D1.1, Fig. 3.4 shows a B-U2a-GF joint is allowed to have a maximum root opening of 3/8" with a maximum of 30 degree bevels with an allowable fit up tolerance of +1/4" which would translate into a maximum root opening of 5/8" worst case scenario. The worst case actual documented and CWI inspected joints I have in the field have a root opening of 1-1/2". The contractor QA Manager has placed a 1/4" flatbar down the middle of the joint and claims this qualifies as back to back B-U4a-GF joints and is leagal under prequalified WPS requirements. The Contractor's design engineer has signed and sealed this deviation and their so called welding engineer (they have submitted no qualifications for this guy) has accepted this condition as a prequalified joint also. I have rejected this line of thinking and I am requireing him (and paying him extra)to qualify a new WPS under the rules in section 4. I could find nothing to dispute this other than the code requires all of the requirements of section 3 be met to maintain prequalified status and Figure 3.4 depicts no "back to back" prequalified joints. Please give me your thoughts on this?

Should I report this kind of incident to AWS to consider sanctions or revoking his CWI certifications?

I don't know whose qualifications you'd get revoked; the design engineer and welding engineer have no certs. The CWI who initially inspected the weld? Talk to them first; find out why they thought it was acceptable.

I agree that what they're saying is crap. I guess he's saying that the 1/4" bar serves the same function as the bottom piece in the B-U4a-GF figure. There are a number of things wrong with this picture. One is that there are going to be through-thickness stresses induced in that piece of flatbar, and if the stress is already transverse to the weld you could have trouble. He also may be violating some considerations for weld size vs. material thickness. And is he doing a full pen weld from the 1/4" bar to the flatbar, or is there going to be a 1/4" unfused region against the backing bar?

Not to mention that anyone with half a brain can see that's not two back-to-back welds, that's ONE weld with a large piece of trash in it. It's weld slugging, not a connection redesign.

Is there an Engineer of Record here, or does the contractor's engineer (hardly an independent party) get to have final say on everything?

Hg

By 803056

By 803056  Date

Date 12-12-2007 21:11

Edited 12-12-2007 21:14

There are corrective measures that are permitted by AWS D1.1 that would not provide you with a basis of insanity charges against the QC manager or the CWI involved.

Does the fabricator's QC manager or "engineer" have a P.E. stamp? If not, their opinion wouldn't carry much weight in my decision making process. Where is the owner's engineer and what is their posture in this situation? I assume you represent the owner. Don't buy off on the repair if it causes you heart burn and pass your concerns up the line for resolution. Ultimately it is the owner (or his engineer) that has to be satisfied the proposed remedial action is viable.

The amount of detail provided by your post doesn't tell the whole story. What is the structure? What is the degree of restraint? How thick and how long are the members? What is the orientation of the flat bar that is to be used as a "spacer"? Is the flat bar composed of the same material specification as the members being welded? What type of connections are there on the opposite end?

I don't know that you could file charges against the CWI for stupidity. On the surface this sounds like a case of negligence on the part of the CWI, but as an employee, and one that's on the lower end of the corporate totem pole, he may be simply over ruled by upper management.

Al

The 1/4" flat bar down the middle of the joint is a new one on me. Anything outside the parameters of the prequalified joint details, or the prequalified joint details tolerances, are not in accordance with the requirements of D1.1 and are rejectable, as you already know.

If their so called welding engineer is not the EOR, they are in further violation of the code. A wall full of plaques and degrees, and all the welding knowledge in the universe will not change that. Only the Engineer of Record for the structure has the authority to add to, detele from, or modify any requirement in D1.1, because he/she is ultimately responsible for the integrity of the structure.

What stops them from buttering both sides of the joint until they achieve the proper root opening?

AWS D1.1:2006, 5.22.4.3 and C5.22.4.3 permit this and you could still use the prequalified joint.

Root opening are seldom "as detailed" due to variances during erection.

Approval from the EOR is still required, but it gives you a fix/repair that is viable without resorting to an off the wall scheme.

