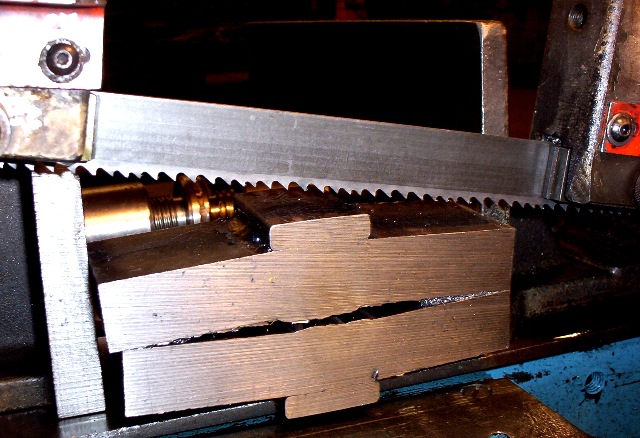

Hello folks, just did a WABO test the other day and came up with a pretty pronounced case of "overlap" thought that some of you would appreciate the image. I have been at this for quite some time and I do believe this is one of the most extensive examples that I have put my eye balls on. The majority of the plate actually looked pretty good, that is, until the gentleman went to put the cover passes on. Had to look this one out, although I always go ahead and cut and bend them anyway just to give the tester an idea of how the rest of the weld performed. This was a vertical plate and the welding was performed within parameters. I personally feel, however, that he was at the lower end of the voltage and the upper end of wire speed in this instance. Hope you find this interesting. Best regards, Allan