Thank you for your kind words electrode...

Btw, I do have volume 1, "Welding Science and Technology" by A.C. Davies...

The volume you have in the link 46.00 posted is "The Science and Practice of Welding" which is different in format and content although interesting as is the volume I have.

I'm going to quote from "The Science and Practice of Welding" starting from page 160.

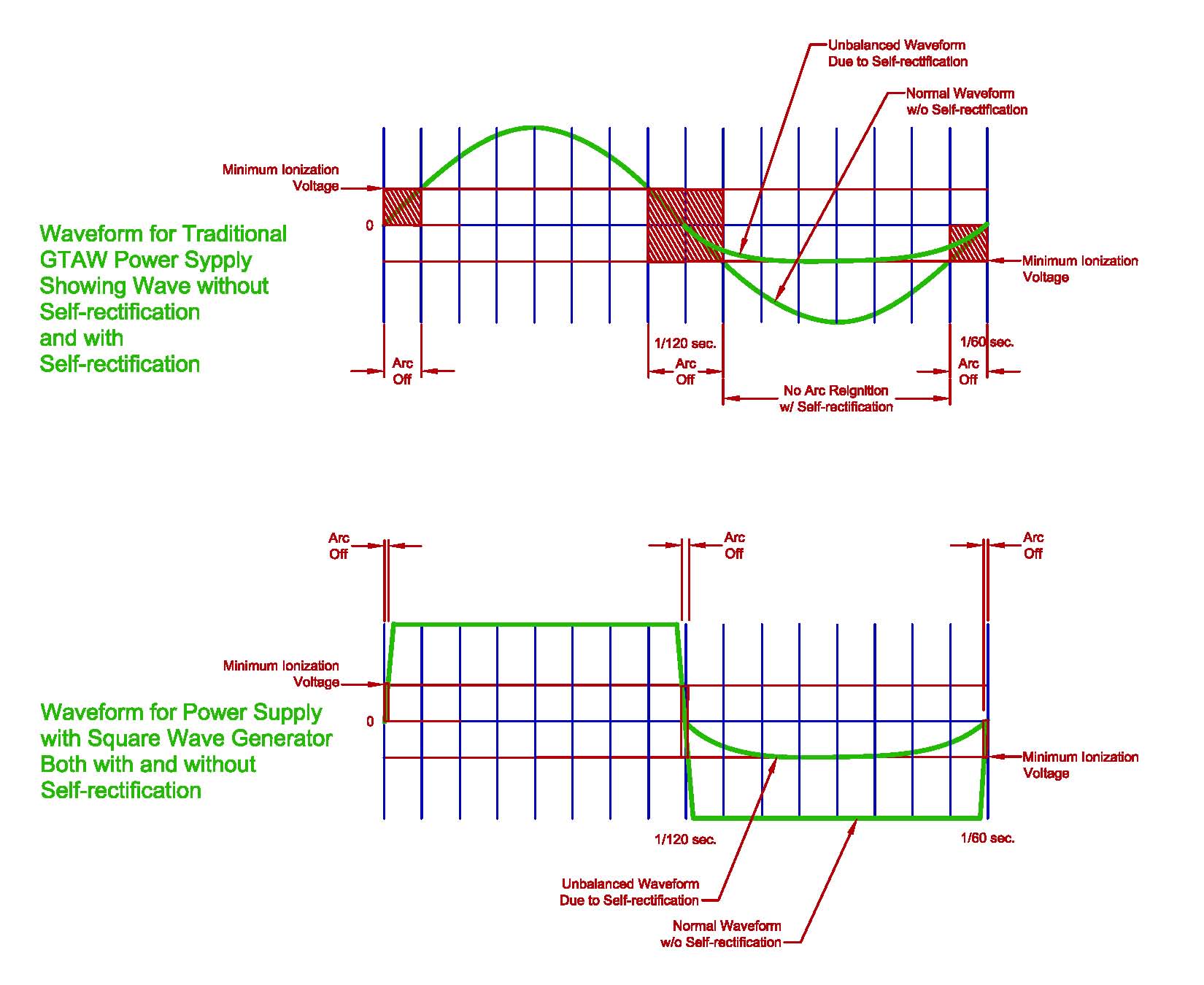

Quote; "Square wave power output units (AC/DC). Power units are now available in which the voltage and current waves are not sinusoidal, but have been modified by solid state technology and using printed circuit boards (P.C.B's) to give a very rapid rise in the AC wave from zero value to maximum value to give a square wave output.

