http://www.arcos.us/inserts.asphttps://pubs.aws.org/Download_PDFS/A5.30-A5.30M-2007PV.pdfhttp://robvon.com/

http://www.arcos.us/inserts.asphttps://pubs.aws.org/Download_PDFS/A5.30-A5.30M-2007PV.pdfhttp://robvon.com/This is from Robvon's website:

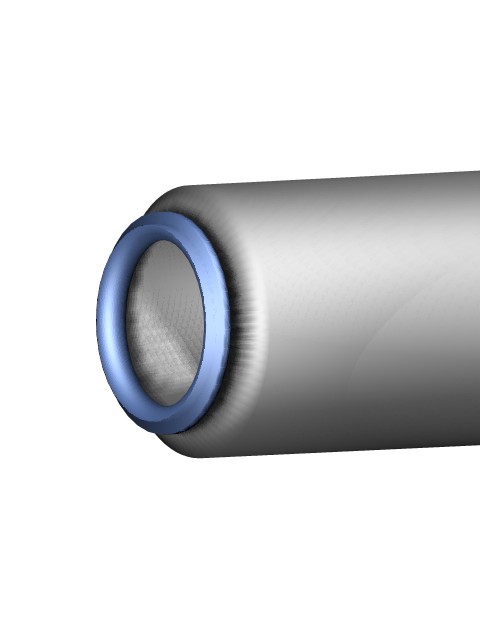

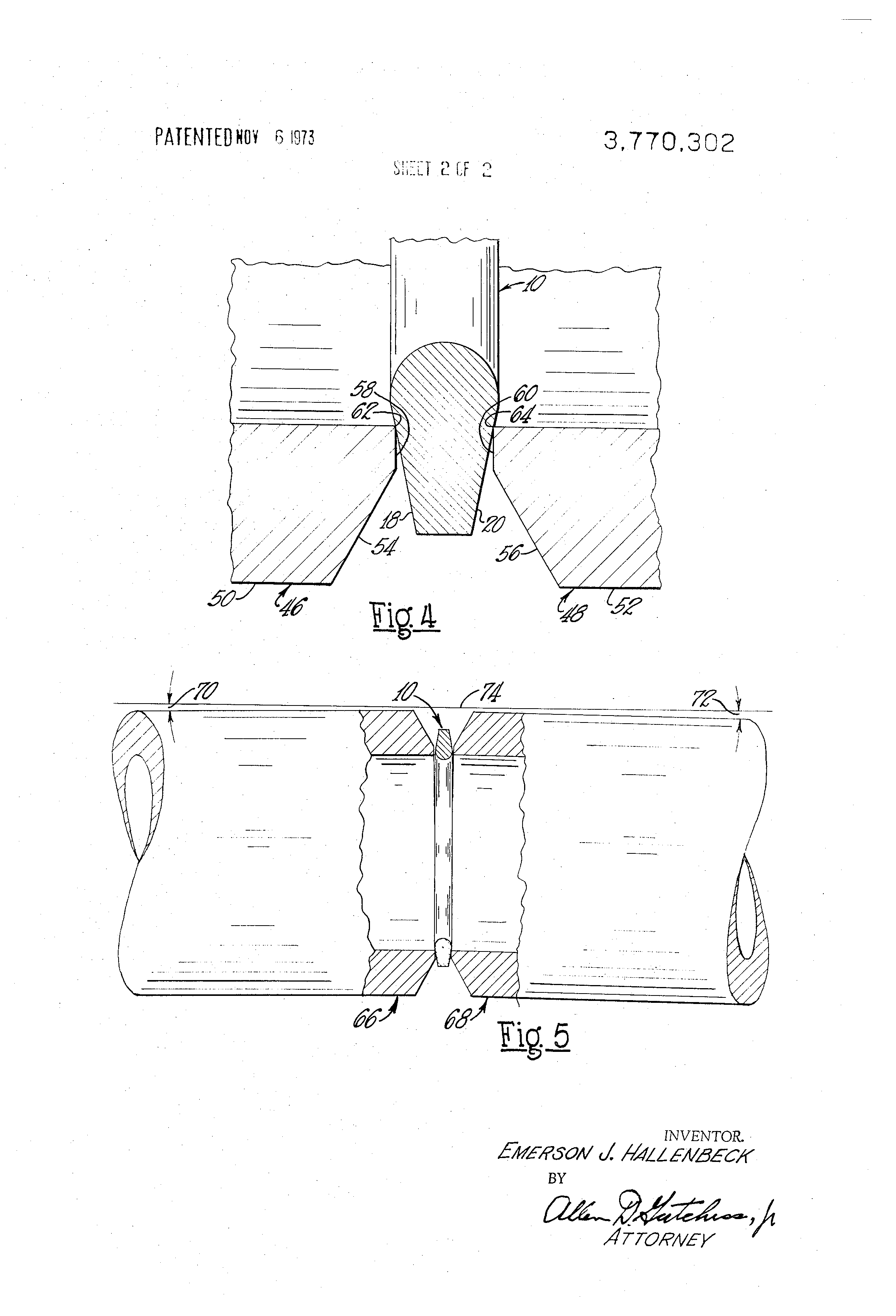

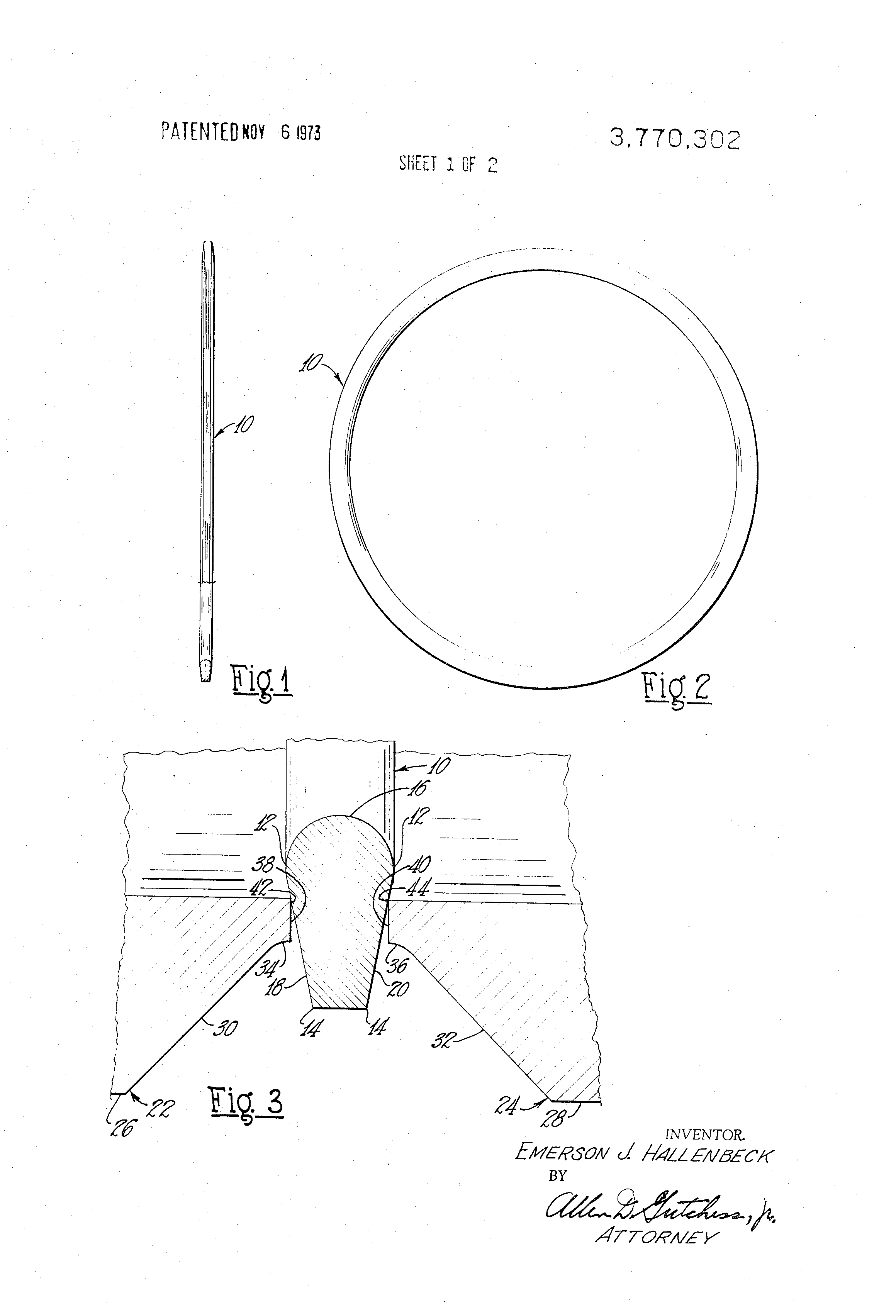

