I am reposting the post below from the NEW AWS forum in order that a forum member (Al) will be able to post a reply that includes a graphic presentation (thank you in advance Al):

I am putting together some WPSs using Chapter 3 of D1.1-15 and its prequalified data.

When it comes to welding parameters, in Table 3.6 (Prequalified WPS Requirements) for FCAW it says for Maximum Current: "Within the range of recommended operation by the filler metal manufacturer."

The procedure will be for .072 Coreshield 8. ESAB provides the following:

WELDING PARAMETERS

Data from ESAB Welding Filler Metal Data Book (Feb, 2012)

Diameter Arc Volts Wire Speed Amps Polarity

.072" 18.0 100 IPM 160 DCEN

.072 19.0 130 IPM 205 DCEN

.072" 20.0 160 IPM 230 DCEN

.072" 21.0 190 IPM 260 DCEN

.072" 22.0 220 IPM 275 DCEN

Table 3.7 (Prequalified WPS Variables) under Process Parameters states the following regarding amperage: ">10% increase or decrease", regarding voltage: ">15% increase or decrease", and regarding WFS: ">10% increase or decrease".

I am not sure how Table 3.7 should be applied to the 5 lines of factory data. The WFS for example has over a 100% swing in range.

So what is the proper way to list the minimum to max amperage allowed on one WPS? Would it be acceptable to say "160 to 275 amps", or if I wanted to, could I go 10% below 160 and 10% above 275 and make it "144 amps to 302 amps"?

Or would the +/- 10% have to be applied line by line to each of the 5 factory recommendations above? Same question about voltage and WFS.

Or would the right answer just be to copy / paste the factory recommendations as a chart like I did above and call it done? I am not crazy about that as the welder would not know, for example, what the authorized variance was on voltage for a given WFS.

Given my personal experience with the wire, and the fact I like the latitude to produce best results, I would prefer to simply list the parameters like this if it is acceptable: Voltage 18 - 25, WFS 100 IPM to 220 IPM, and Amperage 160 - 275. Would that be in line with the D1.1 requirements for using factory data in a prequalified WPS?

