Let's look at the Metrode chart again...

Then we have this...

By Nanjing (**) Date 10-31-2009 01:55

"Henry, dear friend, you still not have not responded to my repeated question. With your vast experience in welding do you consider testing 22%Cr weld metal at 40C acceptable and a normal industry practice?

Please no more rants. Welder 5354 has asked for help and you have become preoccupied with UNS numbers for some reason. Help welder 5354. Tell him if it is ok to use 22%Cr filler in a 40C G48 test and that the problem lies elsewhere. I note everyone else who originally commented on this has kept their heads down. How about you DR Crisi? What is your opinion? Do you recommend testing this filler at this temperature? I feel sorry for welder 5354 who came on here looking for some help and this thread has degenerated into Henry's insecurity about not having a degree and having a liver transplant and basically trying to cover up the real issue that he did not see that the problem was with with the filler wire selection for the test temperature. By the way Henry I do not drink too much... I spill most of it."

Pretty pathetic don't you think??? I say this because I never disagreed with him on the 40 degrees C temp as I say so in this post:

By ssbn727 (****) Date 10-30-2009 01:24

"Nanjing!

I already explained to you why they specified the 25% Cr root pass, and i'll quote it once again... Quote:

By ssbn727 (****) Date 10-28-2009 22:38

"This is more than likely one of your probable culprits the root pass deposit of the ER 2594 (100X) using GTAW...Now I don't know the exact chemical composition of the root pass filler but if there was an insufficient amount of nickel necessary in order to hold the all weld metal ferrite levels low enough for good ductility the conditions as such would certainly be enough to warrant enough IGSCC (Inter-Granular Stress Corrosion Cracking) throughout the thickness of almost the entire weld metal deposit passes to cause enough corrosion and show the pitting marks as well, because if the base/parent metal has a 5 to 6% Nickel content and the root filler doesn't have at least an 8 to 10% of Nickel in order to keep the ferrite number low enough to avoid brittle fracture due to IGSCC that is, so long as excessive dilution is avoided, then IGSCC can originate where the first pass of the flux cored deposit of Supercore (E2209TO/1-4) diluted, and more than likely excessively with the root pass made up of an alloy mix with insufficient Nickel. this is one of many probabilities however slim it may be, I'm leaning more towards excessive dilution due to the higher heat input from the FCAW process... So the next questions would be: What were the parameters used in welding with the FCAW process, and what were the parameters for the GTAW process and finally, what was the exact composition of purging gas used - NOT the shielding gas!!!

I ask this because if there wasn't a slight amount of Nitrogen added to the purging gas this could also have led to setting up the conditions for IGSCC as well as having too many ppm's of oxygen in the purging gas, not the shielding gas!!!

In summary, if there isn't sufficient data bought forth for us to analyze completely to cover all possible scenarios by having all of the pertinent information available to review, then we could come up with all types of possible root causes that may or may not bear fruit with or without complete confidence!"

Then you have the audacity to say this:

"If you read my posts I never said the base material was super duplex."

Well then what the heck is this???

By Nanjing (**) Date 10-28-2009 18:22 Edited 10-28-2009 18:35 Quote:

"I take it that it is 25% Cr super duplex not standard 22% Cr you do not say."

This is when I referred to the original poster's first post on this thread, and btw, the time lines do not lie so, please do not take me for a fool because you'll find yourself caught with your pants on fire if you dare underestimate my powers of understanding how these threads and posts work!!!

Look, I do not disagree with what you think is the probable root cause of why the pitting marks occurred, I just disagree with your blanket statement that the only UNS number for grade 2205 duplex stainless steel is only S32205 because it is clear that I proved not only to you, but to anyone else who wants to notice that there is more than one UNS number for Grade 2205 Duplex Stainless steel which is both S32205 and S31803 as well yet you still fail to agree with me and hold your ground that there is only one UNS number for 2205 grade Duplex stainless steel despite the overwhelming proof I have provided compared to nothing that you have put up so far to counter my assertion. And that is the main reason that you make yourself look so ignorant like a horse with blinders on!!!