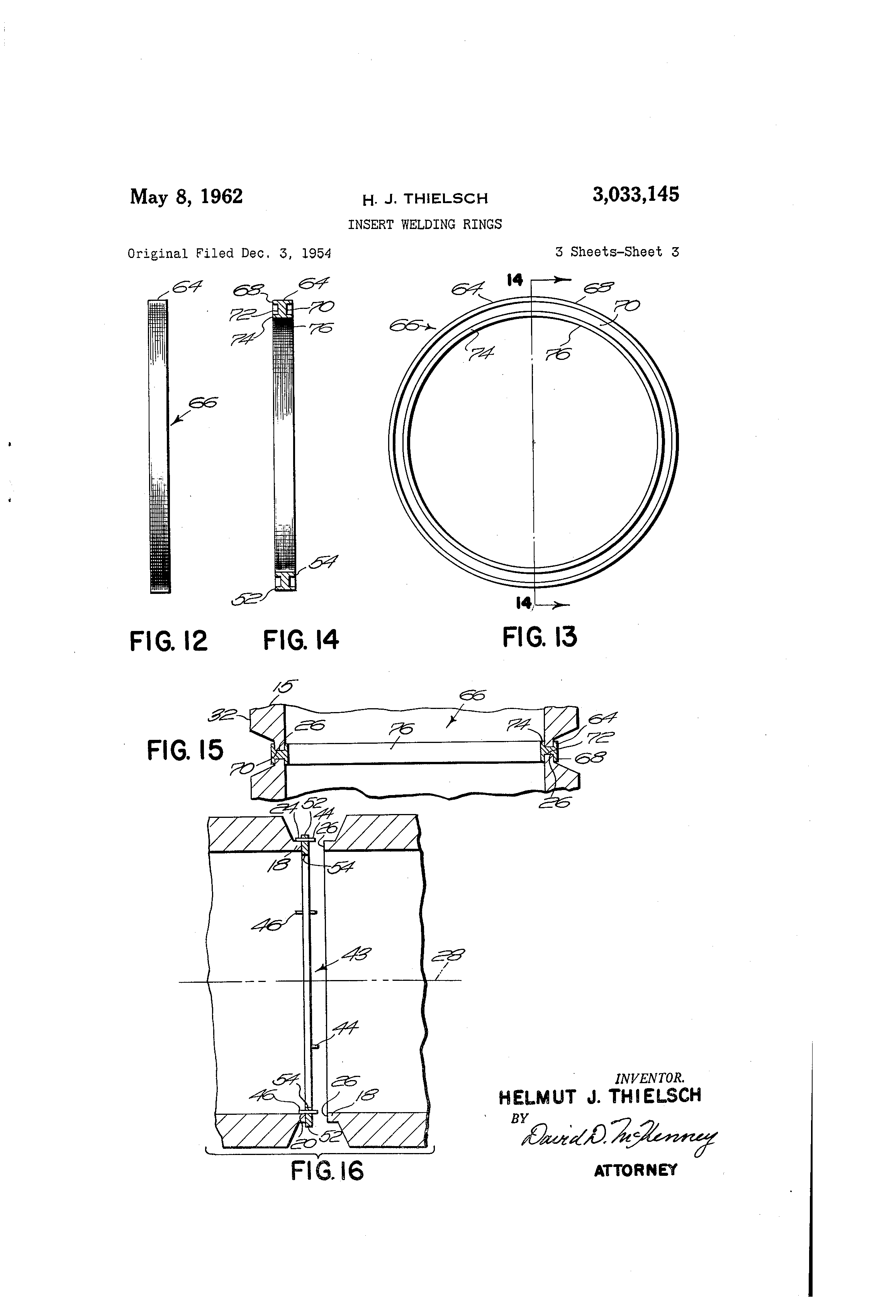

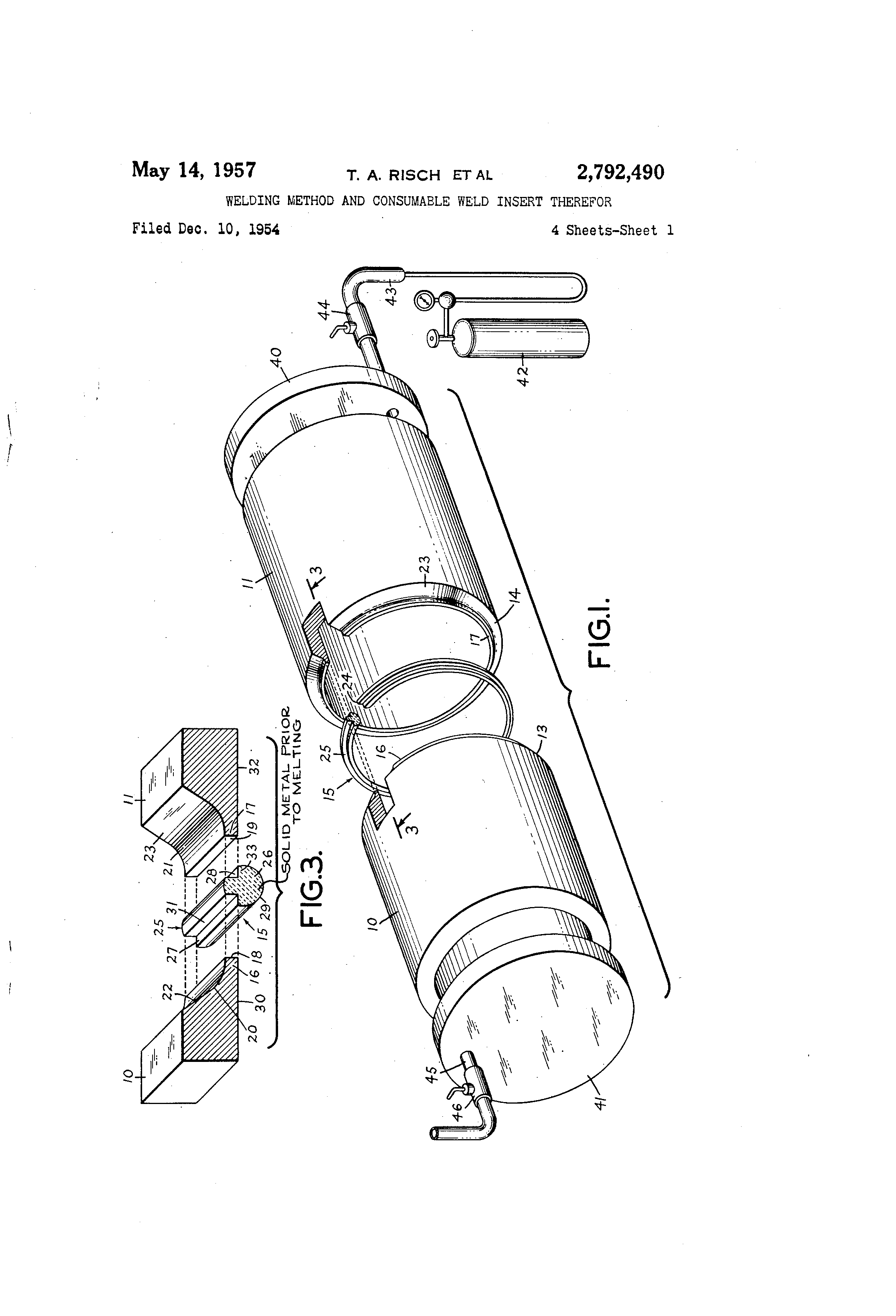

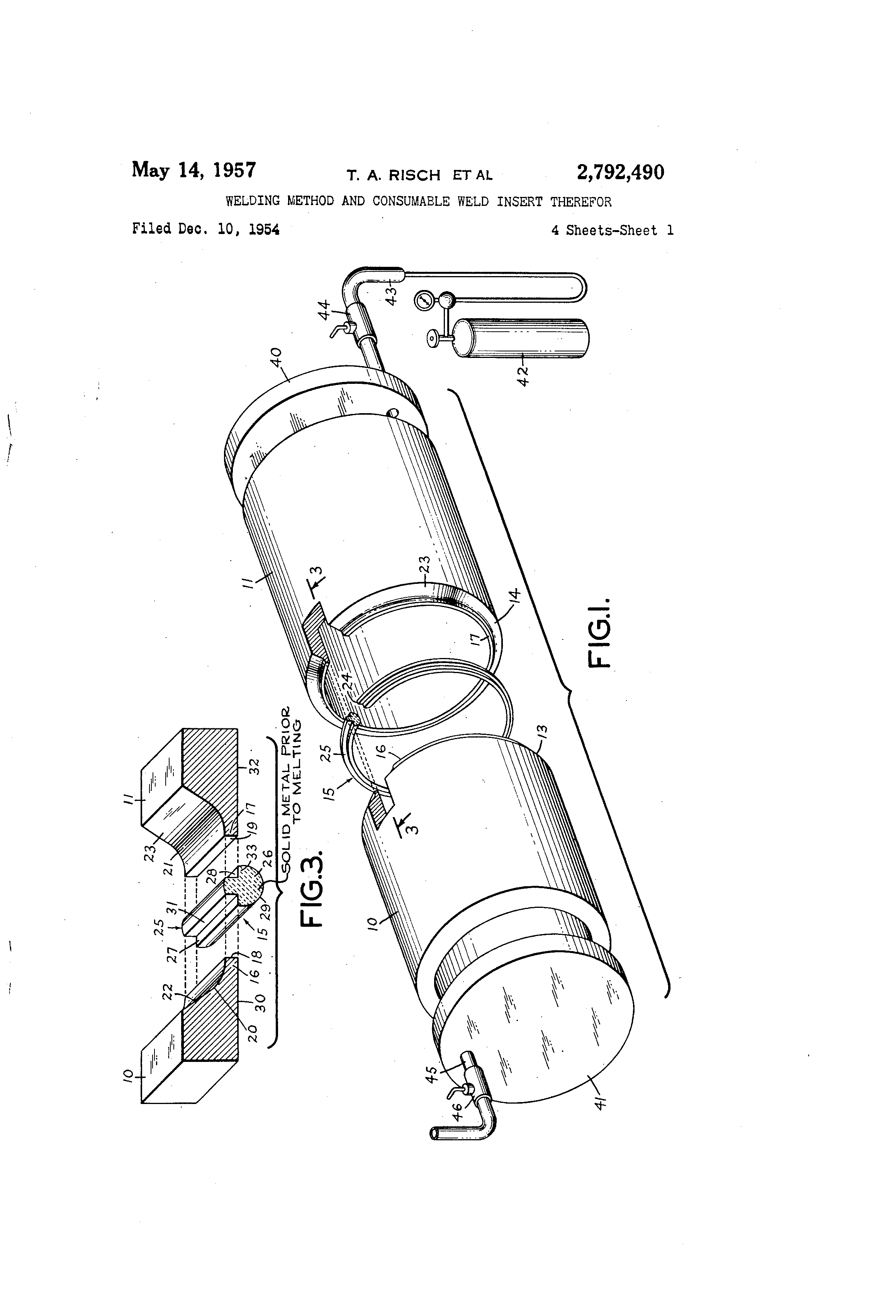

Consumable Insert Welding Procedure:

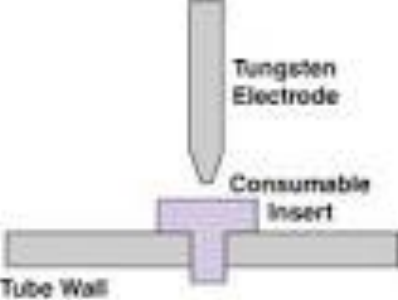

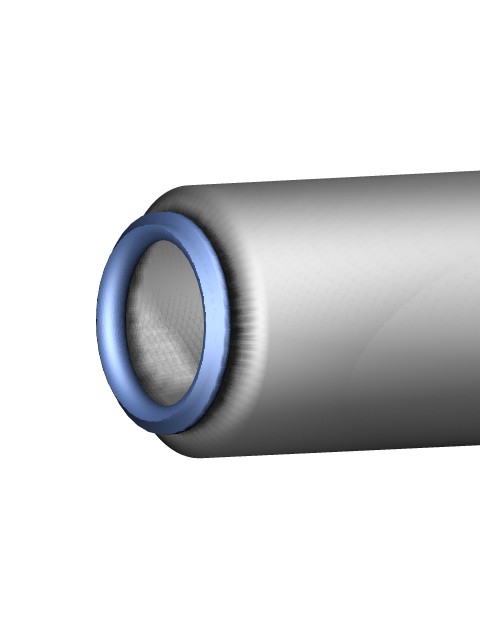

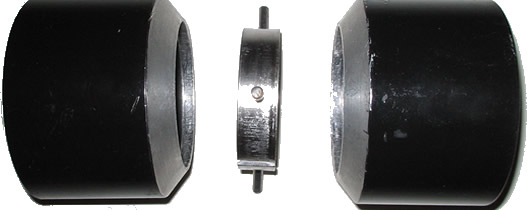

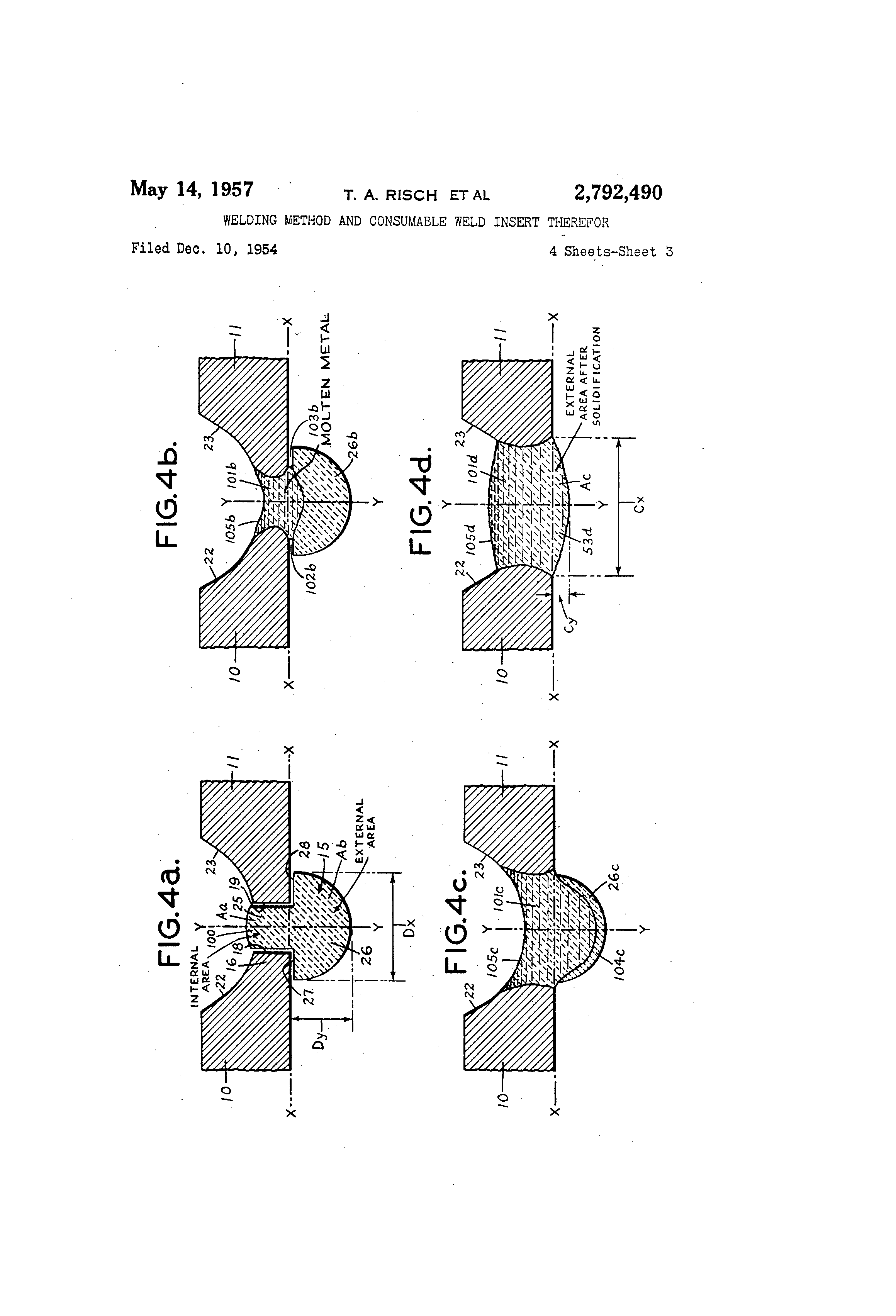

The Robvon Consumable Insert Ring is to be used with tungsten inert gas (TIG) GTAW. DC and Straight polarity is used for "TIG" welding.

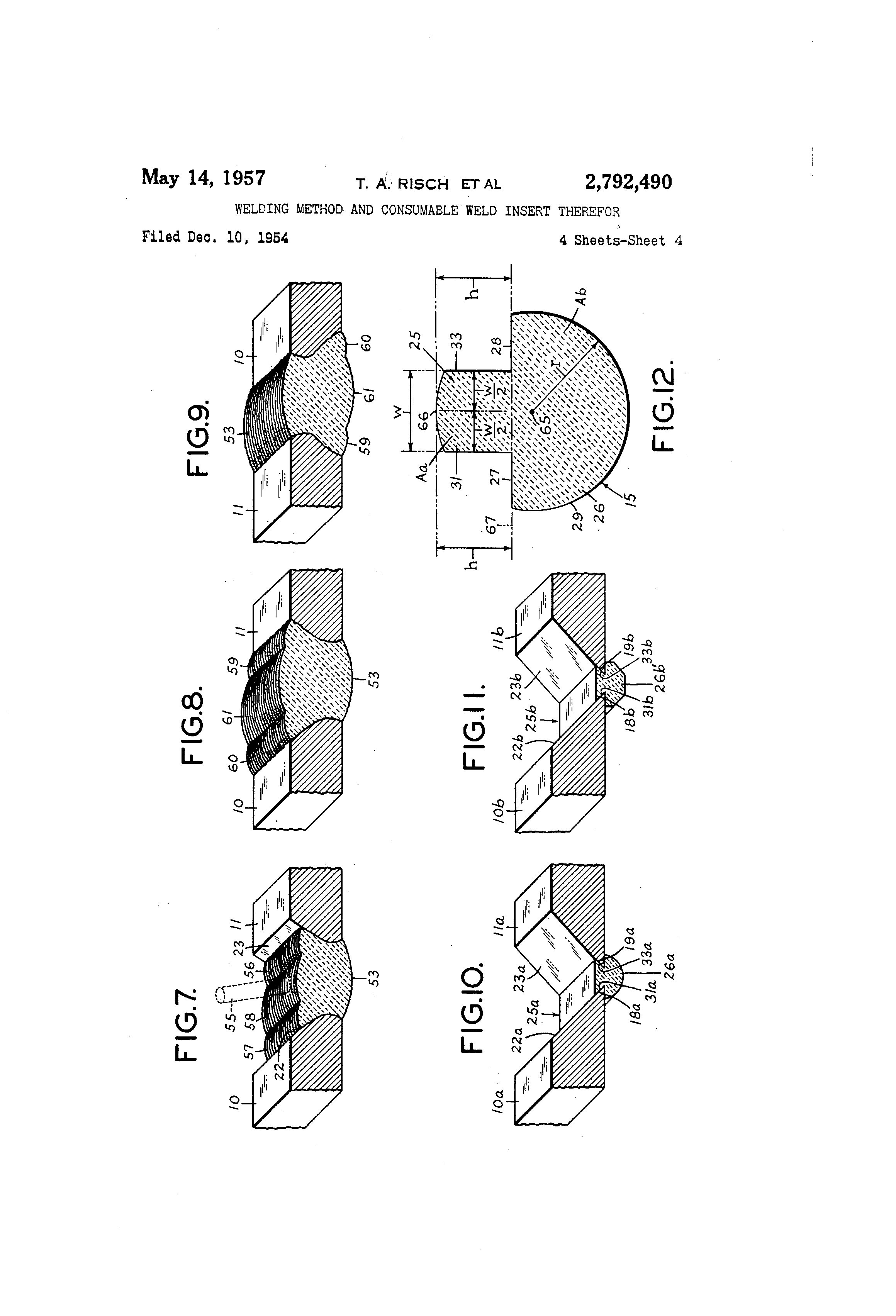

The weld joint and immediate adjoining area of parts to be welded should be prepared by machining or grinding. To assure consistent weld quality, cleanliness must be emphasized. Only rubber bonded (not resin) aluminum oxide wheels should be employed for grinding with stainless steel brushing to follow for complete foreign particle removal.