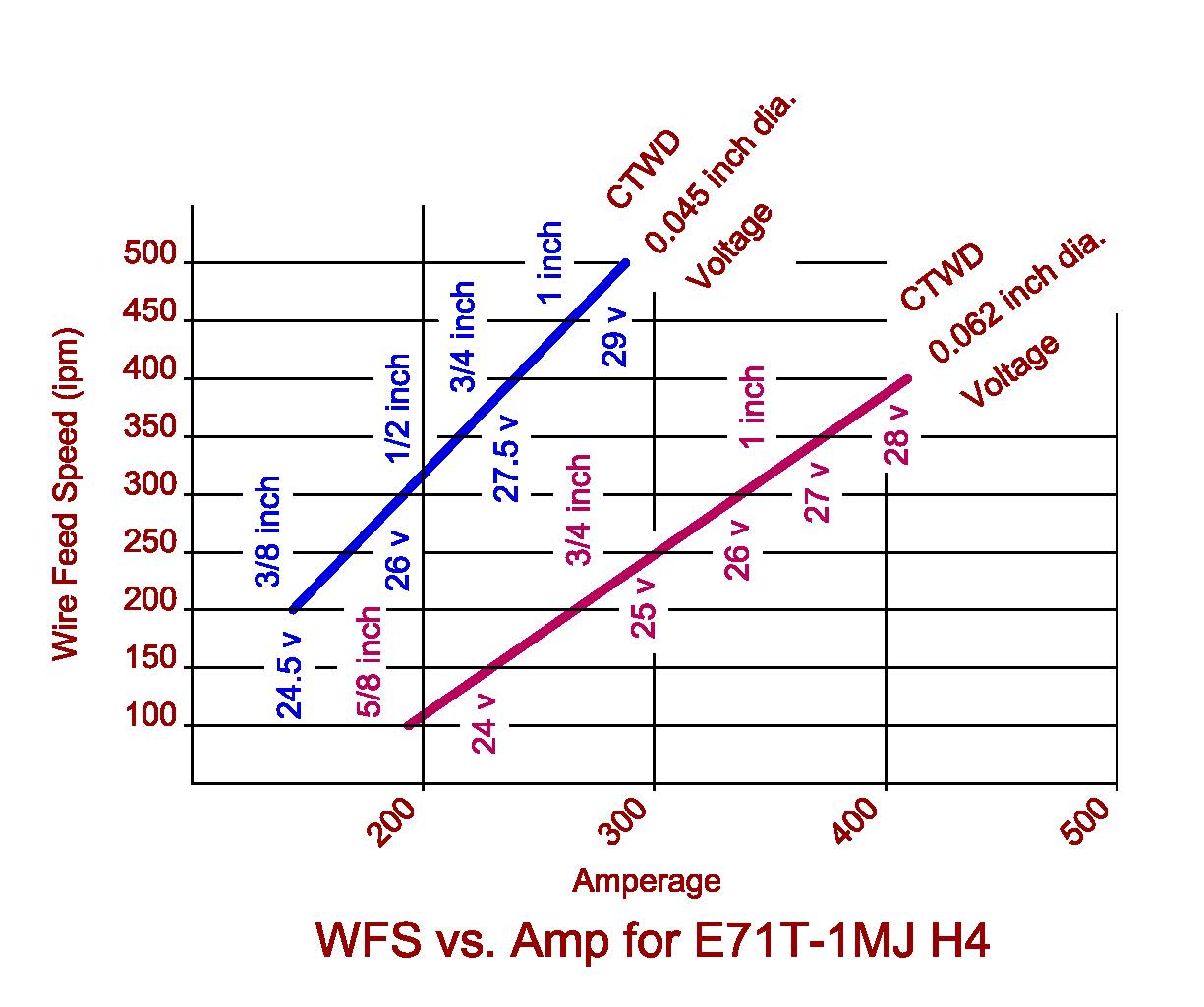

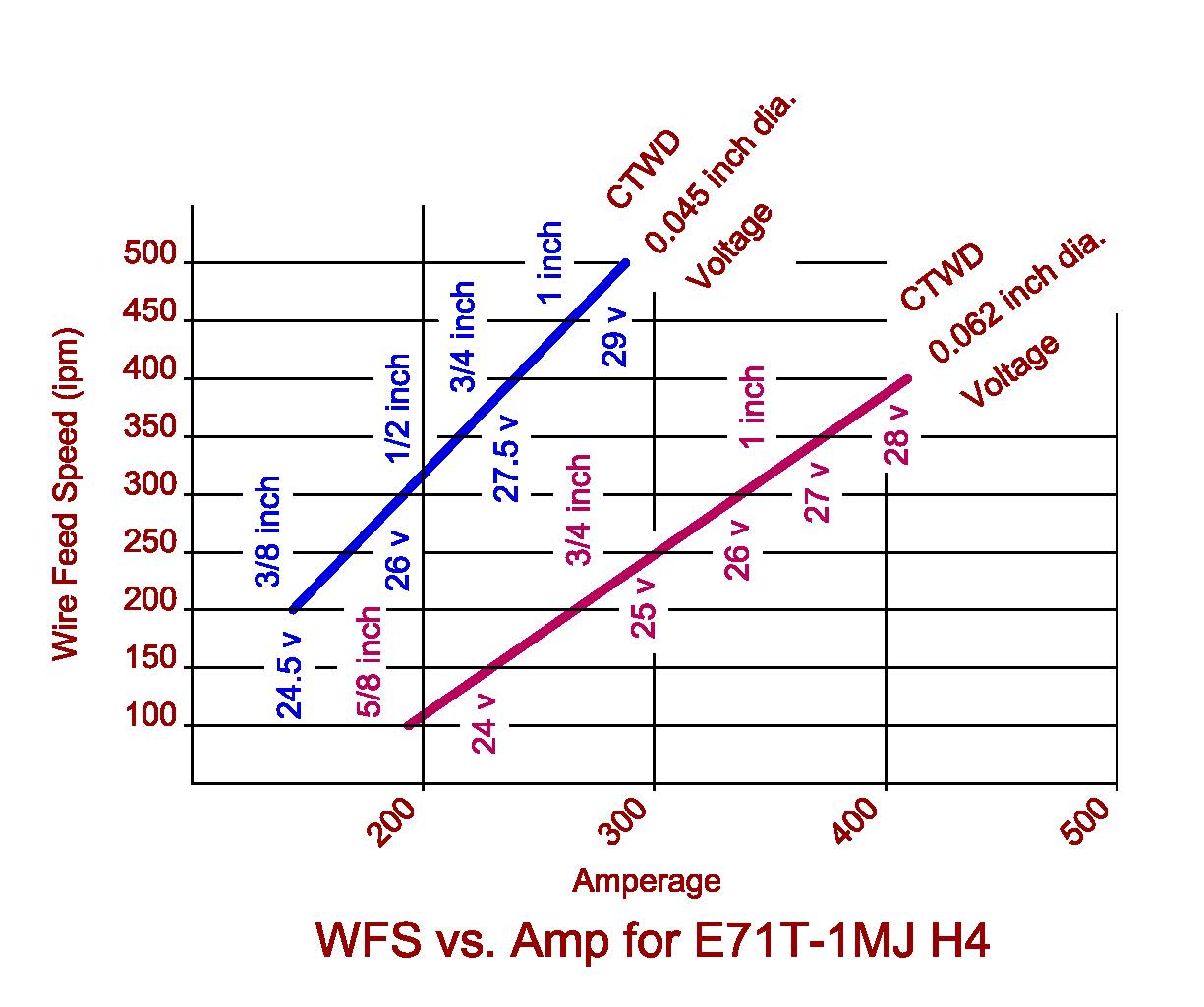

I use a graphical presentation.

Depending on the position, the thickness of the material, or the weld type, you can narrow the range by showing just the range you want the welder to use.

I have had very favorable responses from the welders that use these graphs. It is easy for them to select the appropriate parameters from the graph. You might have to show them how to use a graph, but it is easy enough once they have been shown.

Select the diameter of the electrode. Dial in the wire feed speed for the mid-range of the wire feed speed, move across the graph horizontally to the appropriate line representing the electrode diameter, pick out the voltage and contact tip to work distance, and you are ready to strike an arc. If the welder is using the appropriate electrode extension, the amperage will be right on target.

Let's try one. Using 0.045 inch diameter electrode, start with a wire feed speed of 350 inches per minute. Moving horizonally, the voltage should set to 27 volts, the CTWD would be 3/4 inch, and if everything is set properly the amperage should be about 220 amps. If the welder is holding the gun too far away from the work piece, the current will be lower. If the gun is too close to the work piece, the amperage will be higher.

The shielding gas used will affect the arc voltage. It is best to use the shielding gas recommended by the manufacturer. If you are writting a prequalified WPS you have to use the same gas as recommended by the manufacturer.

