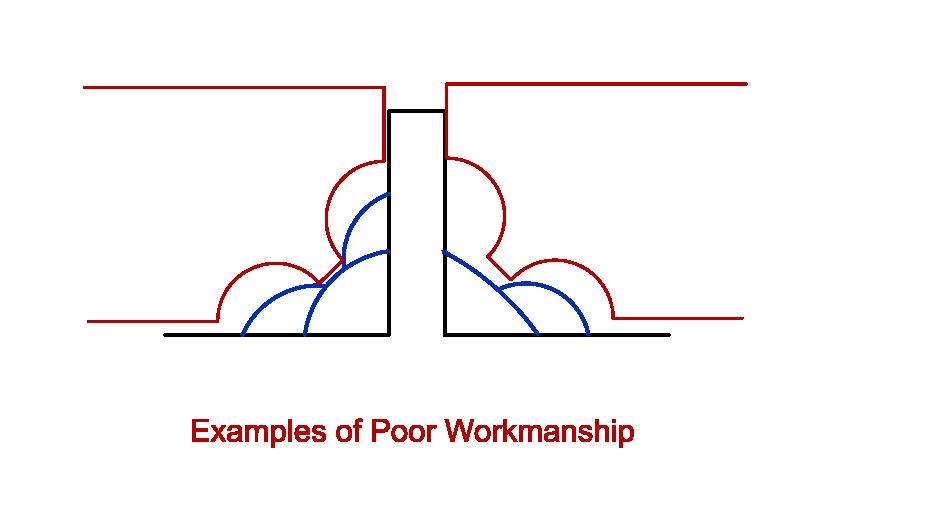

Please excuse my poor drawing, the piece I have isn't as extreme as the picture. D1.1 2010 A36, 045 flux cored wire. As an in-house inspector at the end of the day I have the authority to reject a weld if I don't feel it is to shop standards. Which is what I'll be doing this time but I want to ask if anyone can help back this up per D1.1?

"T" joint 1/2" fillet weld 3 pass flat with 045 flux cored wire is what we're going for. From my experience it's fairly simple root, then 2 cap passes. To myself it's always been common sense that the 2 cap passes fully cover the root. Then I ran across this.

I can see all passes including the root. The toes of the cap passes bring it to the proper size. The only way I can find where I could reject it per code would be if I check the concavity of the weld and it failed. If it falls within table 5.10 is there anywhere I can reject it per the code? Thanks I hope there is enough there to give an idea.