Finally I agree if there isn't sufficient Nitrogen or Nickel to keep the ferrite level from rising substantially enough to disrupt the phase balance which is why they probably used the 25% Cr GTAW filler for the root as well as the process in order to control dilution as well as to deposit more Nickel if it was present in the chemistry of the GTAW filler rod into the root so that when the subsequent FCAW filler was to be deposited after wards, the added nickel in the root filler would evenly dilute into the following FCAW passes and therefore theoretically control the ferrite content but, they probably didn't use a purging gas with a slight enough amount of Nitrogen in order to counteract the loss of Nitrogen in the root deposit coalescing with the base/parent metal.

This is more than likely one scenario although, the FCAW filler could also have been made up of the other UNS number of grade 2205 duplex stainless as opposed to the same one as the base/parent metal also.

However, when you kept insisting that there is only one UNS number for Grade 2205 duplex SS, I kept trying to convince you that you were incorrect up to the point where I submitted indisputable proof, yet you still were adamant that there was only one UNS number - is the MAIN reason why I am not only upset with your utter ignorance, but I'm also in fact pizzed off at you for your obvious denial in you own statements in this thread, and that is totally unacceptable. So, if you want to finally concede that you were wrong and ignorant towards what I was attempting to prove to you, and to admit that you did indeed made such statement as the one's I posted above and apologize -I will then be more than willing to accept it!!!"

So, does nanjing even bother to admit that I did not disagree with him on the question as to whether or not the correct temperature was being used or not??? Absolutely NOT!!! Instead, he continued to push the issue without any real basis for even arguing the point he was so desperately attempting to make, sort of becoming obsessed with himself!!! So with that, I decided to "Toy" with nanjing a bit just to see if my suspicions were correct about him needing to go see an eye doctor in order to update his prescription with this response on Halloween no less

By ssbn727 (****) Date 10-31-2009 08:18

"To my dear "Friend Nanjing!" (I am being very Sarcastic when I type this in case you're wondering!) I wasn't planning on replying to anymore of your responses, but you decided to twist e verything around once again!!! You say I mentioned my liver transplant in this thread, and nothing could be further from the truth you poor excuse for a human being wh until now, I only thought that maybe, just maybe you were slightly ineabreated while reading the responses, and then you stoop down to using such a low life tactic is this??? How really pathetic you are!!! Your friend Shane actually compared you to my friend Chuck Meadows as someone who had as much knowledge as he did regarding stainless steels??? You could not hold a candle to him, and I feel bad enough that I even have to associate you in the same paragraph with Chuck who was truly superior than you as well as MAN enough to admit when he overlooked something more than once, or even flat out made a mistake when pointed out to him, and that is something you cannot do as you have demonstrated throughout this entire thread!!!

You want an answer to your stupid and MOOT QUESTION??? HERE IT IS!!! WRITE WHAT YOU MEAN, AND MEAN WHAT YOU WRITE!!! BEFORE YOU CHALLENGE ANYONE TO ANYTHING IN HERE!!! FINALLY, PROFESSOR CRISI ALREADY ANSWERED THE MAIN GIST OF YOUR QUESTION ALREADY SO, I'M JUST GONNA COPY AND PASTE IT ONCE AGAIN FOR YOUR EYES:

G.S.Crisi (****) Date 10-27-2009 07:52 Rating 3 (***)

Being a chemical engineer, I'll look at your problem from a chemical point of view.

First. You say, and paragraph 4.3.5 of Norsok standard confirms it, that the coupon was pickled for 5 minutes in the nitric and hydrofluoric acids solution at 60ºC. Scrictly speaking, pickling doesn't make part of the corrosion test. Its purpose is to remove the dirtyness (oil and grease for example) and the very very thin chromium oxyde layer that exists on the duplex alloy surface, so as to leave the coupon metal clean and pure before starting the corrosion test.

Nevertheless, 20% nitric and 5% hydrofluoric acids solutions at 60ºC is a mighty corrosive environment, so it's possible (quite possible, I'd say) that corrosion on your coupon began at this point. Carbon steel would be eaten away in a few minutes if submerged in that solution.

This percentage of pickling solution is obviously the root cause of such weight losss because the 6% ferric chloride solution by in itself could not dissolve 12 times the allowable maximum all by itself, so the fault lies in the actual percentage of nitric and Hydrofluoric acid used for pickling as the only logical cause for such an extraordinary amount of weight loss!!! So your point is MOOT regarding the 40 degrees C as being the main culprit because a difference of 5 degrees over what is normal industry practice could not account for such a huge amount of weight loss - CAPECHE???