Switching from one trade name to another or switching manufacturers will usually require the construction of a new graph.

Best regards - Al

Thanks Al, I like that. I can see how a welder would find that useful.

Blaster,

Al hit the nail dead on

Depending on the position, the thickness of the material, or the weld typehe did miss a few, but he is an inspector

20 to 21 volts is my choice

and also ESAB choice

that is the new guide 2016

but many other things to think about

the welder has to have some input

about how they run it and the machine

just imho

sincerely,

Kent

edit btw NO GAS.........self sheild

If I'm checking paperwork, I wouldn't accept your final proposed parameters, as they violate the +/- ranges in Table 3.7

If I was writing WPS's with factory data, I'd pick a row of parameters that works for base metal thickness, position, welder skill, etc. and apply the +/- to those figures

If you use 21v, 190 IPM, and 260A my ranges would be as follows:

Mathematically calculated

Volts 17.85 to 24.15, IPM 171 to 209, Amps 234 to 286

As used on WPS (little bit of rounding and whatnot here to get easy to set numbers)

Volts 18-24, IPM 175 to 210, Amps 235 to 285

I think the calculations provided by Al and the ranges included in Clause 3 are important. We need to know with confidence where our welding data comes from.

But I don't think it is always the best option to apply the full ranges to a production WPS.

The object is to make good consistent welds. The object is not necessarily to give the welder the maximum amount of room because "he knows best"... I find that is rarely the case.

