qualification does not include a requirement for notch toughness. However, where notch toughness is a requirement for the construction code, the WPS must be qualified for toughness and the welder must follow the WPS and work within the listed ranges of voltage, amperage, and travel speed if those variables are used by the WPS to control the heat input.

I hope your health problems are a passing thing and you recovery is imminent.

Best regards - Al