I hate to bring confusion to the discussion but the Millermatic 35 is a Multi Tap mig (without a voltage control knob) with a true voltage sensing feeder and will not produce spray transfer no matter what wire or gas you use.

Secondly... Carbon Dioxide 100% is the highest energy shield gas in the short circuiting transfer mode (The only mode the Millermatic 35 can produce). Deeper penetration with a slightly higher probability for spatter, although spatter free welds are quite common.

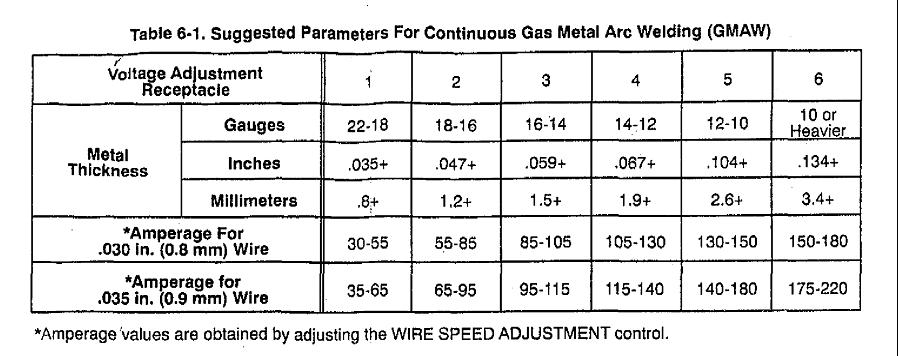

Under the "Hood" of your Millermatic 35 should be a Tap/Gas/Wire diameter/wire fees speed/Sheet Thickness Gauge chart... You will see exactly what Miller recommends for the best combinations of wire and gas. These recommendations are very accurate.

The Millermatic 35 was designed to run both C02 100% and 75/25 Your C02 will work fine, The argon mixes will produce slightly less penetration (which is good in the sheet metal arena) The 90/10 at work is probably targeted to minimize burn thru on sheet metal, or could just be a good versatile Short Circuit/Spray choice all around.

Allan is correct that the 0.030 wire tends to run a little better with the Millermatic 35 but it is designed to run 0.035 wire as well.

Bodyshops would wrestle in the streets to get their hands on your 1970s eara multi tap mig.

Millermatic 35

Check Table 6.1

http://millerwelds.com/om/o1301q_mil.pdfMillermatic 35S

http://millerwelds.com/om/o1301b_mil.pdf