D1.2:2008 does not contain the 1/8" minimum thickness limitation of D1.1. PQR test coupons (assuming you qualify a PJP procedure only) must be submitted for visual, macroetch and bending. (I would recommend doing a 2F with actual production materials, unless you will have to weld out of position.) Table 3.6 contains the number of specimens for each test: Going by 2. Tests on Pipe and Tubing; (See fig. 3.18) 2 macros, 4 or more fracture, qualifies to unlimited plate t and max. fillet weld size and smaller. Probably the greatest part of the cost would be the labor, which you might want done by 3rd party.

6061-T6 is very forgiving when welded with ER4043. The weld and the HAZ are somewhat more ductile than the surrounding base metal, probably equivalent to a T4 but no guarantee of that. The great advantage of using 4043 is that you can heat treat your weldment to strengthen it. If you are anodizing and not performing a subsequent paint job, you will need to switch up fillers. ER5356 provides a good color match after anodize; however if you try to heat treat the weldment the 5356 welds will crack (5356 also does not do so well when you have to use a lot of restraint to prevent distortion). As far as strength goes, OSHA has a requirement for handrails to restrain 400 lb. horizontally. As a demonstration of one of my product's compliance, we placed an 800 lb. weight on the end of a 36" long 2x2x.19" wall 6061 tube inserted into a 2.5x2.5x.25" wall socket fillet welded (GMAW ER4043, no PWHT) on two sides to a 2x4x.19" tube. The "handrail post" didn't bend. and the welds sustained no damage. I should find the photos of that and post one. Very informative testing that day!

Anyway, good luck. And remember: CLEAN, CLEAN, CLEAN.

EDIT: I meant testing when I said 3rd party.

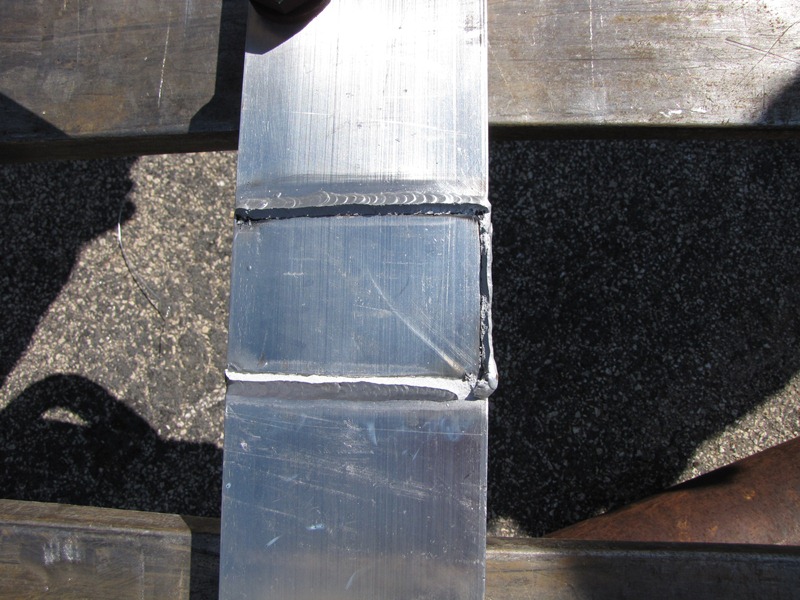

Edit #2: Okay, found the photos. The requirement is for the handrail to hold 400 lbs, and each rail has 2 sockets. So the static test was for one socket. We also used this test to show the difference between vertical welds uphill vs. downhill. This is all 6061-T6 as-welded, no PWHT, GMAW, ER4043 filler.