Hi!

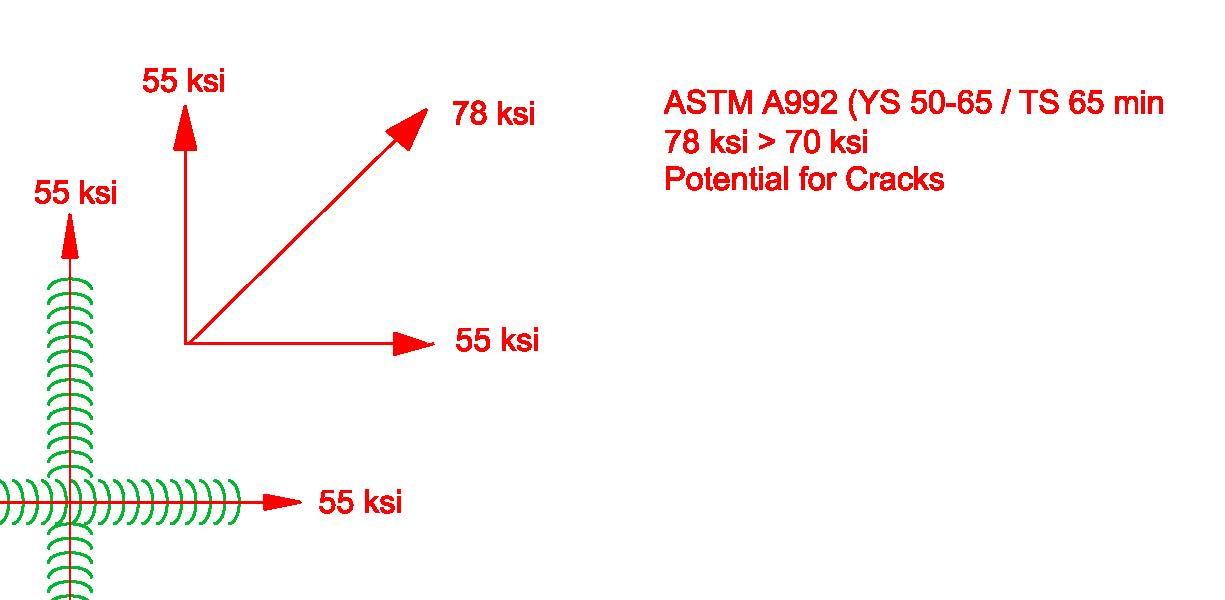

In a beam of a bridge, is permitted weld a stiffener over and along an existing welding in the web?

I need join two pieces of 6000 mm length to form a web with 3000 mm height. But according to the design drawing, over that welding is neccesary to weld a stiffener. I do not know well the codes D1.1 and D1.5, please do you know if there is any prohibition or recommendation about this welding?

https://ibb.co/iofXZQ