Dear Friend??? Having friends like yourself Nanjing, then who needs enemies!!! As far as the degree is concerned, i do'nt need your lousy excuse for something to wipe my a$$ with - No Thanks!!! I've got Scott tissue which works just fine!!! The filler wire for the FCAW portion is the correct one for alloy 2205 if, and I'll emphasize a big if it was straight alloy 2205... If it was alloy for 2205+ which is formulated for the other UNS number-S32205 then, the FCAW filler would be incorrect because of the slightly different chemical composition which at this point none of us really know what is consists of... If the GTAW filler used exclusively for the root pass only was not of a type with sufficient enough N as well as Ni which also DO NOT know the exact chemical make up of either, and there wasn't enough Ni or any for that matter used in the purging medium along with too much Oxygen in PPM's then it's quite possible, and I emphasize quite possible that all of these scenario's or most of them combined in one combination or another could account for the failure in the corrosion test however, I'm leaning towards the pickling medium being too strong as the actual culprit at this point!!! So there you have it phukhead, err - I mean Nanjing, Come-Mierda, or whatever your name is!!!

In summary, no one aside from the folks who have ALL of, and I say ALL of this pertinent data could know exactly what is the ROOT cause of the corrosion test failure!!! We can only speculate as we do most of the time and that is why we have discussion like this one... Unfortunately, when a person like yourself comes in here tooting their proverbial horn like you did and totally makes such an a$$ out of themselves like you did, doesn't help welder 5354 by being so adamant with your ignorance and then avoid admitting your own mistakes, only cheapens the discussion by the way you pathetically attempted to turn around and deflect your own insecurities towards me!!! that was the straw that broke the proverbial camel's back and it's as simple as that!!! So once again - GIVE IT UP ALREADY!!!

Btw, are you stuttering here as you write this??? Because I've never thought one could such a thing with a keyboard!!! ;-) ;-) ;-) Quote: "I feel sorry for welder 5354 who came on here looking for some help and this thread has degenerated into Henry's insecurity about not having a degree and having a liver transplant and basically trying to cover up the real issue that he did not see that the problem was with with the filler wire selection for the test temperature.' Hmmmm... "with with???" Quote: "By the way Henry I do not drink too much... I spill most of it." Where? In your eyes??? Then it's no wonder your constantly unable to read or pickup everything that is pertinent in this thread :-) :-) :-)

GIVE IT A REST ALREADY!!! IT'S OBVIOUS WHO IS BEING INSECURE HERE, AND IT CERTAINLY IS NOT ME, MY DEAR FRIEND NANJING!!! :-) :-) :-)"

Henry

So what does nanjing respond with? He takes the bait and states the following...

By Nanjing (**) Date 10-31-2009 21:05 Rating 1 (*)

"Henry, my old friend you have at least answered my question at last!: So your point is MOOT regarding the 40 degrees C as being the main culprit because a difference of 5 degrees over what is normal industry practice could not account for such a huge amount of weight loss - CAPECHE???"

Henry if you had any experience at all you would know 22%Cr duplex is tested at 22-25C and super duplex is tested at 35-40C with a norm of plus or minus 2C. This can mean welder 5354 has tested his samples at possibly 18C over the normal temperature. This shows you have no frontline experience in corrosion testing duplex welding consumables. If you decide to reply please cut and paste a welding consumable manufacturer's recommendations for corrosion testing 22%Cr duplex.

I am sure your friend Chuck will be sitting on a cloud somewhere shaking his head at your technically incorrect statements. I will persevere to give advice to you and others on this forum when I can however I do not have much spare time. If you care to reply please keep it brief and to the point. I truly hope you get better soon (and I am not being sarcastic, you need help)." He doesn't realize it, but he walks right into my trap as I respond with this...

By ssbn727 (****) Date 10-31-2009 21:44

"Hah, Hah, Hah!!! You fell for my ruse after all!!!TRICK OR TREAT!!! :-) :-) :-) What I actually gave you were the PRE Numbers for Alloy 2205 and you fell for the bait my Dear friend!!! :-) :-) :-) Yeah Chuck is most definitely shaking his and laughing out loud how you fell right into my trap!!! :-) :-) :-) Actually you can go up to 30 C with Alloy 2205+ so you're not totally correct, but nice try in any event!!! Now please give it a rest because it's a shame to see you making yourself look so obtuse!!! ROTFLMFAO - ROTFLMFAO - ROTFLMFAO!!! :-) :-) :-) :-) :-) HAPPY HALLOWEEN!!!!!!! ;-) ;-) ;-) You do know the equations on how to figure them out, don't you!!! ;-) I mean after all, you should???"

