Hi Mike,

What type of weld inspection job are you working on?

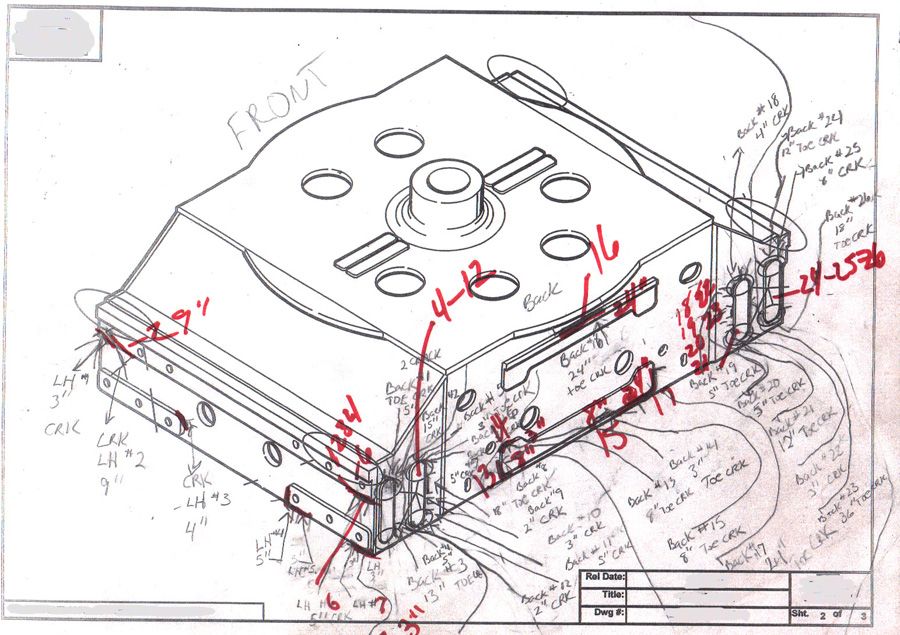

Generally speaking, weld mapping can be done on any drawing where each the welds are identified. Maybe even use some type of matrix and can be used in conjuction with the drawing to sign off on(welder, inspector, NDT, ect.).

Can't send examples because we have enough trouble getting drawings from vendors for ourselves since everything is proprietary.

In general, they can be an assy drawing with weld symbols that reference the WPS numbers.

In the absence of a drawing they can be a matrix table that lists a weld number with the thickness, joint type, wps number, pqr number, and sometimes nde requirements.

Some of our better vendors submit an assembly drawing with weld numbers as well as a table matrix but that is rare.

There is no cast in stone format. The only thing is that the information must provide details on weld number, wps number, pqr number, material type, thickness, and joint design. It is also wise to call out heat treat and nde requirements.

I got one from a vendor last week that had 230 welds and only 3 procedures. It was a thick stack of Excel spreadsheets with a weld number detailed assy drawing.

If you let me know your mailing address I'll send you, as an example, a couple of sheets of the weld mapping of an urea reactor.

They're not in electronic format, just printed, that's why I need your mailing address.

Giovanni S. Crisi

Sao Paulo - Brazil