By 803056

By 803056  Date

Date 10-24-2009 15:26

Edited 10-24-2009 15:34

Quality control is less costly to the employer than a single failure that can cause injuries, loss or life, equipment failure, loss production, loss profits, and loss of the business (read bankruptcy).

Codes are developed over time and changes to those codes are often tied to lessons learned from failures. While we in the welding community can learn how to prevent failures, the companies involved with the failure may not have survived the aftermath and resulting civil actions and/or criminal actions.

There is nothing dry about some sweaty assed welder on a summer day. The pockets of the welder are not environmentally friendly to those covered electrodes that are required by code and common sense to be kept dry. Let that welder that claims his pockets are dry run his hand up and down the cleavage of his butt cheeks or between his thighs and then tell you there is no moisture and I’ll show you a final check and a pink slip that says “Fired for insubordination and plain stupidity”!

Amongst the employer’s responsibilities is the need to provide proper work instructions to the employees to ensure the requirements of the customer’s purchase order are fulfilled and the requirements of the applicable welding standard are met. Once those instructions are issued, be they right or wrong, the employee’s responsibilities include following those instructions unless there is a recognized danger or health risk involved. If the employee will not or cannot follow the work instructions then it is incumbent on the employer to address the situation. Different states and different countries have different labor laws on how disciplinary actions are handled. In some cases the employee has union representation, but in any event the employer has a responsibility to take the necessary action required to ensure the work performed meets the requirements of the purchase order.

I have found that simply pulling the certifications so the welder can no longer weld can be the action required. If the welder isn’t qualified for the work he or she can no longer work on the projects requiring such certification and it may result in reassignment to a lower pay grade or termination.

Covered electrodes, bare electrodes, or tubular electrodes have to be protected. The work instructions developed by the employer should address how the required level of protection is to be achieved. Covered electrodes should not be “stored” in the welder’s trouser pockets. Bare wire should not be left out on the work bench or beside the work bench where they are exposed to the grit and grime of the shop environment. Tubular electrode (or bare electrode) should not be left on the machine’s wire feeder for prolonged periods if they are not being used for production work for the same reasons bare rod shouldn’t be exposed to the dirt and grime of the shop environment.

AWS states that the low hydrogen covered electrodes must be used within a certain period of time once they are removed from the heated electrode holding oven. Electrodes that have been wet shall not be used. Those requirements are based on "lessons learned" and sound engineering principles.

The production floor is not a democracy. Everyone does not have a vote or a say in how things are done on the shop floor. While the enlightened employer may allow for input from the production workers, management has the final say and those management decisions have to be followed in order to ensure the safety of the workers, safety of the customers, and the safety of the general public. Hopefully, a profit can be made so wages can be paid and stockholders and owners can make a return on their investment. Mavericks that refuse to follow the work rules be they welders, inspectors, or forklift drivers can jeopardize the well being of everyone involved.

I had to visit a lawyer on Thursday to prepare for a civil action against a fabricator/erector because they didn’t do what they had agreed to do. The fabricator/erector is being sued for $250,000 because they made a material substitution and didn’t follow the engineer’s design drawings. It was fortunate that no one was injured, but they will have to pay for damages, loss of profits, and the cost of repairing the facility where the failure occurred as a direct result of the unauthorized material substitution and the subsequent failure of several welds. While the amount of money isn’t huge, it represents a lot of money to the small contractor that employs five or six people.

As for those that take the position that there is nothing wrong unless something breaks, I support their position, because when it does break, I get to testify as an expert witness and that helps pay my bills. There’s nothing wrong with walking on thin ice until it breaks. The codes are intended to help us identify the thin ice, if you chose to ignore the warning, don’t whine and complain while you are drowning in the cold water.

Best regards – Al

I don't get it, who's in control of the workplace?

Do these companies let welders stroll in 2 or 3 hours after starting time?

Do they let them grind without safety glasses or face shields?

Throw their hard hat in the trash and weld in flip flops? Because they are stubborn?

I'm really missing something here but I don't know what it is, because the environments I've always worked in (welding and non welding) the employer set the rules in place and the employees either complied with those rules or was fired.

So somebody help me out and explain what part of this I don't get. All I can think of is that supervision agrees with the welders and won't back up the requirements either. Maybe that's it.

JTMcC.

"Stupid is as stupid does."

Those words seem appropriate.

