By 803056

By 803056  Date

Date 11-07-2015 23:55

Edited 11-09-2015 05:39

I had hoped the original poster would get off his butt and tell us exactly what he meant. But, what the hell, garbage in, garbage out. One really needs a sense of humor to play in this sandbox.;)

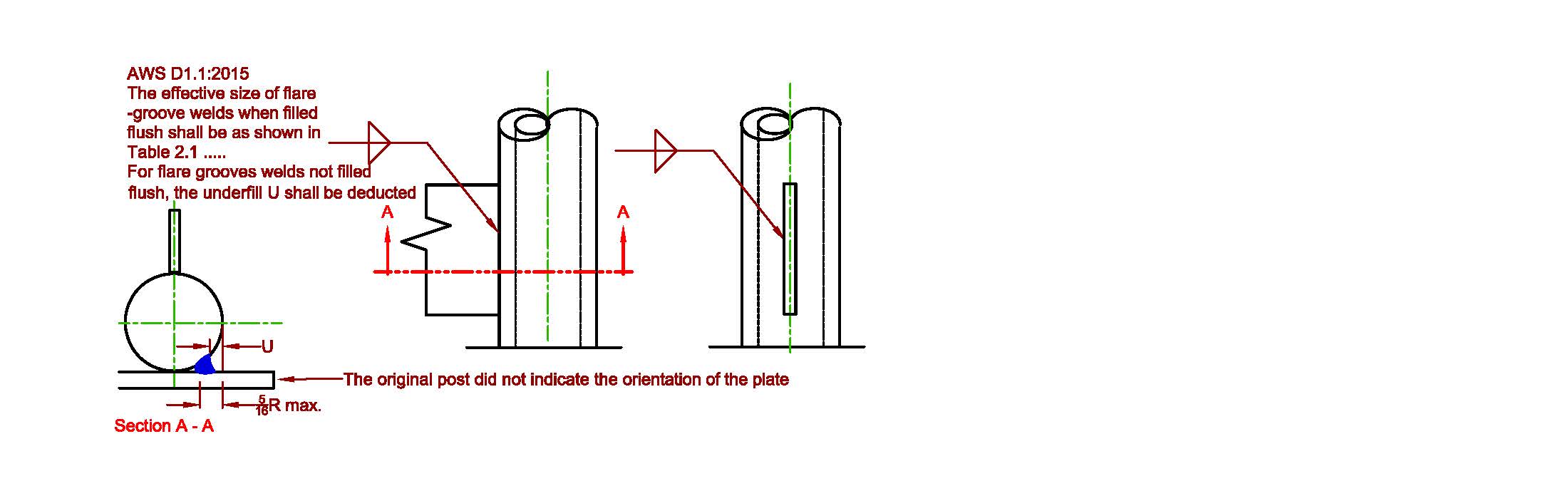

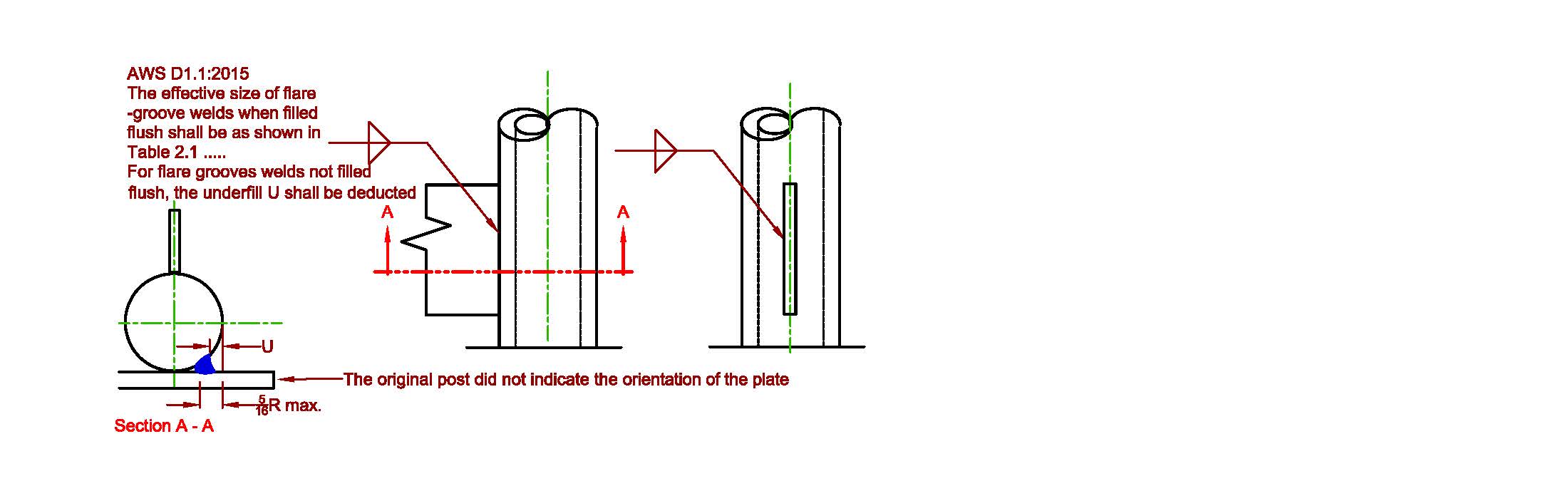

I assumed we were looking at a plate butted up to the pipe as depicted in the sketch. I also expanded the sketch to include section A-A which depicts both my configuration and the configuration many of the responders assumed was applicable.

I included the size limitation contained in clause 2. The size of the flare groove weld assumes the weld is flush with the round edge (pipe). The size of the weld is reduced by the under fill "U" dimension. So, if the pipe lies on the plate, a flare bevel groove is appropriate. The weld size can be less than 5/16 x R as long as the minimum size requirements of Table 3.5 are met.

However, if the plate is butted against the pipe, as I initially depicted, there is no way it can be considered to be a flare bevel unless the edges of the plate are intentionally rounded. If the plate is rounded to a radius T/2, where T is thickness of the plate, the size of the flare bevel groove weld would be limited to (5/16 x T)/2 provided the welding process is either SMAW or FCAW-S. Assuming the edges of the plate are rounded and the plate is 1/2 inch thick, the maximum weld size permitted (prequalified) per side would be 0.078 inch. That would be less than the minimum permitted by Table 3.5, i.e. a violation of the conditions for prequalification. That would support the notion that fillet welds are applicable. Figure C-4.1 also supports the configuration I depicted is a fillet weld.

What I didn't include was the plate welded to the end of the pipe as it would appear if it was used as a column. I figured that configuration is a "no brainer."

Al