By 803056

By 803056  Date

Date 10-12-2013 15:32

Edited 10-12-2013 15:47

Hello C.T.;

You are on the mark concerning welders failing to appreciate the proper technique of back gouging and the proper geometry required to obtain sound back welds. Welders assume the back weld will penetrate and fuse any traces of the original root remaining after back gouging and they fail to appreciate the need for proper geometry to provide proper access.

I had one client in the Midwest hire me to teach their welders the proper technique and the geometry needed to secure a sound back weld. Management told me they had one project where they had to go back and make field repairs to a large number of joints after the structure was erected and completed. The Owner's inspectors discovered none of the CJP groove welds were CJP because of the welders' failure to back gouge properly. The total repair bill cost the fabricator over 6 million dollars.

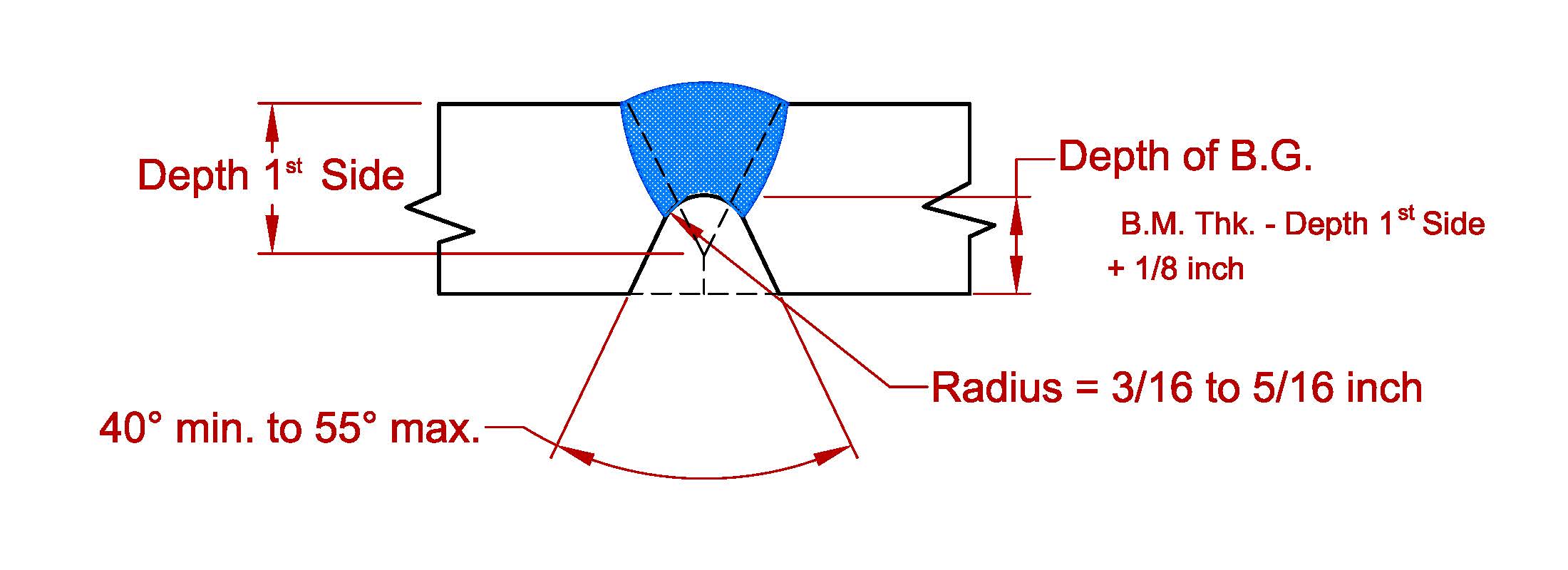

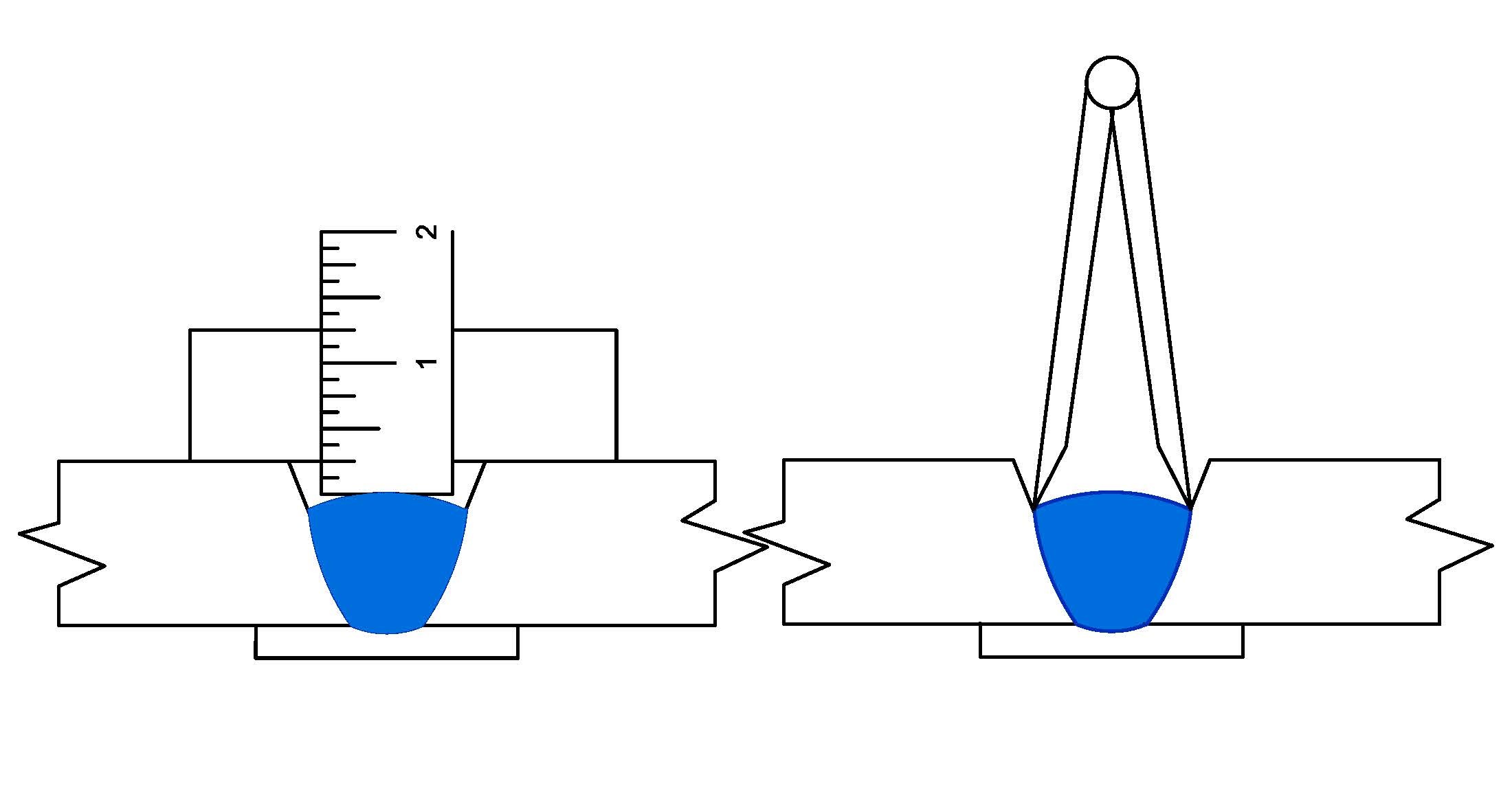

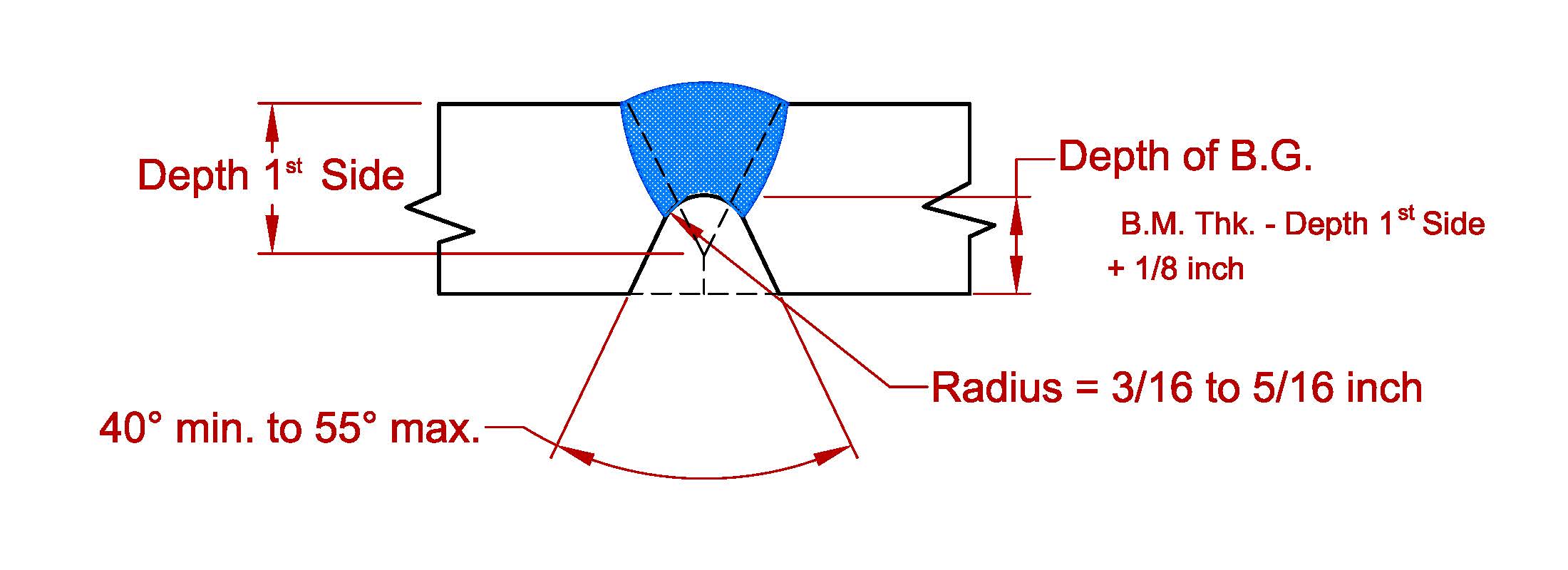

