I guess there is a confution, Heat Tretable Alloys can't recover strenth with passage of time.

Theres is an Research: Malin, V., Study of metallurgical phenomena in the HAZ of 6061-T6 aluminum welded joints. Welding Journal, 1995: p. 305s-317s.

There is the solution

Francisco is right!

I was totally off base with the notion that the chart applied... The chart does not speak to "as welded" conditions.

Tony Anderson CEng from Alcoa/Esab set me straight, in part this is how he explained it:

"Most 6061 is welded in the -T6 condition, however, regardless of the temper, when we weld on the 6061 material we change the temper. If we weld on -T4 or -T6 we will typically partially anneal the HAZ from the heat input during the welding operation.

Because the HAZ is no longer in the solution heat treated condition (but partially or fully annealed) after welding it will not naturally age.

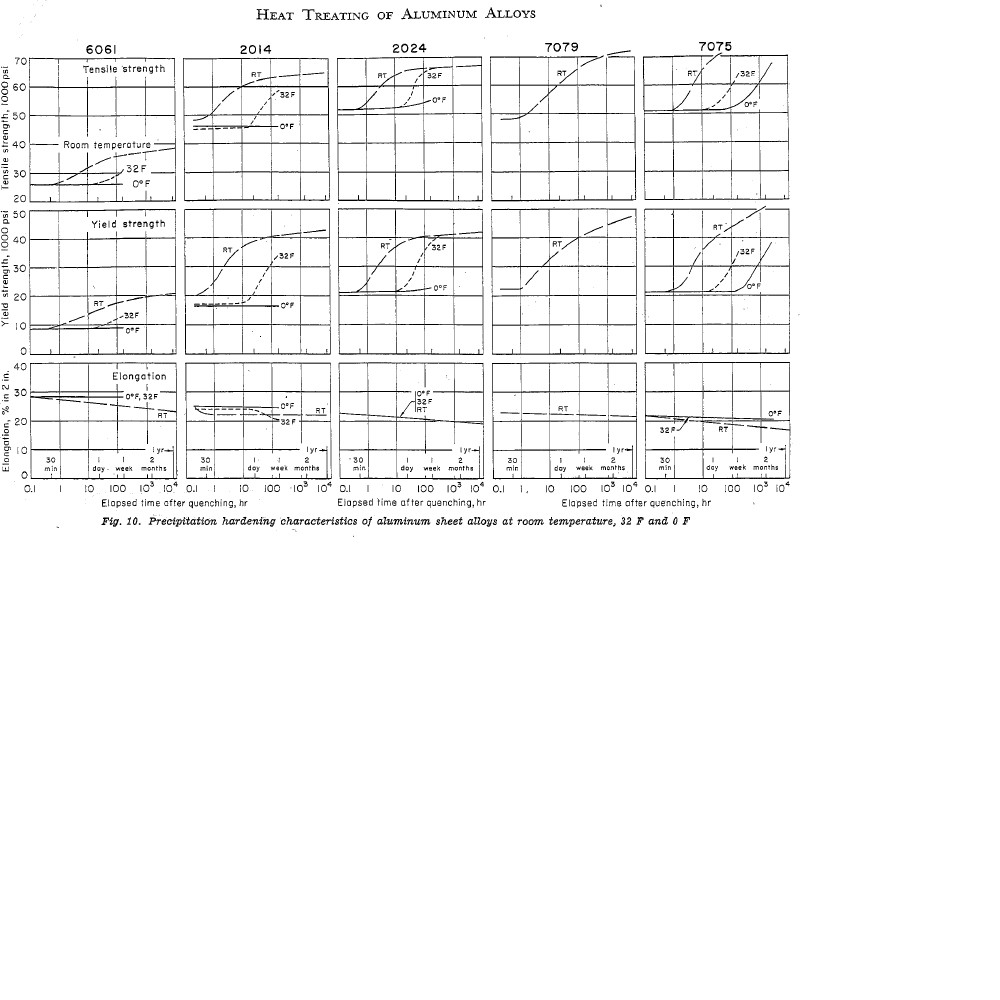

If you take a 6061-T4 (solution heat treated) material and allow it to stand at room temperature after heat treatment, it will naturally age in accordance with the charts that you have.

However, if you weld on a 6061-T4 or a 6061-T6 you will change the heat treated condition of the HAZ (from solution heat treated and naturally aged -T4, or solution heat treated and artificially aged -T6, to over aged and or partially annealed) and lower the strength of the HAZ. The HAZ will not regain its strength through natural aging.

As for the use of a heat treatable filler alloy (4643), this will not change anything in the HAZ, unless post weld heat treatment is performed."