Mcostello, you might enjoy reading some of the past discussions on the subject of diffusible hydrogen we've had.

Monatomic hydrogen (single atoms) can and does diffuse through the atomic lattice. The hydrogen collects at sites referred to as hydrogen traps. The hydrogen traps are often discontinuities, grain boundaries, etc.

This was something I found confounding when I was first introduced to hydrogen in welds, the affects, and preventive measures. The professor did a great job of putting the whole thing into context. As he put it - thick of yourself on a football field. The four largest beach balls you can find are positioned at the corners of the field. A small glass marble (like the one's kids used to play with) is located on the 50-yard line. All the empty space between the beach balls (representing iron atoms) and the small marble (representing the hydrogen atom) represents the space in the lattice structure. All that empty space gives the hydrogen plenty of freedom to move (diffuse) from one location to another.

The rate of diffusion is related to temperature. The higher the temperature, the greater the rate of diffusion.

Now, what happens to the hydrogen is interesting. Over time the hydrogen atoms diffuse to the surface and effuses (escape) into the atmosphere. In which case nothing bad happens. There are a couple of working hypothesis in the wonderful world of metallurgy and welding. One, and probably the oldest conjecture is some hydrogen can team up with other hydrogen atoms to become molecules. The molecules occupy a larger volume and exerts a stress on the atomic lattice. If the lattice lacks ductility, it can fracture. Another hypothesis is when there is an abundance of carbon, as in the case of a martensitic microstructure (iron saturated with carbon) the hydrogen is thought to combine with the carbon to form methane gas. The molecule of methane is much larger than the diatomic hydrogen, thus exerts a much greater stress on the bonds and tends to cause cracking (hydrogen assisted cracking, cold cracking, delayed cold cracking, under bead cracking, etc.).