Henry

So, nanjing follows up with this response:

By Nanjing (**) Date 10-31-2009 21:58

"You are trully clueless! Welder 5354 tested at 40C. u say u can go up to 30C. What do u expect to happen at 40C? Henry I am trying to help you, I want to give you the benefit of my knowledge and experience but you will not listen. If you do not want to believe me please consult others,eg DR Crisi (I do not know where he has gone.. maybe in hiding)."

I'll have to admit that my response was rather aggressive and insulting which is probably why it was deleted... So then nanjing responds with this...

By Nanjing (**) Date 10-31-2009 23:14 Rating 1 (*)

"PREN= Cr+3.33Mo+16 N (or something like that, of the top of my head!). Now answer my question. Is 22%Cr filler suitable for testing at 40C? If u think it is please substantiate it. Simple question.. give me a straight forward answer answer." So I respond accordingly with this which does answer his obseesive question on whether or not the G48 Method A pitting sorrosion test should be done @ 40 C or not and I answered it without any ambiguity as far as I can see:

By ssbn727 (****) Date 11-01-2009 03:13 Edited 11-01-2009 09:42 Rating 2 (**)

'I apologize for the late response, but I was celebrating my NY Yankees Baseball team winning their 2nd consecutive win over the Philadelphia Phillies, so I wasn't paying attention as to whether or not you even responded!!! Okay, let's see what you wrote... Hmmm, I thought so!!! You most definitely need to get your eyes checked Nanjing... Why??? It's really quite simple yet ohhh sooo subtle that it escaped your eyes completely and here's what I mean exactly as well as without any ambiguity whatsoever!!! ;-)

First off this is where you misread my question and proved just how important it is for you to get you eyesight checked...Get rid of the the percentage of "Nickel" and you are correct for the PRE Number, as opposed to the PREN Number which is what you thought I wrote so, although I will not be as critical as you were with me, it just proves to me and everyone else again that you need to get your eyes checked my dear friend Nanjing!!! :-) :-) :-)

Okay, now that I've clarified what your problem really is, I'll answer your straightforward question with a straightforward answer (Did you actually think that I would do such a thing Nanjing???)...

NO!!! Why??? Because you'll surpass the critical pitting temperature, or CPT @ around 22 -23 degrees C to a maximum of around 24-25 degrees C with heats that have lower percentages of Ni as well as N & Mo in their chemical compositions in both the Base/parent metals & welding filler metals, and since there are only a few brand manufacturers of both base/parent metals which have slightly elevated amounts of these alloying elements while simultaneously staying within the bounds of what is still considered an Alloy 2205 grade of duplex Stainless Steel, only slightly enhanced when one observes it with appropriate over alloying N, a "smidgen" (which in my book is a really, really small amount in order to increase pitting and crevice corrosion) more of Mo & Ni (which slows the formation of brittle intermetallic compounds as well as increasing yield strength) as well, then combining them with similarly enhanced weld filler metals of the 2209 grade, one can quite possibly increase the level of the CPT only slightly more to about a maximum of up to 30 degrees C and that would only be feasible if cost was not a factor at all!!!

And it would probably require much more welder training for qualifying just to the WPS alone, and then subsequently towards production which would also have to be factored into the overall costs and I don't have to tell yo u how hard that is to convince as well as how rare it is to occur - yet it has in the past on occasion!!! ;-) ;-) ;-) IMHO, I would rather switch to either a richer grade of Duplex, or switch to a Super Duplex grade all together, but that would require approval from both the owner as well as the EOR and that's as possible as it is for one to win the Powerball & Super Seven numbers lotterysimultaneously!!!;-) ;-) ;-)

In summary, for alloy 2205, 22 to 25 degrees C maximum is the recommended CPT for ASTM G48-03 Method A only, before pitting in the weld and too much of the allowable weight/mass loss of the sample is reached even though the increased amount of weight/mass loss doesn't come close to 12 times the amount of weight/mass loss shown in this test since it is also required that the test be interrupted once more than 5% of the total weight/mass has been lost, and this must have happened way before the test reached the 24th hour!!! So this fact, makes me even more convinced that the pickling solution which is NOT required to be used in the ASTM G48-03, Method A corrosion test was indeed a factor in such a substantial amount of weight/mass loss of the specimen in question as Professor Crisi so eloquently pointed out in his previous post!!! The pickling solution really was indeed a factor in contributing to such a substantial amount of weight/mass loss of the specimen in question.

