After four and a half years of ownership with little to no problems from my Sa250 I decided it was time to do some maintenance. Since owning it I've had the starter rebuilt, put a carb on it and plugs and wires(several), then your standard oil changes, battery along with the selector knobs. For what this machine has done it has been awesome.

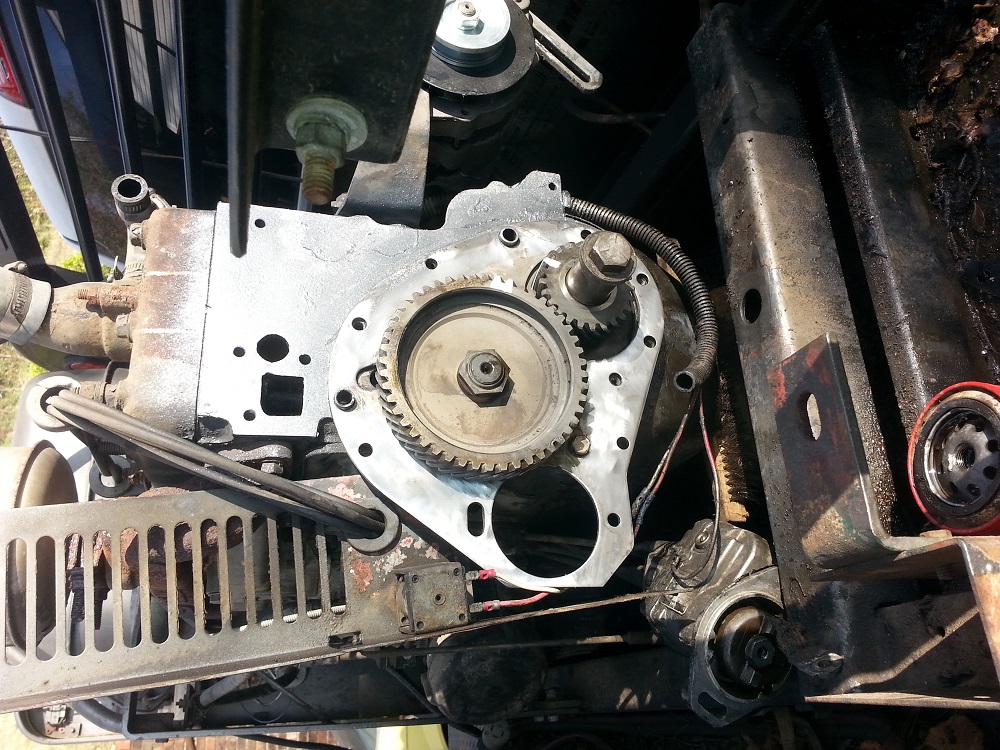

With some time down I decided to plug the Valdeez, a.k.a., my Sa250's oil leaks. Rear main, front crank seal and others that have kept my truck well lubricated. Yesterday finished up the rear main and all related gaskets, oil pan gasket on the bottom end. Crank shaft looked good on the main, could see cross hatching on the cylinder walls. Once I was done rolling around on the shop floor I moved on to reseal the rocker box cover. The front end was torn down and resealed on the truck a few days prior but was lacking the front crank seal. So pulled crank pulley from freezer(0 degree's for 2 days) and installed "speedy sleeve", new seal and threw on some German torque.

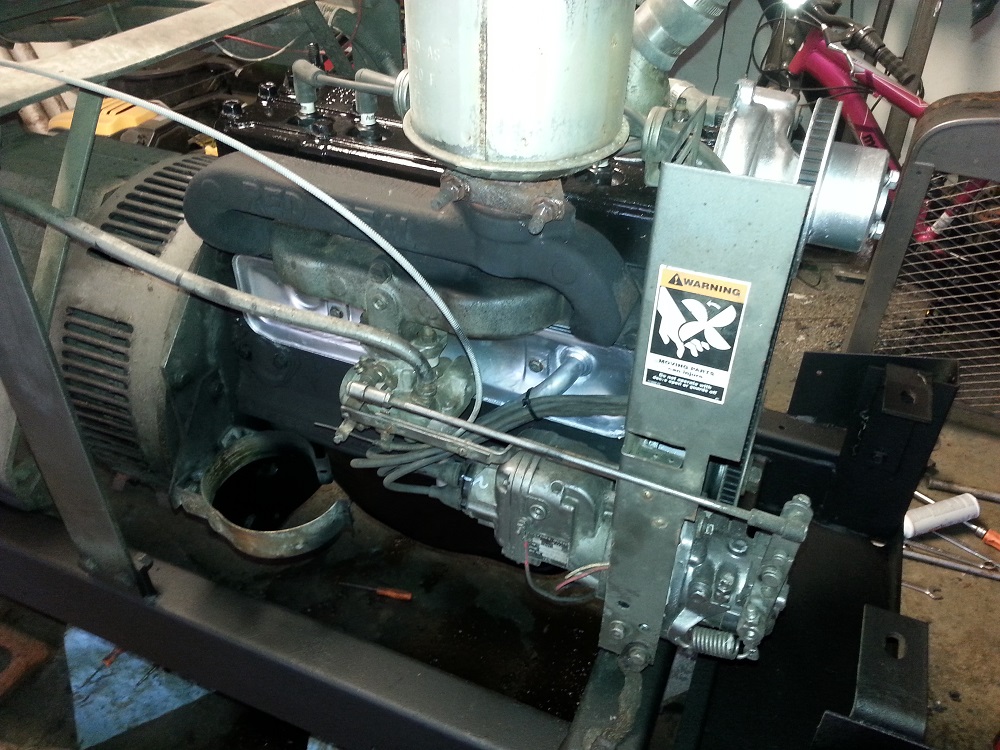

Moved up, pulled the head, cleaned up the block, head, added some purty high heat paint to oil pan, block, front end, head, water pump, can't have it looking like dookie!! Got the governor timed, magneto timed, all new gaskets throughout. Radiator had a leak so had it completely refreshed for $90, hoses connected and all the mechanical work is done! Going to add fluids today and crank her up to check over for any leaks, issues, set timing and check governor settings.

Moving on to the body shop now. Have cleaned up the frame, battery box and decided to go with 3M undercoating on the lower frame, battery box area. I liked the look, simple black plus protective against the elements as well as easy to repair, just spray on some new coating and move along! Radiator grill sanded down, primed and first coat of paint on. Next is fabricating the new doors. Absolutely hated everything about the swinging doors so have decided that I want to do stationary doors over the generator side and sliding doors on the engine side. At least this will give access to the important stuff without tearing down the hole machine, i.e., oil filter, oil level, plugs, wires, alternator and so on. Once all that is done, have to prep hood, doors then paint.

I'd like to say this has gone off without a hitch but never have seen the inside of a Continental F163 so each one of these creatures is different. While installing my upper rear seal holder(new seal is a bit more snug than the old seal) I broke the aluminum piece. Lucky for me I have a spare F162 and a spare F163! Removed rear main to hopefully give a little space but even then you must have patience to install it, at least on my machine is how it worked out.

Have several more days but seems my clients have got word that I'm doing this, phone is exploding with phone calls wanting me to come out and weld. So much for December off!!!