Giving a welder 100 amps to "play with" means over 3 lbs an hour deposition potential difference between operators !

I think a good WPS looks at the work to be accomplished and provides a narrow range of parameters that take into account things like: length of work leads, minor differences in CTWD, mill scale, gaps in fit-up.

I really do think that for the electrode wire given (Coreshield 8) that a WPS that is inclusive of base metal thicknesses from 3/16" to unlimited thickness and all positions can easily be written with a range of 30 IPM, 40 amps, and 2 volts with a note that "current is approximate and not controlled by the welder" I like holding the WFS a bit tighter "within the range" than the current... The WFS is the engineering control in my view, where the current is a compliance control, if that makes any sense.

So yes... To the calculations to determine the maximum ranges. But write the WPS with tighter ranges and with process control, quality, homogenous visual appearance, and productivity in mind.

If two welders are working side by side, doing the same joints, one at the top of the D1 allowable range and the other at the bottom, their weld profiles will look completely different, which in turn will draw the attention of 3rd party inspectors. The high parameter welder will make that fillet at 15 IPM travel speed and the low parameter welder at 10..... Not a controlled project.

Totally agree

I put the max of what the code would allow, and used a factory parameter from the list. If I was reviewing the WPS to be used on my job, I would have to accept it as IAW D1.1

If I was writing the WPS, Id snug way down on the volts and WFS, and I always like to note that the amps is not a "settable" parameter.

Fun experiment: check the amps on a CV machine with a 1/2" ESO and then with a 1" ESO sometime. Its fairly surprising how much change you get, which indicates that you may want to snug down on ESO, and WFS

Thank you...

I get on a tangent sometimes... You really broke it down smartly....

A) Things that are acceptable when reviewing the WPS

B) Best practices for quality WPS's

30 IPM Lawrence? With .072 E71T-8 wire I would regularly use as low as 135 for a 3G cover (say for a 5/16" web), possibly even 125 IPM, probably 135-150 for a 4G cover on most material thicknesses, but for 1G fill or a 2F weld on material of say 5/8" + I would be dialing for 225 IPM.

Would you be specifying a different WFS range for each position?

Maybe you're right Blaster...

My experience with with .063 T-8's and at least for me a pretty high WFS could be easily used for vertical grooves, pretty close to the top of the manufacturers range....

I never saw a need to get even close to the lower end of the manufacturers suggested ranges....

But I totally accept that your experience probably trumps mine... It's a big world with a lot of welds I've never even thought about.

So maybe a couple WPS's then :)

By 803056

By 803056  Date

Date 09-26-2017 05:01

Edited 09-26-2017 05:04

OK, the post asked the question of "how can the welding parameters be presented." The graphical presentation simply shows a way of presenting the data for a particular flux cored electrode with no mention that it meets AWS. As it happens, it isn't the same electrode the poster is using.

The graphical presentation is simply a different way of presenting the data rather than listing the ranges for parameters of voltage (i.e., 21 to 26V), wire feed speed (i.e., 150 to 400 ipm), amperage, and electrode extension ranges, etc. As mentioned, most of the welders I’ve worked with like this method because it is easy to see that the electrode extension (or CTWD) has to be increased as the WFS is increased. Likewise, the voltage has to be increased as WFS is increased. It helps break the urge of welders to set up for FCAW (or GMAW) using the parameter of amperage.

If there is a need to comply with D1.1, then one would simply show the relevant portion of the graph that meets production needs, i.e., material thickness, position, etc. So, if one needs to hold a 10% variation in voltage range, one would simply present that portion of the graph that includes the range that is appropriate for production needs.

This presentation seems to make it easier for the welders to set the parameters of wire feed speed and voltage. With those data points, it is easy to determine what the appropriate electrode extension should be. If voltage, WFS, and electrode extension (CTWD) are correct, the ammeter should display the correct amperage as indicated by the graph.

I’ve been using this approach for maybe ten years now with the welders telling me, “Finally, a WPS that I can actually use.”

Now, there is a difference between the CTWD which includes the arc length and electrode extension that excludes the arc length. I find that most welders prefer CTWD and many manufactures provide CTWD rather than electrode extension.

Good luck - Al