Thanks for that Al. The fluid coming into contact with the material is a glycol mixture at about 10psi. I understand that the best warm and fuzzy will come from some full section compare and contrast tensile pulls. However, in theory, if I face the weld back say past the fusion zone into the fine grain zone of the HAZ and re-weld, wouldn't all of my alloying elements still be present and the re-liquidfication of all the remaining HAZ through the same original welding process produce a grain structure in the weld similar if not the same as the original weld with all alloying elements present? The HAZ of this orbital weld is vary narrow. I'm almost positive that we are facing back past the HAZ, but overall dimension is a huge concern so they can only be reworked once. I am just being inquisitive about the what if's ya know.

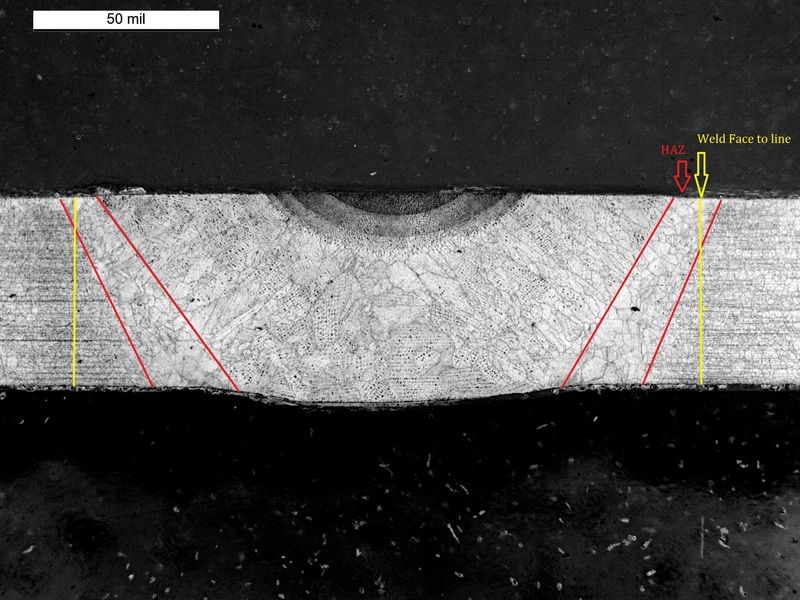

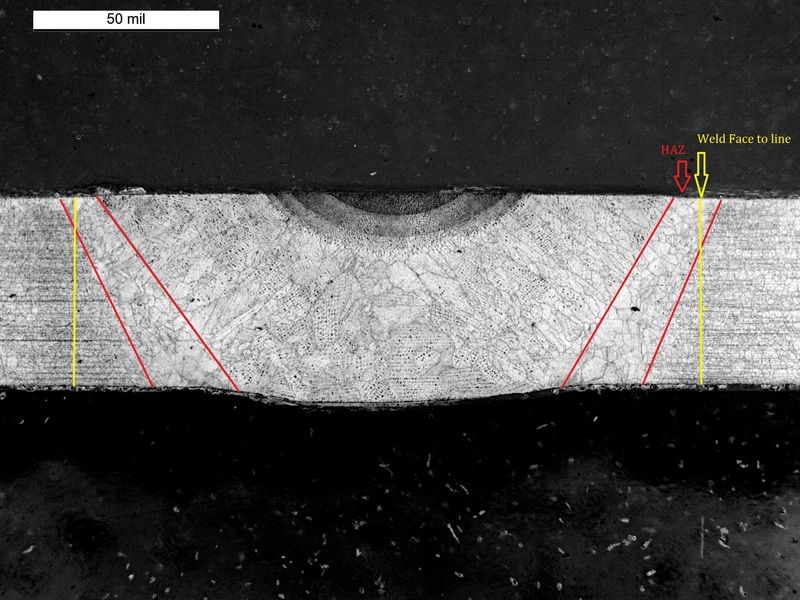

Here's a macro of the weld and a what if scenario. The dark arches in the center of the weld are the tail out pulses from the orbital welding process.

Kix