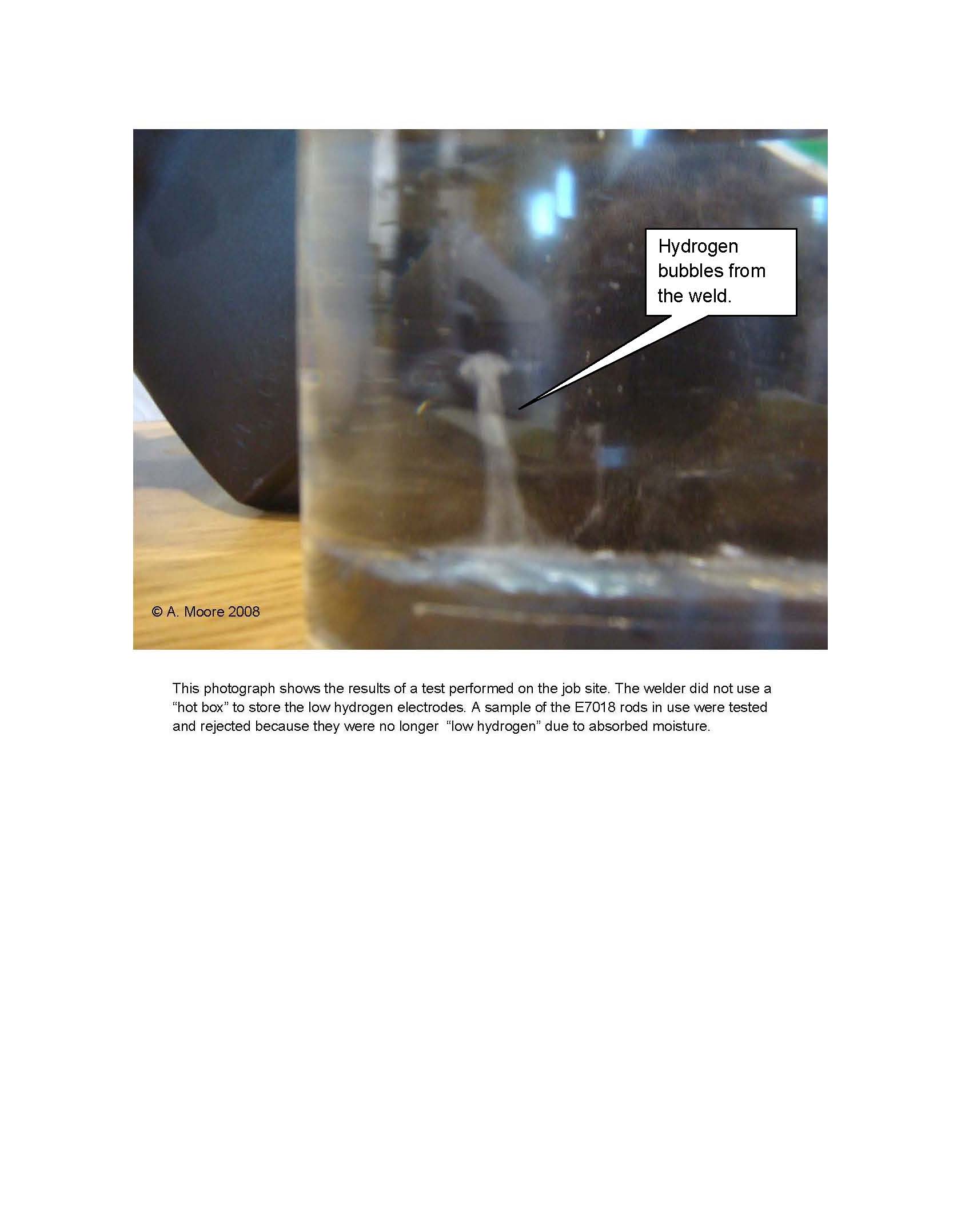

You most likely hit the nail on the head JT. Supervision is lax because they don't understand the implications of using low hydrogen electrodes that have been exposed to excessive amounts of moisture. After all, you can't see hydrogen, you can't taste hydrogen, and you can't smell hydrogen, so how big a problem can it be? Electrodes in the welder's pockets, how bad can that be unless he ate a burrito the evening before.

I have a brother-in-law from the great state of Texas. He say's "Some people are so stupid they shouldn't be allowed to reproduce!"

I've modified his words to say, "Some companies are so stupid they shouldn't be in business." Darwin is at work and thriving in the business world, because "stupid" companies usually fail sooner or later as a direct result of their stupidity.

Best regards - Al

Bert,

It sounds as if you have this handled but I thought I would throw this out there for you and others in the future. If you are working to AWS D1.1 see table 5.1 note 3.

Note 3. Electrodes shall be issued and held in quivers, or other small open containers. Heated containers are not mandatory.

Code requirement.

jrw159