When GTA welding of aluminum using a sinusoidal wave form current, the arc tends to become unstable and the electrode is easily overloaded.

This gives

tungsten inclusions in the weld (spitting) and leads to faults in the weld bead and more rapid consumption of the

tungsten electrode.

Square wave current overcomes these drawbacks and the arc is greatly stabilized and the risk of

inclusions greatly reduced.

In addition, MMA (SMAW) welding characteristics are greatly improved and the arc is smooth with reduced spatter.

The units are designed for AC precision welding of Aluminum etc. and for DC TIG (GTAW) and Manual Metal Arc welding or MMA (SMAW).

they have a transformer and silicon bridge rectifier, SCR (Silicon Controlled Rectifier) or thyristor with a square wave output. A memory core stores energy proportional to the previous half cycle and then injects it into the circuit just as the wave passes through zero at the beginning of the next half cycle.

The rapid rise of the wave from zero to maximum, of about 80 microseconds from peak to peak means that the high frequency and high voltage at the beginning of the cycle needed in order to initiate the arc and often to keep it ionized without touchdown, need only be applied when the arc is first initiated. After this first initiation the HF is switched off automatically."

Well this doesn't give me a complete answer to your student's query Larry so I decided to look in a publication more suitable for folks on this side of the pond and I came across with this: AWS Welding Handbook ninth edition, Volume 2, Welding Processes part 1, Chapter 2 Shielded Metal Arc Welding, age 94, Arc Stability.

A stable arc is required if high quality welds are to be produced. Discontinuities , such as incomplete fusion, entrapped slag and porosity (blowholes), can be the result of an unstable arc. The following are important factors influencing arc stability:

1. The open circuit of the power source.

2. Transient voltage response characteristics of the power source.

3.Size of the molten drops of filler metal and slag in the arc.

4. Ionization of the arc path from the electrode to the workpiece.

5. Manipulation of the electrode.

The first two factors are related to the design and operating characteristics of the power source. The next two are dependent on the type of welding electrode. The last one represents the skill of the welder.

The arc of a covered electrode is a transient element in the circuit even when the welder maintains a fairly constant arc length. The welding machine must be able to respond rapidly when the arc tends to extinguish because of the resistance of the arc momentarily increases or when a large droplet partially or totally short circuits in the gap. In these instances, a surge of current is needed to restore the arc. With AC, it is imperative that the voltage cycle leads the current cycle to sustain the arc. If the voltage and current were in phase, the arc would be very unstable. This phase shift must be designed into the welding machine/power source.

Some ingredients of the electrode covering tend to stabilize the arc. These are necessary ingredients for an electrode to operate well on AC. A few of these ingredients are titanium dioxide, feldspar, and various potassium compounds (including the binder, potassium silicate). The

inclusion of one or more of these arc stabilizing compounds in the covering provides arc plasma that readily ionizes and achieves a quiet arc. Thus, the electrode, the power source, and the welder all contribute to arc stability."

This was simple enough to go over yet I wasn't satisfied either Lawrence, so I kept digging for more... I'll post it tomorrow because I need some rest... I'm worn out from all the drugs and the crap of being ill...

Respectfully,

Henry

ry

ry

I dearly do not like Quantum Mechanics...everything I read on it usually results in a headache. Lets get Einsteins dna and boot up another copy of him so he can make QM actually work for those guys with an addendum to relativity. Sorry off subject.

I dearly do not like Quantum Mechanics...everything I read on it usually results in a headache. Lets get Einsteins dna and boot up another copy of him so he can make QM actually work for those guys with an addendum to relativity. Sorry off subject.