Dear Allan,

Dear Sirs,

although I had replied to the terrific information coming from you all - thanks for that - I have deleted this mentioned first response again (fortunately it was possible!). Reason was, that I thought to have understood when I had read what has came first from Al and Gerald. But afterwards I was - forgive me - a bit uncertain if I had really understood...

Therefore please correct me when I am wrong:

- There are different Standards or Codes, respectively, being used in the United States of America i.e. ASME and AWS.

- Both dealing with the terminology "Penetration" and "Fusion" but having slight variations in regard to their interpretation.

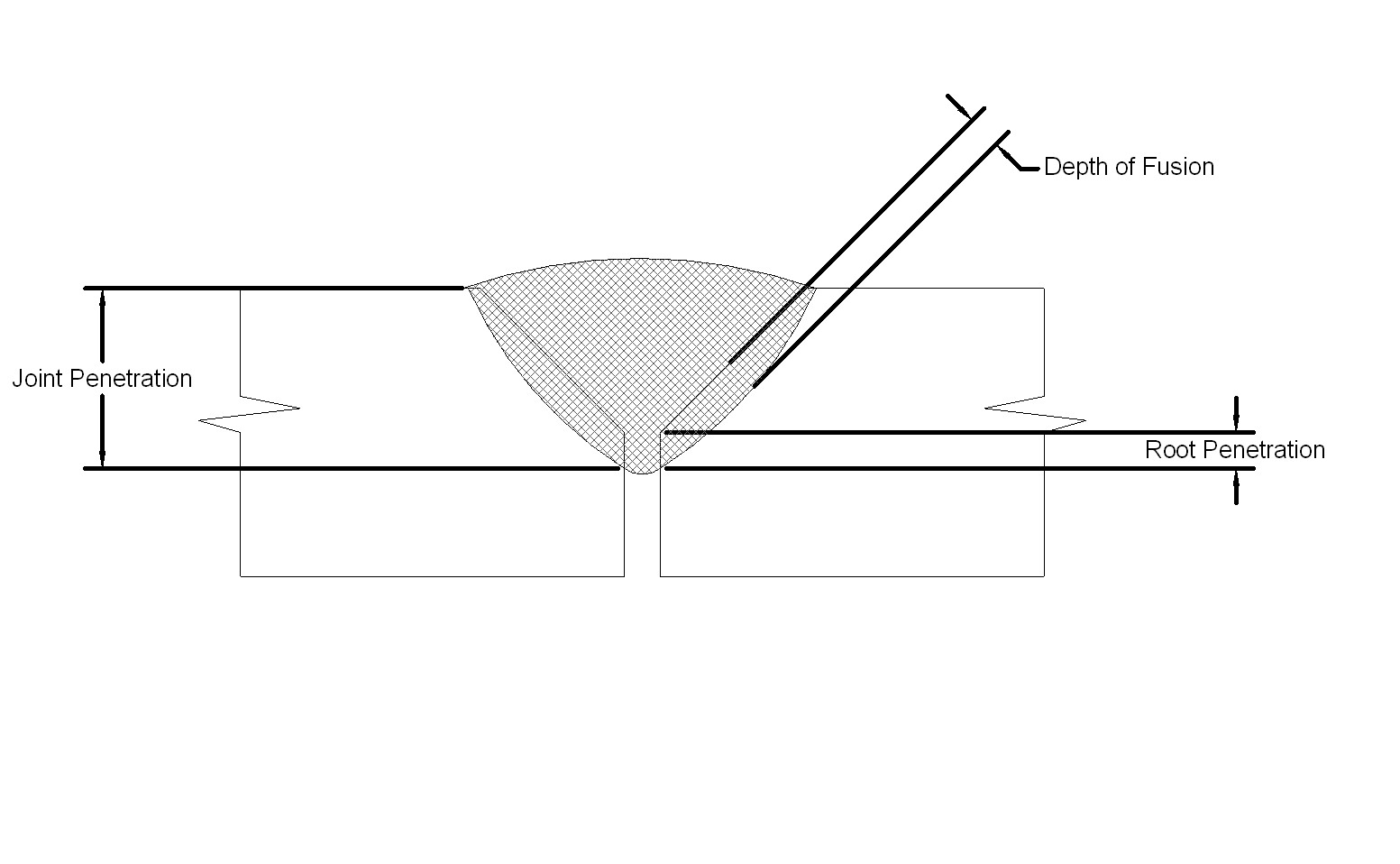

- Whereas "lack of fusion" is strictly prohibited in all* (?) cases (relating to the excellent sketch coming from Al), "lack of penetration" is allowed under specific circumstances. This by all means is comparable to the German/European Standards.

- However, in some "real world" cases also a personal interpretation of "penetration" and "fusion" can take place, since actually both, "penetration" and "fusion", do mean the same, in an extended sense.

I hope that I have not complicated the topic too much.

Believe me or not!

I have received just a minute ago the February's AWS Welding Journal. It was the first time I haven't received it punctually since I am a AWS-member. Thanks to the great Rhenda Mayo from AWS, they have immediately sent another copy of the journal which I have received now, just a little too late, but nevertheless it is here! And what should I say...

By reading the Research Supplement (I love it) article "A Methodology for Prediction of Fusion Zone Shape" I could see what we are currently discussing about. It is... crazy!

Well and what could I recognize? Likewise there the terminology is a bit confusing (at least for me). Please see also:

http://files.aws.org/wj/supplement/wj0207-35.pdfWhereas within the articles "Introduction" the term "Fusion Zone" is being used by the authors, within the Figure 1, the term "Penetration" is used in coherence with "Fusion".

I hope I am right when I assume that this would cover the last stated point of "real-world" cases where the interpretation of "Fusion" and "Penetration" is lying in the personality of the viewer, isn't it?

Thanks and regards,

Stephan

* In regard to Shane's topic. Is there a differentiation of "lack of fusion" between e.g. single "weaved" layers of a weld-cross-section and the "lack of fusion" on the e.g bevels of a weld-joint? Is the first allowed - since it might be interpreted as a "lack of penetration" - and the latter not - since it should be interpreted as a »pure« "lack of fusion"?