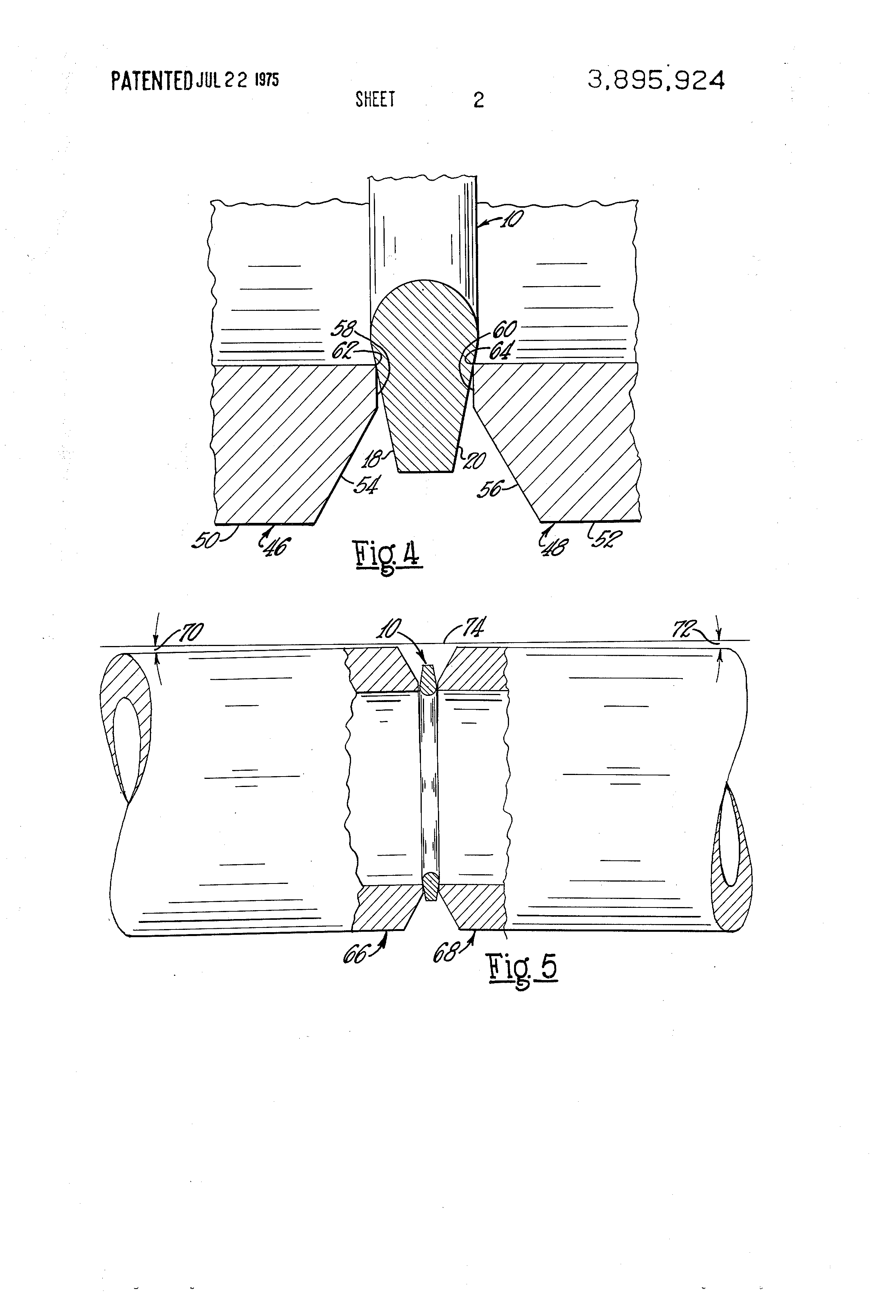

After joint cleaning and alignment, and prior to welding, it is important that inert purging gas be employed in sufficient quantities to assure a smooth, clean underside free of undercut, overlap porosity, oxides, freedom from lack of fusion, etc.

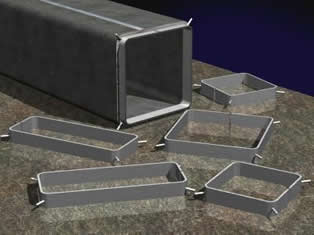

Root welding is accomplished with Robvon Consumable Insert Ring and "TIG" GTA welding process using inert (argon or helium)gas backing. To create a positive atmosphere, purging dams should be used.

Purging at a flow and pressure to accommodate a flushing of six (6) times the volume of the piping or section of blanked-off area is usually adequate. While still maintaining a positive inert gas backup, the purging flow and pressure are reduced to a flow of approximately 2 SCFH using a venting valve or relief system to prevent internal pressure build-up while the root welding is accomplished. Insufficient internal positive gas pressure will allow excessive penetration or fall-through while excessive gas pressure will result in concave and incomplete root-bead penetration.

The choice of amperage, Tungsten electrode size, arc length, shielding gas, nozzle size and gas flow will depend on the thickness of the material in the joint areas and the speed of travel or capability of the operator. Generally, the use of argon/helium shielding and backing gas is recommended for greater welding speed and improved weld quality. A flow of 12 to 20 SCFH, depending on the nozzle size and amperage, will be adequate. An area of amperage setting for "TIG" GTA welding is to use 1 amp for each .001" thickness of material to be fused. To avoid crater cracking and shrinkage, it is suggested that remote current control be used with the arc to be started and ended on an immediately adjoining copper tab or starting block without interruption of the arc.

