John,

100perpen,

if you don't mind, I felt reminded on another interesting thread, discussed a time back and initiated by our appreciated fellow Chet Guilford at that time.

It has dealt with Welding Symbols based upon Euronorm EN 22553, please see also:

http://www.aws.org/cgi-bin/mwf/topic_show.pl?pid=71080#pid71080We have discussed this topic quite intensively and in particular Al (803056) has contributed loads of excellent stuff to this.

Since EN 22553 is however equivalent to (ISO 2553-1992: Welded, Brazed and Soldered Joints - Symbolic Representation on Drawings), I hope that 100perpen might find somewhat helpful within the thread mentioned above.

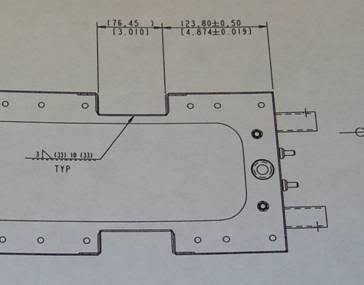

However, as far as I can interprete the picture attached by 100perpen, the fillet weld's (welded on the near side) thickness is 3 mm (as you assumed ~ 1/8") but being measured by the "a-size", see also:

http://www.aws.org/cgi-bin/mwf/topic_show.pl?pid=71316#pid71316but not the US-American "omega-size" (z-size).

The (33) 10 (33) should normally describe the seam lentgh(s) which is though really hard to recognize upon the part to be welded by the picture attached.

Perhaps this can additionally help a bit...

Best regards,

Stephan