About 20 years ago the question came up regarding tolerance for intermittent fillet welds. The interpretation I got for the A2.4 committee is this:

There are no implied tolerance on the maximum size or length of the welding increments. They went on to say:

The size of the weld is the minimum, with no maximum.

The length of the weld increment was a minimum, again with no maximum.

The maximum unwelded space is simply the pitch minus the increment length.

As long as the weld size meets the minimum, as long as the weld increment is no less than the length specified, as long as the maximum unwelded space isn't exceeded, the intermittent weld is acceptable.

Everything else is a workmanship issue that is beyond the scope of the intermittent weld symbol. If the exact location of the weld is a concern, do not use the intermittent weld symbol.

So, that being the case if the specified weld size is 1/4-inch, the size is acceptable as long as it is no less than 1/4 inch.

If the length is specified as 2-inches, the weld is acceptable provided no individual length is less than 2-inches.

If the pitch minus the length is equal to 2-inches, then no unwelded space between adjacent welds can be more than 2 inches.

If the weld is continuous for 6 inches, then there is a 1 1/2-inch unwelded space, another 4-inches of weld and 1 3/4-inch space that is repeated for the length of the joint, it meets the requirements of the intermittent weld specified as 1/4 by 2-4.

Again, as I was told, A2.4 is not a workmanship standard, the fabrication code covers that aspect of welding. So, in the case of D1.1, can the weld be undersized? Yes, per table 6.1. That is the applicable tolerance for size. Can the weld be shorter than specified? Clause 2 includes a statement that the weld length specified shall not consider unfilled craters in the length calculation. I take that as meaning I only consider the weld length that is full sized and disregards "cold starts" and unfilled craters.

The intermittent weld symbol is intended to ensure the weld is "strong" enough to transmit the load from one member to another. The definitions provided ensures that goal is met. If the welder makes the welds bigger, longer, or closer together it is not going to degrade the load capacity of the joint. The goal is met.

If the goal is to have the welds located in specific locations, the intermittent fillet weld symbol is simply not the means of specifying the weld.