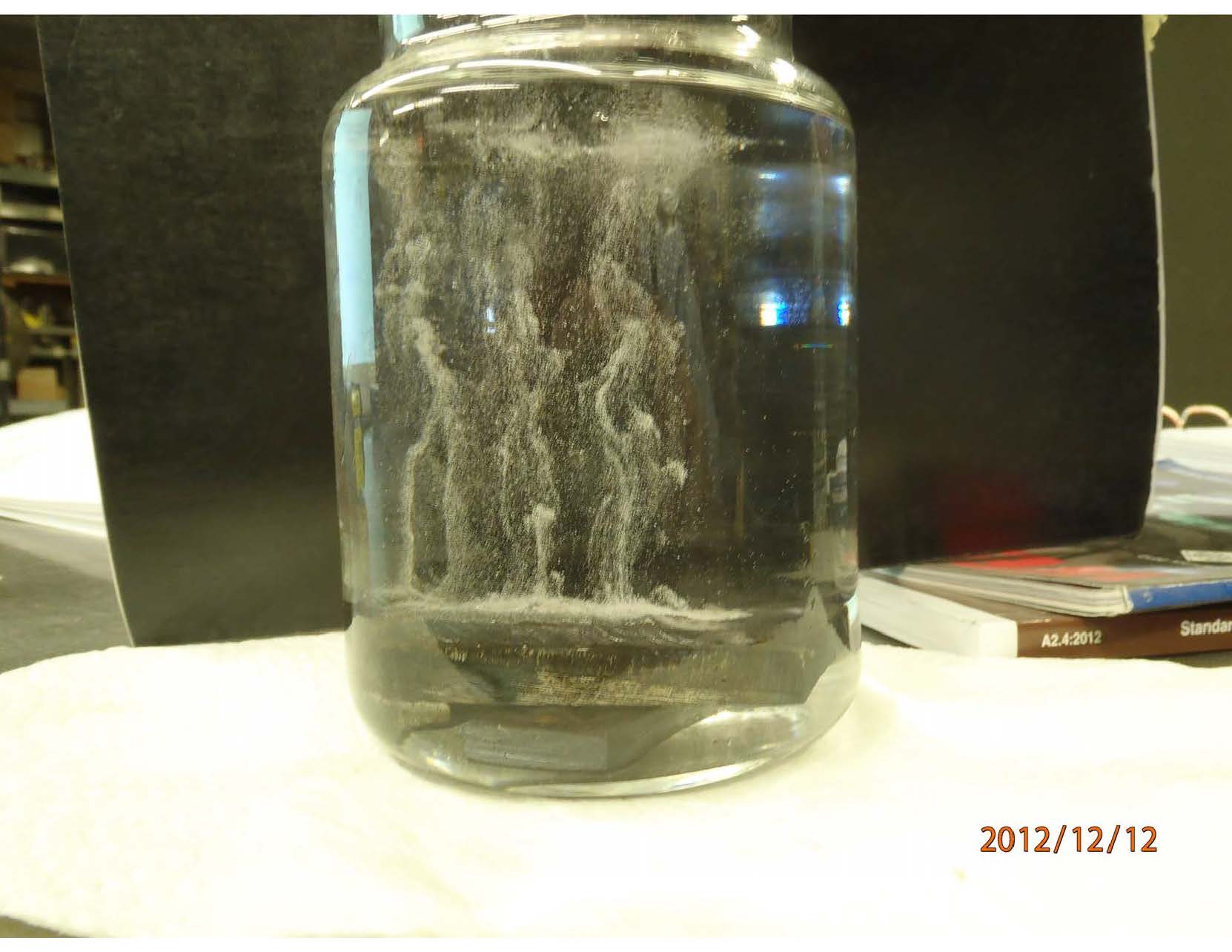

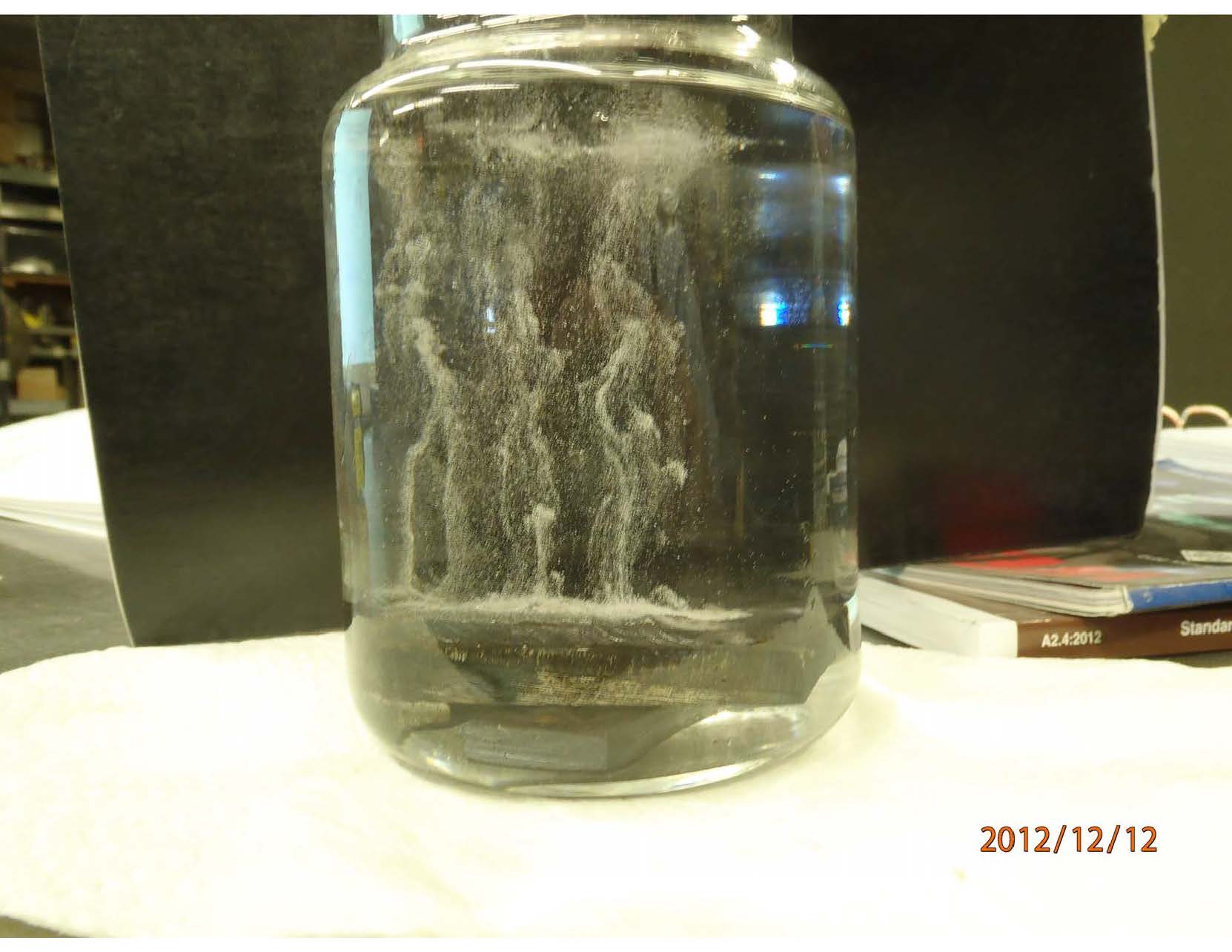

One can see the hydrogen effuse from the surface of weld bead. There are examples of the experiments on You-Tube. I have a file that shows the hydrogen coming out of a weld bead. I will send it to you if you send me your e-mail address. I don't believe I can attach it to a post. I can attach a photograph of an earlier experiment I did for an AWS Section meeting several years ago. The interesting thing is the sample off gases (hydrogen) for upwards of twenty hours.

Hope that helps. This is exactly why the latest edition of D1.1 causes the hair on my neck to stand up on end. The statement that it is permissible to weld on surfaces with residual contamination such as water, oil, grease, etc. is a crock of bull crap. It flies in the face of common sense. I used to think that the members of that committee had an abundance of common sense. My faith in D1.1 is shattered like a skull hitting the pavement after falling from the twentieth floor of a high rise. What other clauses of D1.1 should the user ignore? Some of it, all of it, or just that one clause?

I proposed that the Certification Committee not use D1.1:2015 for the CWI examination. My proposal wasn't accepted. Maybe because I wasn't there to make my case. One must not throw stones at the sacred calf or jeopardize the golden goose.

Best regards - Al

Hello Paladin;

Actually your hydrogen "bake off" reminds me that there is a procedure called a "Hydrogen Bake Out". The completed weldment is heated to at least 550 degrees F and held at temperature for around six hours. The steel expands when heated, increasing the distance between the adjacent atoms and allowing the hydrogen to escape more easily.

I am sure the Ideal Gas Law comes into play. As the weldment is heated, the partial pressure of the gas increases and "forces" the hydrogen to effuse more readily into the atmosphere that is at a lower pressure relatively speaking.

So, you have a couple of mechanisms at play, all encouraging the hydrogen to leave the atomic lattice and reduce the probability of delayed cold cracking.

While aluminum may age naturally and gain strength, I don't recognize it as a strengthening mechanism in carbon and low alloy steels. In the case of aluminum, the strengthening mechanism requires the aluminum to be heated to a high temperature to allow the alloying elements to go into solution and form a supersaturated solution when the aluminum is quenched. The supersaturated system is not stable. At room temperature (or slightly above) the solubility decreases (compared to the solubility at high temperature) and the excess alloying elements form small clumps within the atomic lattice (interstitial) thereby straining and distorting the lattice. Anything that distorts the atomic lattice makes the metal stronger and harder.

A similar mechanism is used to harden and strengthen precipitation hardenable stainless steel. The mechanism is triggered by heating the quenched stainless to get the supersaturated alloying constituents to clump within the atomic lattice. Starting to sound similar to the age hardened aluminum?

Best regards - Al