I require the welders to follow the directive hidden in AWS D1.1 that specifies the back gouge should resemble a prequalified U-groove or J-groove. The bevel radius for the U-groove ranges from 3/16 inch minimum to 5/16 inch maximum. The groove angle ranges from 40 degrees minimum to 55 degrees maximum. The depth of the back gouge is no less than the thickness of the base metal minus the depth of the bevel on the first side plus a 1/8th inch. The attached graphic depicts the dimensions required.

Some welders argue that the amount of metal is excessive, but my response is that it works every time. The cost of the extra metal is a fraction of the cost of repairing the weld because they were too lazy to deposit one or two extra weld beads. The cost of repair is several times the cost of the original weld. The consequence of a bad CJP can be financially catastrophic to a fabricator if it isn't discovered during fabrication or if there is a structural collapse.

As the TPI, I have to tread lightly lest my comments be construed as interfering with the fabricator’s responsibility to provide the method and means of meeting the code. I had one contractor located on the West Coast put himself out of business because they failed to back gouge deep enough and they didn’t provide the necessary geometry to produce sound welds in Zirconium. Strange stuff that Zirconium! The contract only allowed one repair. If the first repair attempt was not successful, the part was scrapped. I suggested to QC they might consider performing radiograph on the first few assemblies to ensure the welds were sound. The QC manager insisted they were going to weld all 50 assemblies and radiograph the completed batch. All 50 parts were rejected. The welders begged me to make the fabricator open up the back gouges so they could deposit sound weld. QC refused to relent and refused to allow the welders to open up the back gouges. The bottom line was all 50 parts were rejected at a cost of 30K each. The company couldn’t absorb the financial lost and went bankrupt. My client’s position was at I could ask questions, but it wasn’t my responsibility to interfere with the contractor’s activities and that I was not to offer suggestions, advice, or direction. My responsibility was to report my observations to the client and let the fabricator sink or swim. Unfortunately, the fabricator wouldn’t listen to my questions and they refused to listen to their welder’s requests to modify the back gouge to provide them with better access for the back weld. They sank like a heavy stone.

Best regards - Al