Between gas shielding composition, welding parameters, and other factors involved (and this is a question as I am not that versed in Aluminum period and especially outside GTAW) I didn't know you could truly 'short arc' aluminum?

And as has been said many times on this forum, why would you want to and how many applications would there be for it?

I tend to agree with others even though my observations are based primarily upon carbon steel applications, there are a good many latest, greatest, fancy, over the top gadget packed machines available anymore that you need an electrical engineers degree and 6 months worth of training to operate. Companies buy them expecting this vast improvement in production and quality and then the guys won't use them, at least with all the gadgets working correctly, because they don't like change, don't like giving up personal control, don't like everyone else knowing what they are actually doing to get the job done (job security) and much more, so the machine sits in a corner or on top of a shelf (out of sight- out of mind) and goes to waste.

The key is generally training and time. Don't expect immediate results. Encourage the time it takes to get it right and figure out how to use it. Even send someone to special training at a school or at least the manufacturer (I wish someone would do that for me and computers, oh, wait a minute, I am that someone. I need to send myself for training).

He Is In Control, Have a Great Day, Brent

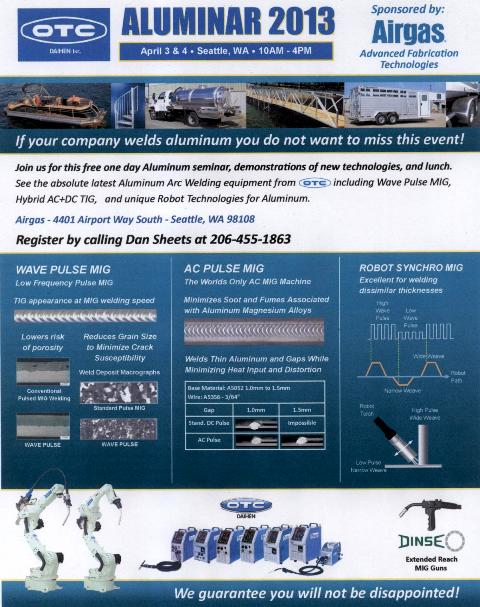

I only hope that there's no sacrifice in quality with AC GMAW compared to VPPAW just so one could increase deposition rates and arc on time...

I only hope that there's no sacrifice in quality with AC GMAW compared to VPPAW just so one could increase deposition rates and arc on time...

Here comes the preheat Aluminium debate again...

Here comes the preheat Aluminium debate again... You don't preheat heat treatable Aluminium.

You don't preheat heat treatable Aluminium.