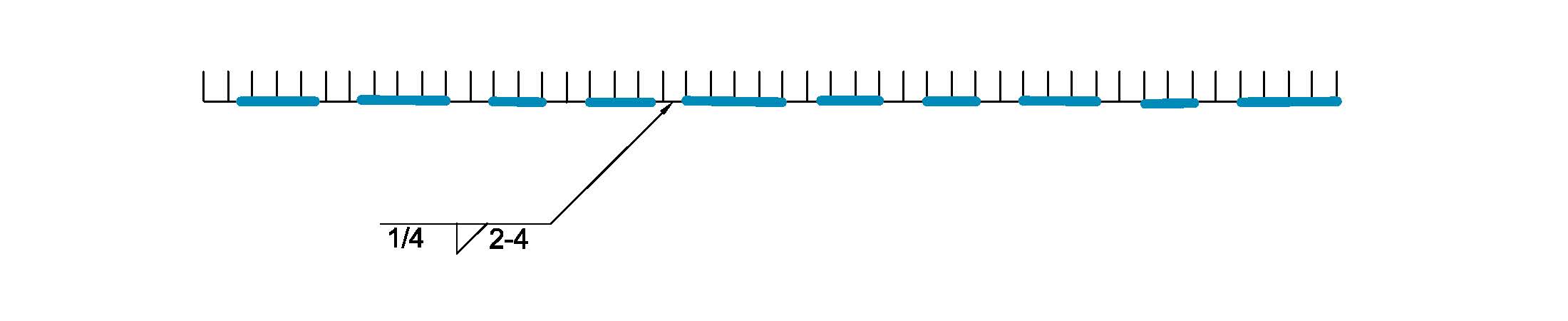

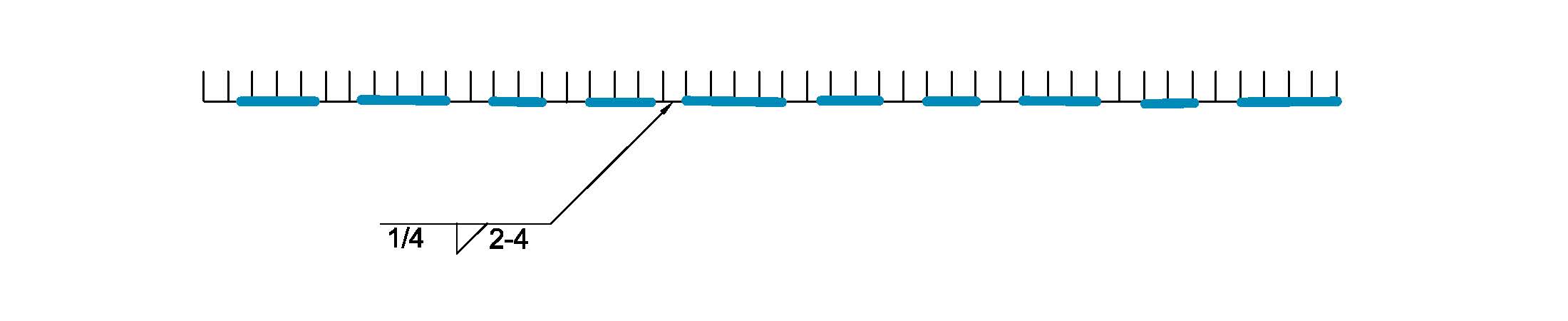

The embedded graphic depicts what I've attempted to say. The question is, "Does the welds depicted meet the requirements of the welding symbol?" Ask the following:

Is the weld size of each increment at least 1/4-inch? If yes, it is acceptable.

Is the length of each increment at least 2-inches in length? If yes, it is acceptable.

Is the maximum unwelded space between each increment no more than 2-inches? If yes, it is acceptable.

If the response to each of the 3 questions is yes, the requirements of the welding symbol are met and the welds "as built" are acceptable.

What if the weld is continuous from one end of the joint to the other? It is still acceptable if the weld size is at least 1/4-inch.

Welds that are too big, too long, or where the spaces are too short are issues of workmanship. Workmanship is not a consideration of A2.4. Issues relating to workmanship must be addressed in the fabrication document, i.e., D1.1, D17.1, etc. If the issue isn't addressed, it isn't an attribute evaluated by the inspector. The inspector doesn't decide what criteria is applicable or the attributes to be evaluated. That is determined by the fabrication document.

Al

Excellent Al!

Ran into this issue a couple of weeks ago. Inspection wanted a tolerance of intermittent welds. It's still on the back burner, but your post will certainly help in clarifying requirements.

Tyrone

I agree....over welding is usually not an issue(just an unnecessary expense), unless the extra weld interferes with the fit or use

Al,

I appreciate your reply to my post...

and I agree with you 100%

with that being said, I have one or 2 inspectors that say "the weld length is the minimum, but the pitch HAS to be there."

basically what all this boils down to, is we was trying to implement a shop standard with intermittent fillet welds.

our prints only call out the length and pitch. no notes in the tail specifying weld lengths on ends.

trying to make every part look the same when finished, by whichever welder welded them.

example - 2"-4" on "X" length.....if it works out where there is not a weld on the end, the parts would look different if a left handed person welded them versus a right handed person.

so we used the formula to SHORTEN (not lengthen the pitch) to create evenly spaced welds and equal welds on each end.

example, 2" - 4" may end up being 2" - 3.75" and that way, no matter who welded the part they would get the same result either way.

and I got some CWI's pushing back saying they are not to print because its less than the 4" stated on the print.

and I cant find anything in the code book to prove that it can be less than 4 and still meet the print.

its getting really frustrating..:)

so any help is greatly appreciated.

I really miss the 'LIKE' button at this point. Excellent.

To the OP, you can't fix stupid. And you can tell them I said so. It isn't that complicated to figure out from the applicable codes. A2.4 and content in the WIT that was so fully taught in the seminar to get their so called CWI certification (without needed qualification) covers this. Every seminar I have sat through taught this. It isn't even Weld Symbols 101, this is kindergarten material.

Another note, at the ends (notice Al's sketch) you don't NEED a weld IF the space from the last fillet to the end does not exceed the space limitation before the next fillet is to begin.

Having said that, I know many shops who will put at least 2" at the end regardless just to make sure a customer's inspector or building authority inspector does not get into a controversial mess over it.

He Is In Control, Have a Great Day, Brent