Although, it is quite possible without any regards for increased costs whatsoever to increase the maximum CPT to around up to 30 degrees C if increased scrutiny with respect to the chemical compositions of favorable heats in both base/parent metal as well as weld filler metal were incorporated in order to achieve the increased results of those CPT's before pitting would start show so prevalently as well as such a substantial amount of weight/mass loss. So there you have it Nanjing!!! You managed to persuade it out of me finally!!! ;-) ;-) ;-) Anywho, it was fun watching you react in the way you did durng this discussion nonetheless!!! :-) :-) :-) Promise me that you will go to the EYE DOCTOR??? SEE YA!!! WOULDN'T WANT TO BE YA!!! :-) :-) :-)

Your Dear Freund, (intentionally spelled that way! ;-) )

Henry" Well, it's obvious at this point that I answered nanjing's question already here very clearly, and if you look back at this post (By ssbn727 (****) Date 10-30-2009 01:24)

which I have as my first response in this string of posts which I copied and pasted into this post, it clearly states that I did not disagree with what he was saying regarding the 40 C temperature as well as stating that there may just be other factors, possibilities, probabilities as well, but we do not have all of the necessary data to be absolutely confident in what the actual root cause was why the test failed!!! Okay! So what does nanjing do after my last response in this chronological chain of posts??? Well, you just may find this interesting enough when nanjing responds with this:

By Nanjing (**) Date 11-01-2009 05:49 Rating 2 (**)

"Henry. 40C it was tested at. Just answer my question. Is this a normal temperature for testing 22%Cr? Cut the bull.... you are talking round in circles! You cannot admit you are wrong on this as it will prove you are just a joke once and for all." Now is that anyway for someone to behave themselves after I just answered his question with my previous response??? Hmmm... Well, then all of a sudden -3.? decides to put in his view with this post:

By 3.2 Inspector (***) Date 11-01-2009 07:22 Rating 1 (*)

"He always does that, he simply refuse to answer a straight forward question.

3.2" Well, I must say that these two did rather disappoint me with their lack of observation to the answer I had already given nanjing, so I decided to express my disappointment with this response:

By ssbn727 (****) Date 11-01-2009 09:50 Rating 2.33 (**)

"Now I'm really disappointed in both of you guys!!! I would have thought by now that both of you would have realized by now that I am obviously correct as well as vindicated in not only my observations, but also my own experiments on both of your capabilities, or rather lack of combined capabilities to read properly even as I intentionally used both bold type face as well as italics combined intentional , yet subtle changes in some of the technical nomenclature to no avail even though your friend Shane acknowledged the use of these visual aids, in the hopes that both of you would be able to distinguish as well as comprehend all of my responses to you, and since you have both failed miserably on multiple occasions to become enlightened by my attempts up until now...

I've reached the point where even if I have already given you the answer to your multiple queries directed specifically towards me, both of you are still incapable of articulating it and I suppose it is because of the distinct differences between being familiar with the British, or "King's English" version of the English language which is obviously is quite different than the American Northeastern dialect to be more specific, version of the English language that I use to communicate with just about everyone I know and even most folks whom I do not have any previous communication just fine!!! And it is a shame - PERIOD!!! :-( :-( :-(

However, I will not give up in pointing out to both of you that in my second to most current previous post before this one, I have answered your query as specifically as possible, so all you both need to do is to re-read my last two posts in this thread ,and you should then understand that both of you desperately need to seek the attention of an eye doctor!!!