John,

The poster said the field root opening is 1 1/2". Unless I'm missing something, the maximum correctible root opening per 5.22.4.3 is 3/4", but again, the EOR could still approve a correction. That would be a better alternative than splitting the joint with a piece of flat bar.

I didn't catch the 1.5" root.....

if you are allowed to conform to the farm code this would be acceptable. other than that, they are seeing what they can get away with

Thanks to all for verifying my sanity. I appreciate your inputs. The EOR is employed by the Contractor and did seal the repairs. It's Design/Build. The so called welding engineer works for the Contractor also. You are correct..Iam the Owner. I am forcing them by way of Change Order to qualify the procedure per Section 4 so I can be assured of the mechanical properties of the joint. I actually don't hold out much hope the procedure will pass. If it doesn't I'll have all I need to force them to repair all of these joints. There are 42 of them. My take on all of this is their "Professionals would sign off on pixie dust if they were directed to.

I forgot to mention, concerning reporting of the CWI to AWS, this is part of QC1 section 8 and 9. For a CWI to behave in this manner cheapens what we all have worked so hard for.

You still haven't told us what the structure is. If it is a building, you may have to comply with the building code. That being the case, you can involve the local and state building officials. That may get the attention of the your fabricator.

Qualifying the procedure isn't necessarily going to replicate the field conditions or joint restrain of the connections involved.

As mentioned by JW, the ends of the members can be built up with weld deposit prior to assembly within the limits of AWS D1.1.

You didn't answer any of my questions, so the help offered is limited to what we know (and that aint much).

You seem to have a bone to pick with the fabricator's CWI. He's the low man, why don't you go after the PE? He's the man calling the shots.

