Laser-generated surface structures create extremely water-repellent metals

January 20, 2015 University of Rochester - "Meliora"

Super-hydrophobic properties could lead to applications in solar panels, sanitation and as rust-free metals

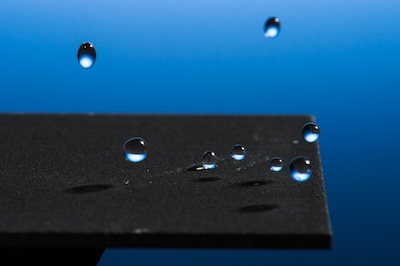

Scientists at the University of Rochester have used lasers to transform metals into extremely water repellent, or super-hydrophobic, materials without the need for temporary coatings.

Super-hydrophobic materials are desirable for a number of applications such as rust prevention, anti-icing, or even in sanitation uses. However, as Rochester’s Chunlei Guo explains, most current hydrophobic materials rely on chemical coatings.

In a paper published today in the Journal of Applied Physics, Guo and his colleague at the University’s Institute of Optics, Anatoliy Vorobyev, describe a powerful and precise laser-patterning technique that creates an intricate pattern of micro- and nanoscale structures to give the metals their new properties. This work builds on earlier research by the team in which they used a similar laser-patterning technique that turned metals black. Guo states that using this technique they can create multifunctional surfaces that are not only super-hydrophobic but also highly-absorbent optically.

Guo adds that one of the big advantages of his team’s process is that “the structures created by our laser on the metals are intrinsically part of the material surface.” That means they won’t rub off. And it is these patterns that make the metals repel water.

“The material is so strongly water-repellent, the water actually gets bounced off. Then it lands on the surface again, gets bounced off again, and then it will just roll off from the surface,” said Guo, professor of optics in the University’s Hajim School of Engineering and Applied Sciences. That whole process takes less than a second.

The materials Guo has created are much more slippery than Teflon—a common hydrophobic material that often coats nonstick frying pans. Unlike Guo’s laser-treated metals, the Teflon kitchen tools are not super-hydrophobic. The difference is that to make water to roll-off a Teflon coated material, you need to tilt the surface to nearly a 70-degree angle before the water begins to slide off. You can make water roll off Guo’s metals by tilting them less than five degrees.

Here's the link to the web page:

http://www.rochester.edu/newscenter/superhydrophobic-metals-85592/So, the question is this... Are these new metals, or are they really just a new method of metal surfacing engineering/Coatings technology developed in order to alter a characteristic that can be found in most metals? And can this same type of surface treatment be applied to other materials besides metal - like concrete, papers, fabrics, painted surfaces etc.?

I guess we'll all have to wait and find out how universal this really is with respect to Materials Science in general and uncommon applications. Very interesting nonetheless.

Respectfully,

Henry