Not logged inAmerican Welding Society Forum

Hello All

These can be bought commercially but they are simple to make, so I thought I would share with the group how I make them. This one is for use in 6” pipe. These are good for us guys who work in the shops doing shorter assemblies who want to save purging times and argon usage.

• Lay a short piece of pipe down on a piece of 1/8” rubber

• I bought this rubber at a plumbing supply store, nothing special.

• Using a marker I scribe the inner and outer diameters onto the rubber.

• I use a pair of scissors and cut the rubber half way between the two marks

• Cut two round plates out of 16 gauge material. I cut them a ½” smaller than the pipe size being used, in this case 5 1/2”

• Drill out the center of the 16 gauge circles and rubber circle to allow for a bolt to pass through to bolt them together

• Bolt them together.

• Drill four holes for a ¼ -20 bolt to pass through around the outside and bolt them together

• I use two 3/32” holes near the center to allow for purging.

• Sometimes I allow for a tube to attach a purge hose to as well, in this case I fed it through a coupling

• I weld a nut on top of the bolt to be able to attach different lengths of T handles depending on the length of pipe I’m welding

Regards

Jim

That is a helluva lot nicer then masking tape!!!!!! I use to just cut me some sheet metal squares, cut a hole for a hose and then tape it all up. If you are doing pipe regular that is a slick way to go. I see you got your exhaust/weep hole in it as well...it amazes me watching people purge stuff and they forget an escape route for the oxygen. Good Job.

Necessity, the Mother of all inventions.

Nice, very nice.

Just a little twist to a great idea; use a piece of pipe with a “quick connect” fitting welded to your plate so your purge gas hose can be connected quickly and easily.

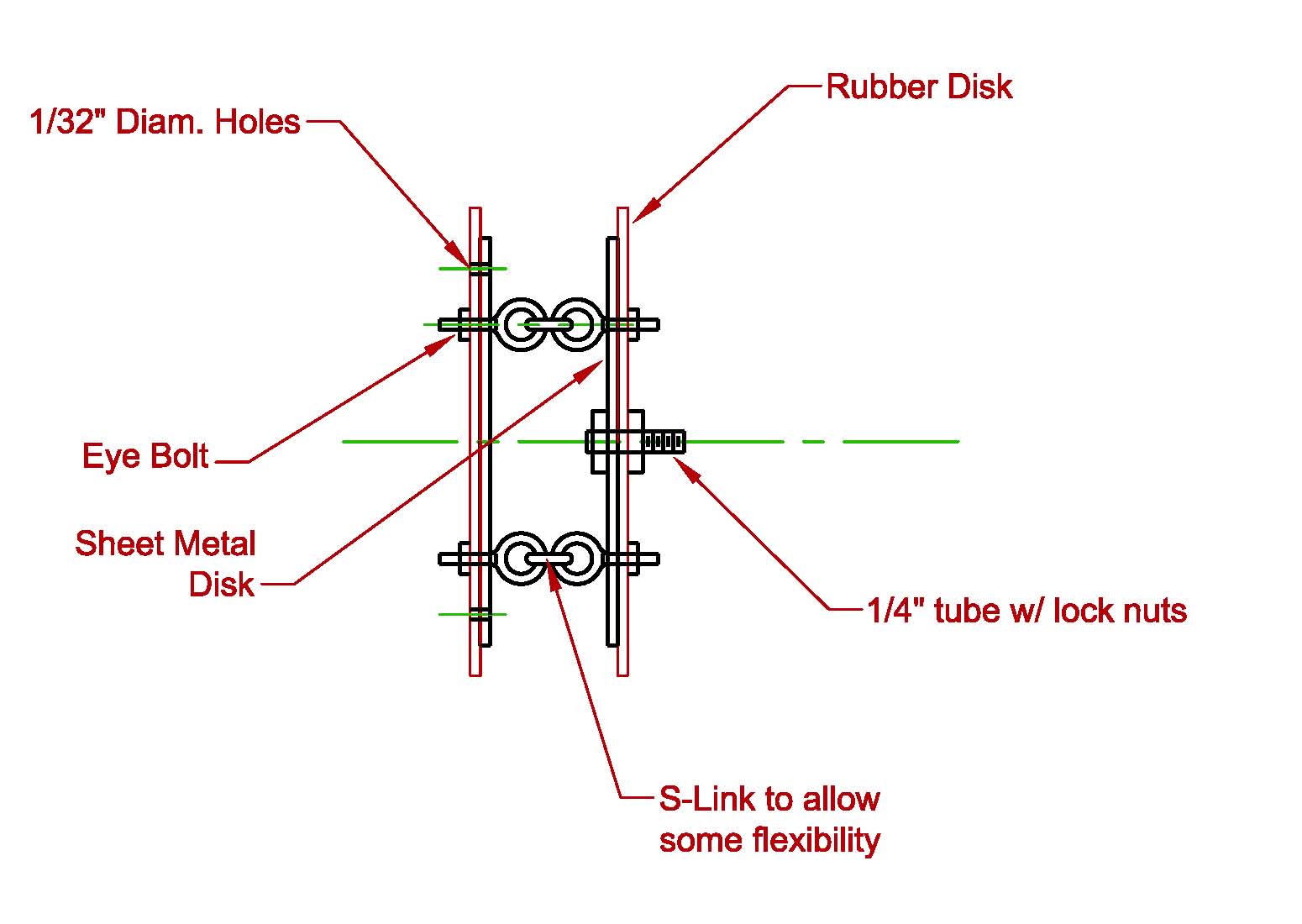

Two of your purge dams can be used to effectively reduce the volume that has to be purged. Simply put a dam to either side of the joint. They can even be connected with spacers consisting of eye bolts so they can be maneuvered through elbows. Push the dams beyond the joint and then pull it back to straighten it out or use a length of chain fished through the pipe spool and pull the dams into position.

Best regards – Al

Powered by mwForum 2.29.2 © 1999-2013 Markus Wichitill