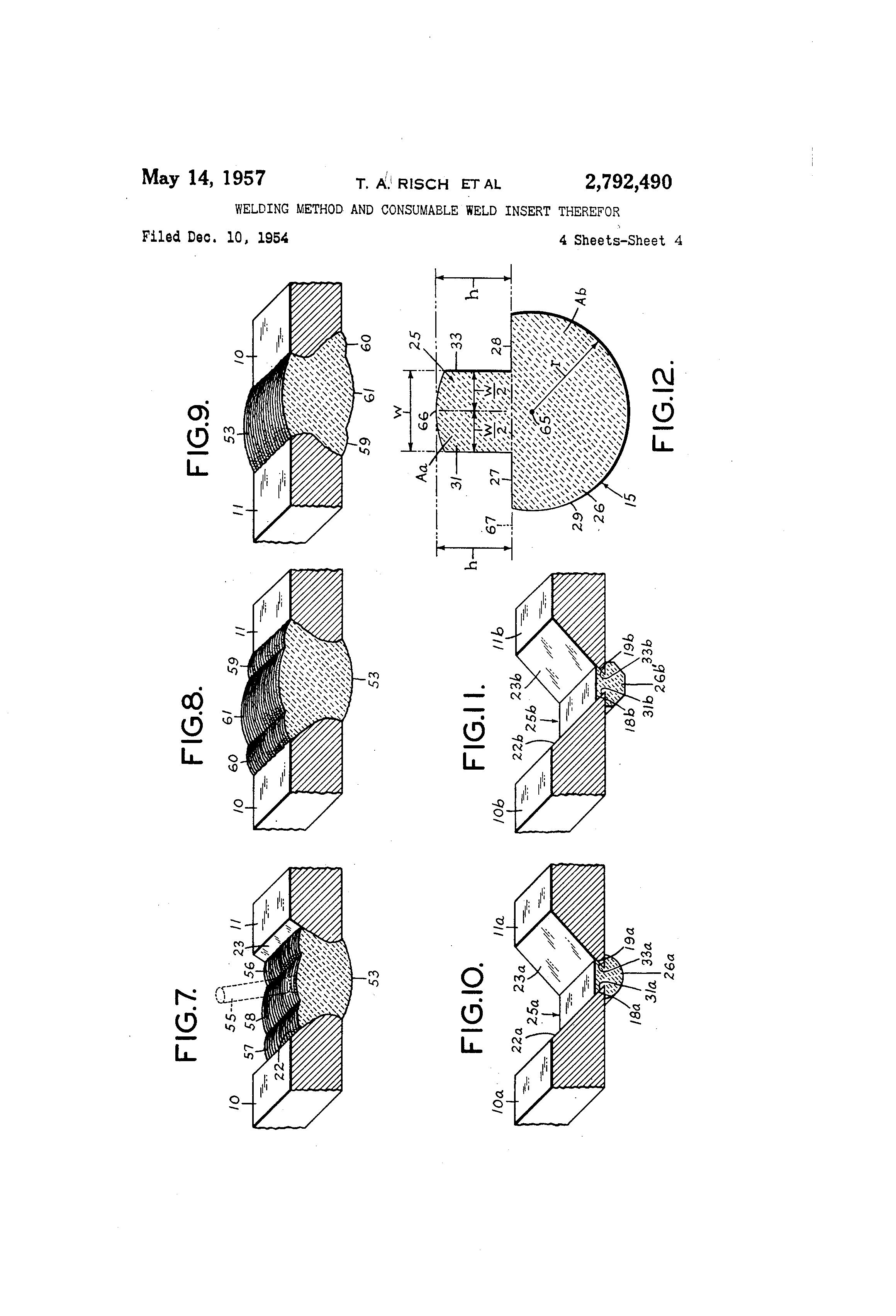

Using the "TIG" process, once the root pass has been completed, the internal inert gas purging should be maintained while the second pass is completed with filler metal. Gas purging may be eliminated after root pass using MIG, ARC or other processes for second and subsequent completion of the welded joint.