Al

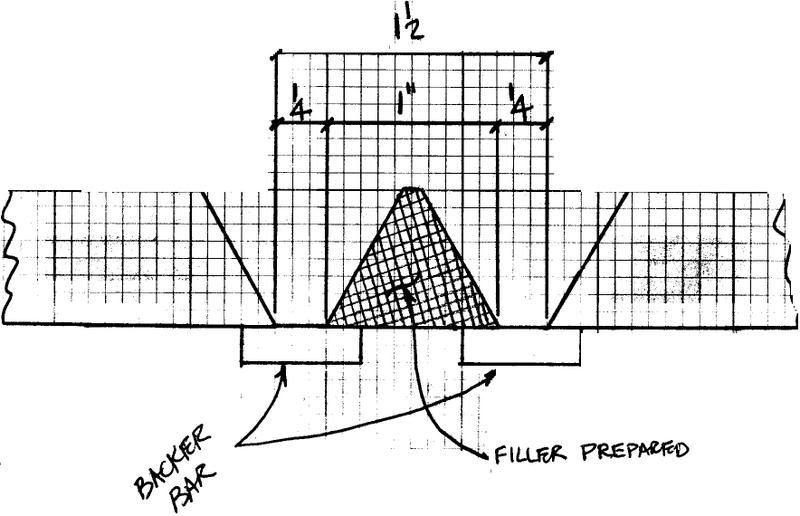

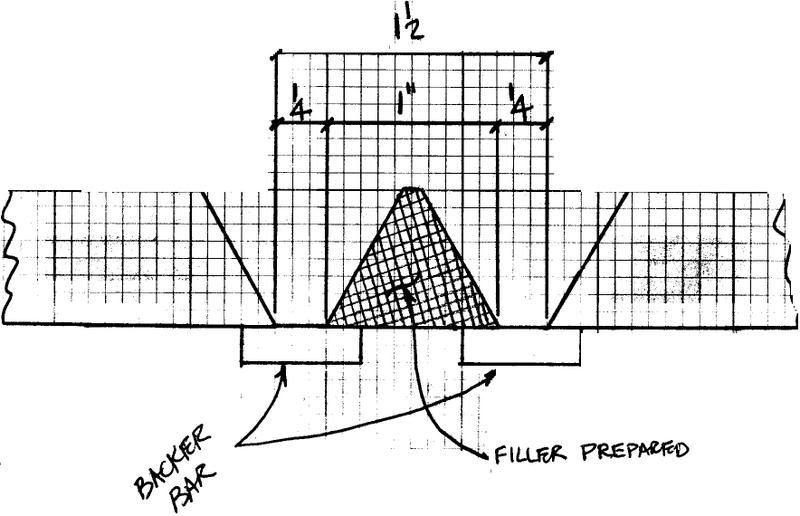

If you need to bring the joint back into tolerance and a scheme is allowed, give this a looksee....how about machining/sawing a piece of flatbar that is the same width as the flanges keeping the grain in the correct direction...but machine/saw the flatbar to a 1" length x flange width and prepared with your 30* bevel on both sides (this gives you the 1/4" root opening and 60* included angle for both joints). This would give you the same joint as was originally designed, sort of...if you weld each joint individually and allow to cool to ambeint, before welding the second, only use the backing bar underneath the root of each joint. Grind the caps flush and thoroghly UT to ensure soundness. I hope I was able to convey my thoughts with this description.<flame suit on> BTW, sketch not to scale

That is about as unconventional as I've heard of in awhile. I would think though that if the EOR signs off on it, its good to go.

And actually as far as the qual is concerned I would be surprised if it didn't pass. That is, provided the bar stock has adequate strength, and good fusion has been achieved by the welder throughout. But that always the case with quals.

I really don't see anything inherent in this joint design that would cause it to fail under elongation or tensile testing (though the perpendicularity of the bar stock weld interface in relation to the bend axis might be your best bet-or though thickness bar stock elongation(Z axis)). So if you're hoping that testing will assist your cause you might be disappointed. Square grooves, narrow grooves are tested with success everyday.

Heck, I'd test it just outa curiosity.

Bar stock Z axis elongation-thats the ticket!!

If this puppy's got elongated sulphides or laminations your in luck!!

Didn't tell us what grade of material the flanges are...flat bar is A36...will he need a 50ksi plate to match? If he(the welding contractor) used an A36 flat bar with a ASTM A572 gr 50 beam flange...that might not fly.

John, I gotta tell ya that's a very interesting "fix" you came up with. Seriously, would that really work. In theory it sounds good to me and looks good on paper, it's just that it's so far outside the box thinking that I can't quite get my whits about it, (granted I just spent 2 hours driving what normally takes me 25 min due to the snowstorm up here). Have you ever done a repiar like that. As far as us in the shop, if that ever happened, the fitter would be exccorted towards the nearest exit, but I've heard stories about what "may" have happened in the field. Chris

The base material is S400 (Japanese equivalent to A36) and the flatbar is A 36. The structure is a coal silo at a new powerplant. These welds occur where the bottom cone attaches to the structural support girder which holds both the cone and the upper barrels and occurs on 7 seams around the circumference of the cones. The silo barrels are 80' tall so they will hold quite a bit of coal (weight). All of this weight will be concentrated on this bottom cone. By the EOR sealing the repair I believe he is accepting the joint but is under the perception the mechanical properties and welding of the joint will be qualified per D1.1 section 4 requirements. Due to the effects of welding on the heat affected zone there is no thickness in the flatbar to absorb this heat and remain within the maximum interpass temperatures (there was not monitoring by the contractor). If the weld passes the procedure qualification I will accept the joints as welded as my concerns will have been answered as to the weld properties. To be honest, I would have felt better about this if they had welded the entire joint as opposed to installing the flatbar.

Nah, if they had a root opening of 1.5" in our shop, (Chris mistakes do happen) but I wouldn't let that fly, we would either cut a foot off and splice the same sized beam and recut and bevel the flanges to get the right root, or swap out that beam for another if we had one in stock and use that beam for a shorter member somewhere else....it really depends on what the EOR will allow.

John,

Good point if the bar is A36. He didn't say. The flat bar could be 572 or 529. In which case the base mechanicals might easily be there.