Here's a tip... All you have to do is to look at the date and time of when my last two posts in this thread by comparing them with this one which will be when I'm finished writing and posting it, my most current post in the thread... Once you are able to figure that out and I pray that you both do, then you will both see the obvious error, or rather lack of sufficient eyesight in both of you at this time!!! ;-) ;-) ;-) Tah- Tah Gentlemen!!! for I am done here!!! Find the answer and do what you will with it!!! :-) :-) :-) I really do not care anymore!!! :-) :-) :-)

Your Dearest Freund, (Once again, intentionally spelled in this manner for your amusement!;-) )

Henry

P.S. I must admit to you both that I have had what I generally considered a rather bizarre, yet amusing time during my attempt to establish a meaningful relationship with both of you during this discussion as it has on many different occasions, reminded me of being spontaneously cast on "Saturday Night Live," the Famous and still running show on late night and can be found in the NBC network of American Broadcast Televison!!! :-) :-) :-) Auf Wiedersehen!!! ;-) ;-) ;-)"

I have to admit that at this point, I almost fell out of my chair more times than I can remember from the comedy exhibition these two were displaying!!! :) :) :)

At this point the thread is continued on page two all the way down to this post..

I know I said that I would not post here in this thread anymore, but after reading the last posts, I could not stop myself from posting this sort of "Play by Play" in order to clarify who said what to whom and when, because sometimes it can be hard to follow the sequence of the posts in chronological order so that the person who reads the thread can get a clear understanding of what is actually going on in the particular thread especially if there is a lot of back and forth going on that only adds to the confusion in trying to find out what is actually being discussed in the thread. ;) So, I hope that by posting this series of previous posts that are part of this overall thread, most of the confusion can be put to rest once and for all!!! ;) ;) ;)

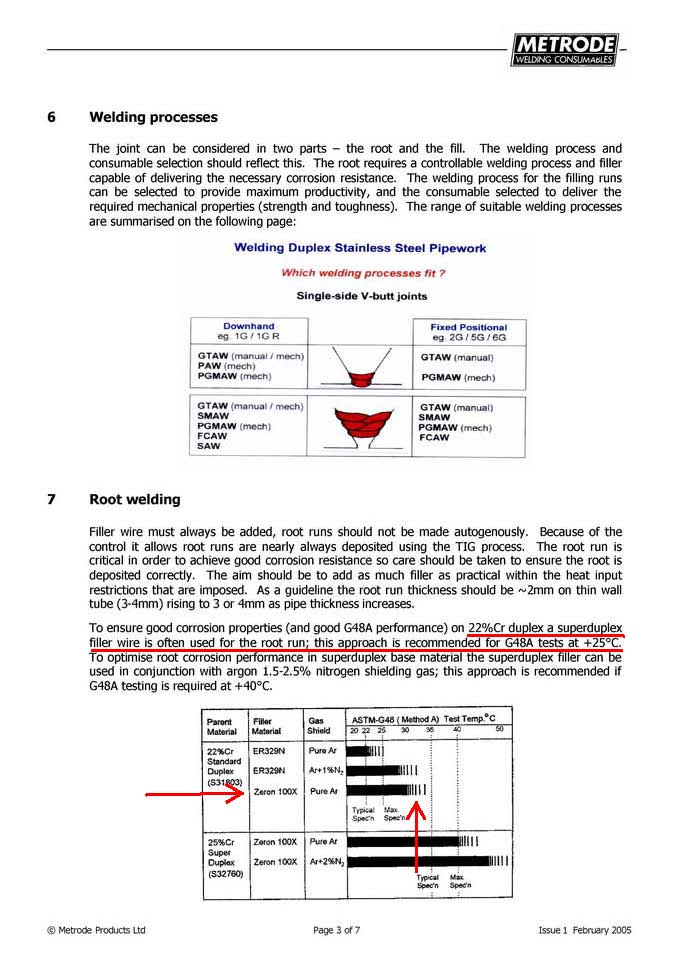

P.S. Please make note of the .pdf file I have attached which clearly shows with the blue arrow head how high of a temperature in C can one expect to pass the ASTM G48 Method A, pitting corrosion test with the coupon being of a 22% Cr duplex alloy (S31803) using a Zeron (25% Cr) 100X GTAW root pass followed by a 22% Cr filler then one will see where I'm getting at once and for all. A very interesting thread indeed!!! :) :) :)

P.P.S. Please use the "Zoom" feature in the Adobe .pdf file, and zoom it up to 150% to clearly see where the blue arrowhead is on the 30 degree C mark, then follow the blue line down as it cuts across the black bar in the graph which clearly shows the CPT beyond 30 C for the 22% Cr duplex (S31803) grade of base/parent metal with it being welded with a Zeron (25% Cr) filler for the root pass only and followed with filling and capping with a 22% Cr filler using pure Argon shielding gas! ;)

Respectfully,

Henry