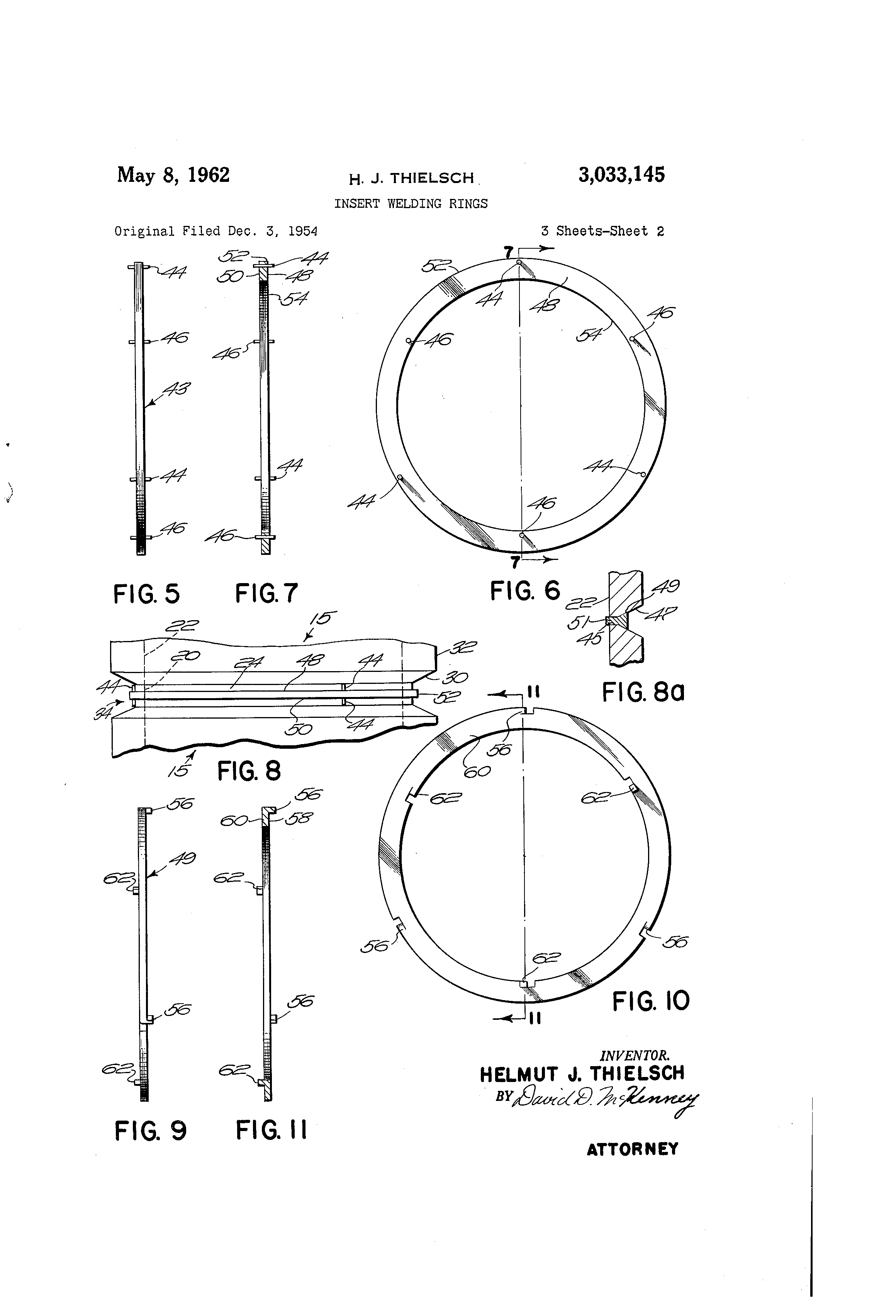

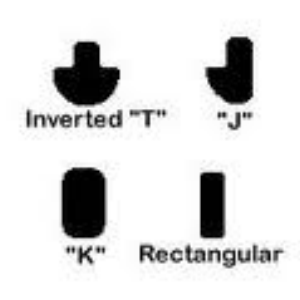

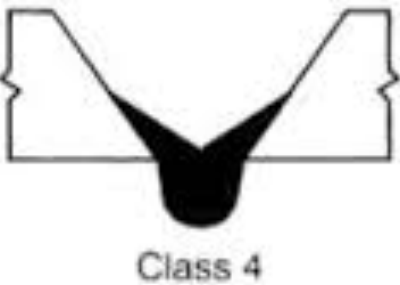

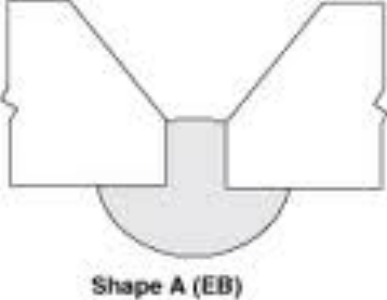

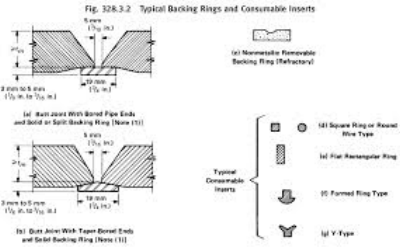

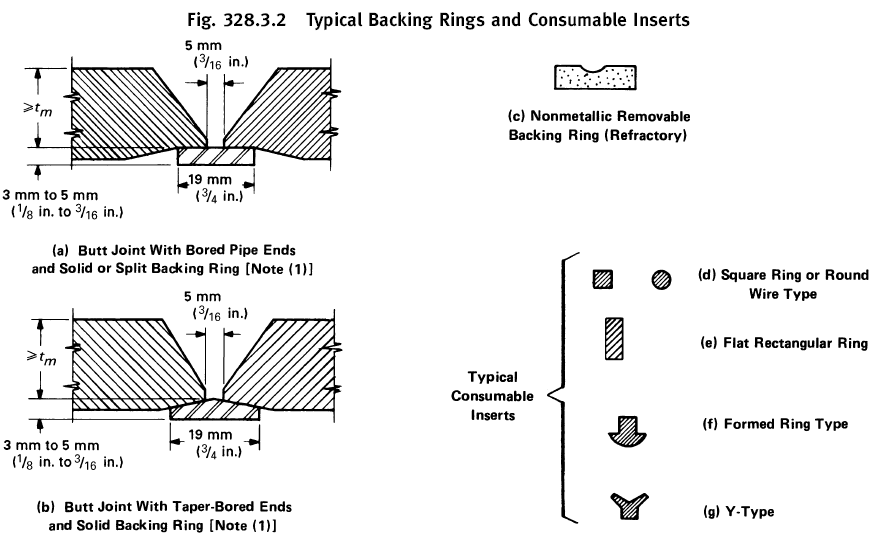

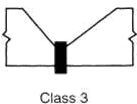

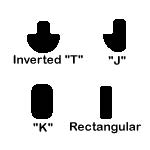

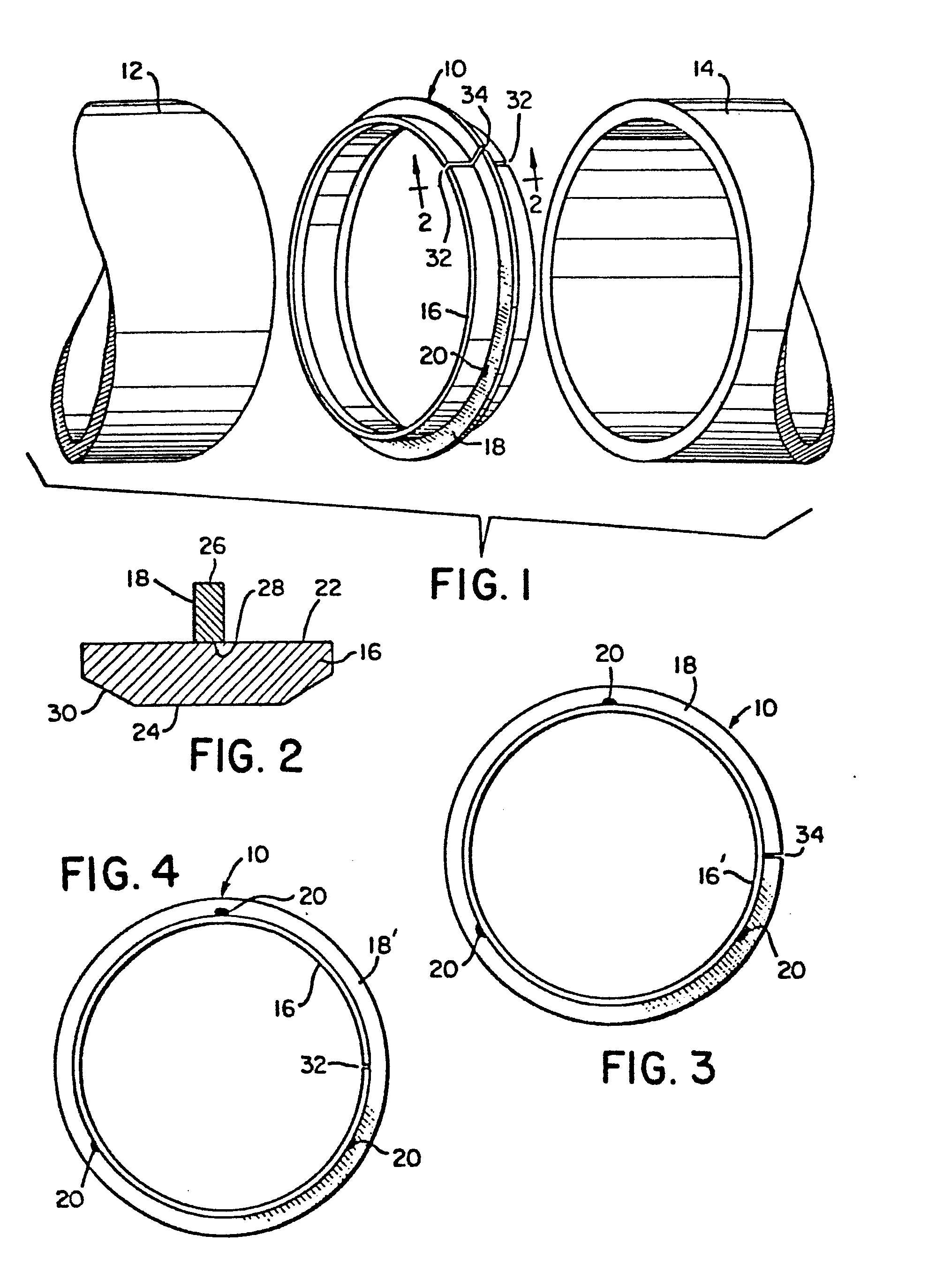

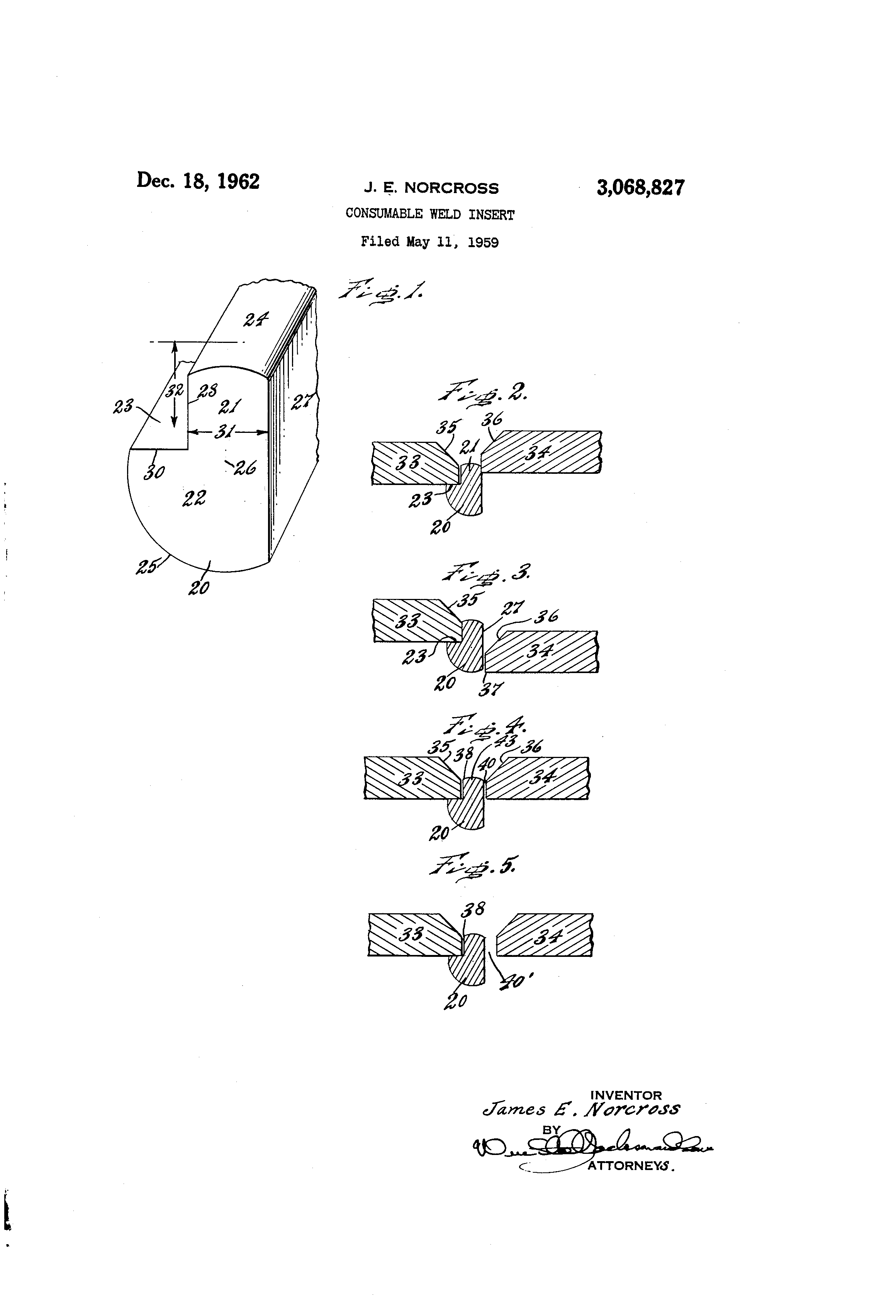

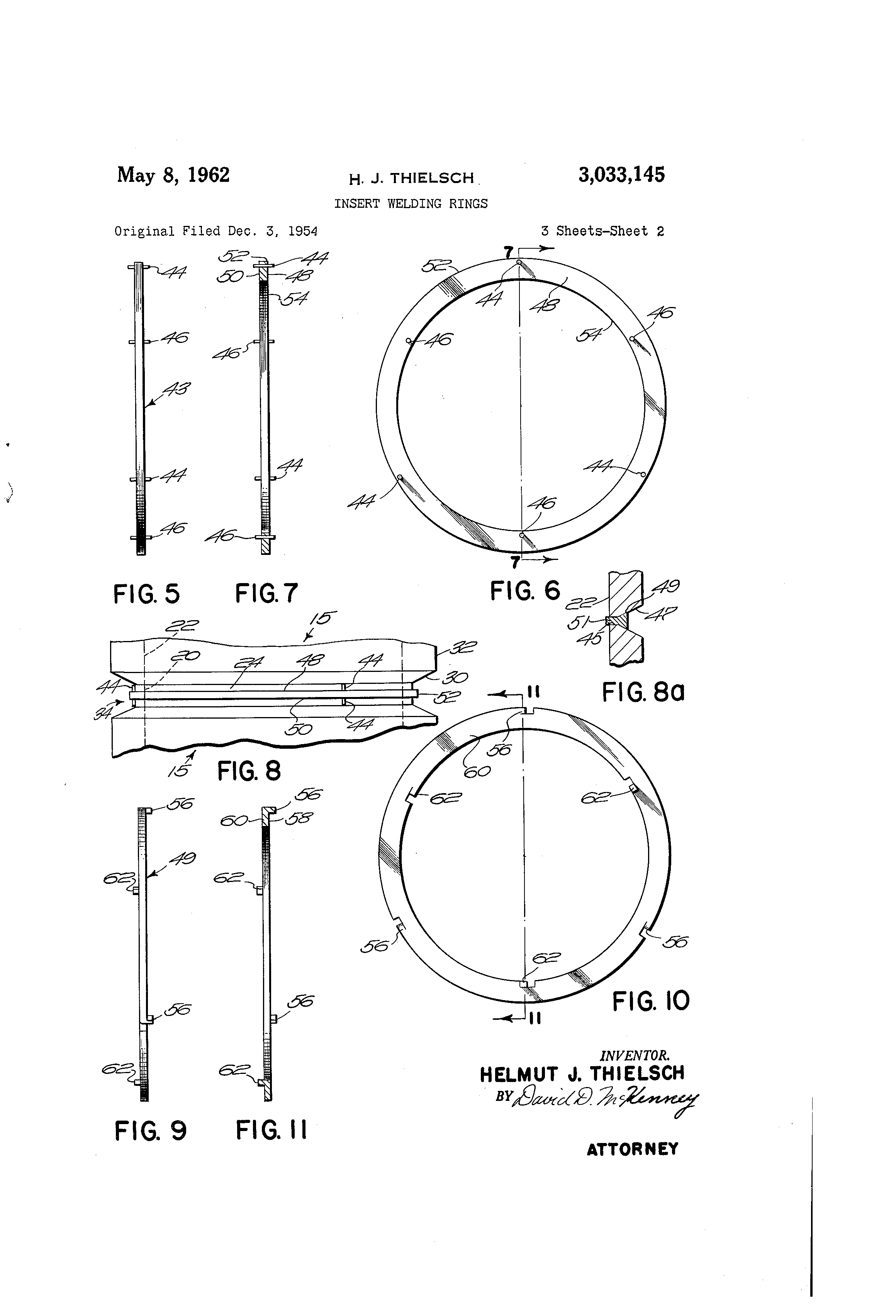

Typical end preparations include, but are not limited to, the "J" and "V"-Groove in accordance with ASTM, AWS, ASME or MIL specifications.

SPECIFICATIONS: All shapes are manufactured in accordance with AWS 5.30, ASME 5.30 and MIL-I-23414. MATERIAL SPECIFICATIONS:All shapes are manufactured in accordance with AWS 5.30, ASME 5.30 and MIL-I-23414. QUALITY CONTROL:All materials are manufactured under Robvon's Quality Assurance Program, 10CFR50, and are qualified for nuclear work.

GENERAL MATERIALS AVAILABLE: MATERIAL DESIGNATION FOR WELDING: Ms 1 (E70S2)Carbon Steel, Ms 2 (E70S3)Carbon Steel, 5024 to 6 Percent Chrome Moly, 5151¼% Chrome ½% Moly, 5212¼% Chrome 1% Moly, 308 & 308L Stainless Steel, 304 & 304L Stainless Steel, 302 Stainless Steel, 309 & 309L Stainless Steel, 316 & 316L Stainless Steel, 347 & 348 Stainless Steel, 6ANiCrFe-6, 60 Monel NiCu-7, 61 Nickel Ni-1, 62 NiCrFe-5, 67 Cupro Nickel, CuNi, 82 Inconel, NiCr-3

NOTE: OTHER MATERIALS AVAILABLE UPON INQUIRY

http://www.imperialweldringcorp.com/consumable_inserts.htmhttp://www.thefabricator.com/article/aluminumwelding/welding-aluminum-pipinghttp://www.dtic.mil/dtic/tr/fulltext/u2/a452009.pdfhttp://cstools.asme.org/InterpretationsPDF/BPVC-IX%20Interp_Stnd-59_2008.pdfThere's more but, I'm going to stop here and edit tommorow.

Respectfully,

Henry