Well, I think your analogy is totally invalid, since Craftsman (Sears) never made any product in its existence, and simply marketed the brand, and had numerous companies make everything for them(some, like Harris, who made low-priced OA equipment for them for many years, were excellent quality). However, in market share of OA manufacturers, the Dillon/Henrob concept never really took any of the market from Victor, Air Liquide, Purox, Uniweld, Smith, Harris, Forney, etc. or any of large European companies ... in almost 50 years. In fact, in my 70 years of welding experience, I never encountered a single LWS that carried this torch, or, any other company that tried to sell, at a high price, "all you need" to OA weld, without including regulators and hoses.

However, the above has little to do with your problem, and I said I would deal with it in another thread.

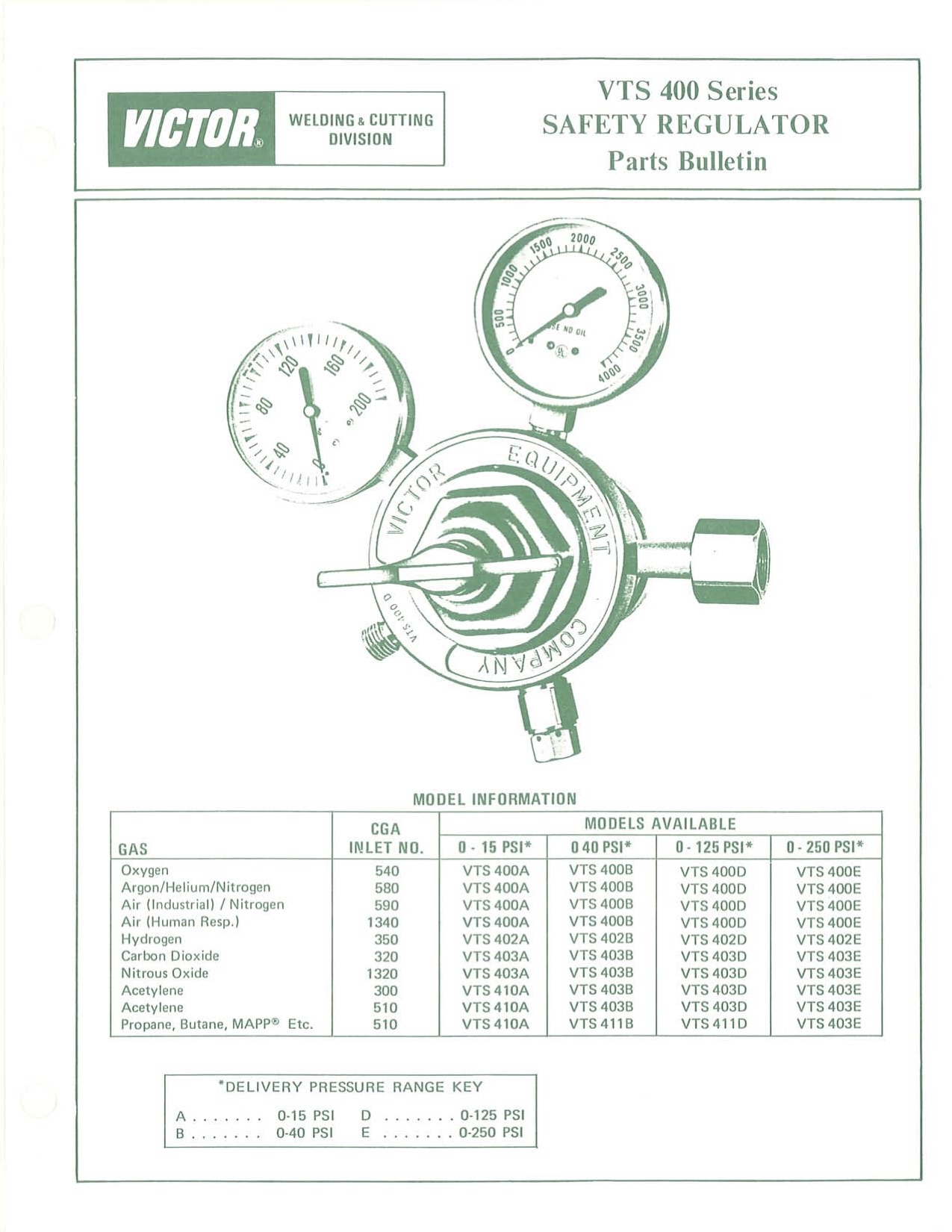

If your regulators are Victor 400 series, they are good medium-duty regulators which were used for a variety of gases, and there are kits still available to overhaul them, and have them working like new, while a little brass polish - elbow grease can take care of appearance. You might pay $200 each for similar quality (there is one on eBay now for $69 untested), What I think you have is a gauge scale problem, not a regulator problem, that is caused by the low pressure used in the DH torch.

Below, you can find a 400 seres blow-up and parts list, dated 1977. Can only post one page at a time, so, let me know if you want to see the rest. Are yours A,B,D, or E, range?

BTW, I notice the Detroit site is making a massive price cut to $ 416 US, Canadian price, remodeling their Website ("Weld Like A TIG!... Cut Like A Plasma!..."), and they are now putting out what looks like a completely conventional torch, as well (WITH hoses and regulators).